High-capacity high-power ferrous phosphate lithium power battery and manufacturing method thereof

A technology of lithium iron phosphate and its manufacturing method, which is applied in the direction of battery electrodes, secondary batteries, and final product manufacturing, and can solve the problems of low electronic conductivity and ion diffusion coefficient, poor high-rate charge-discharge performance, and low charge-discharge efficiency. Advanced problems, to achieve the effect of reducing the internal resistance of the battery, superior cycle performance, and solving the effects of gas inflation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

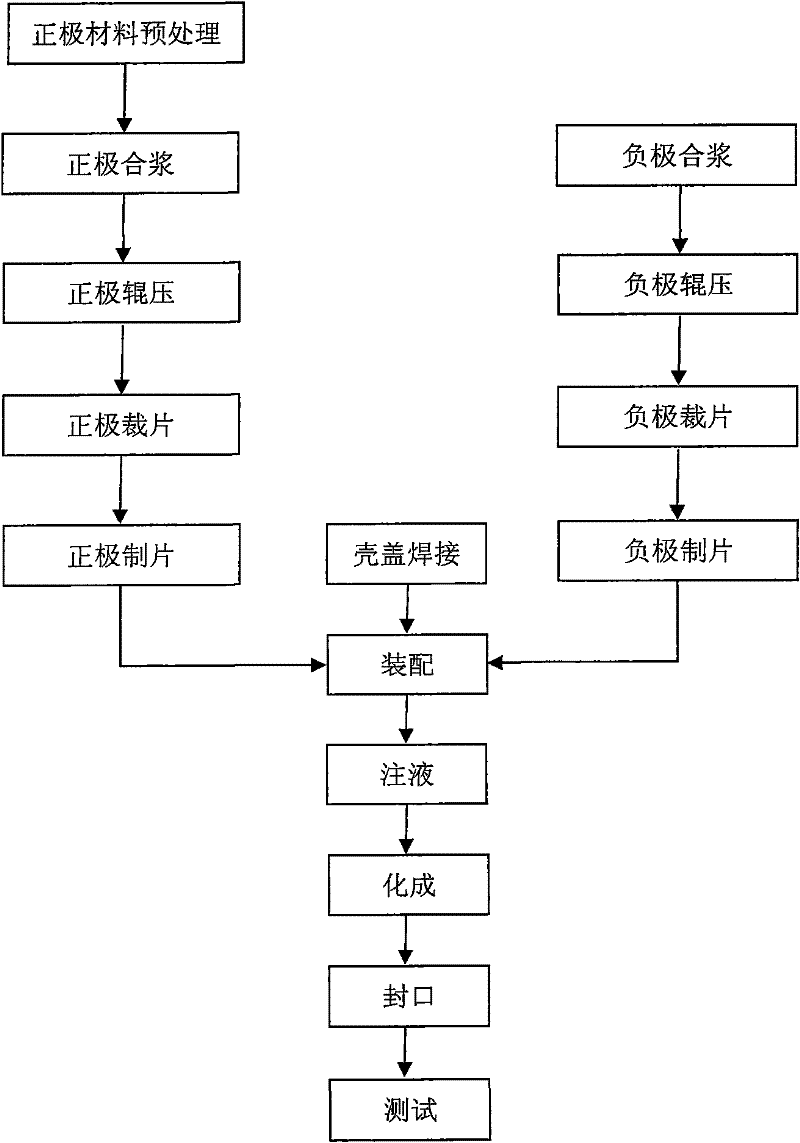

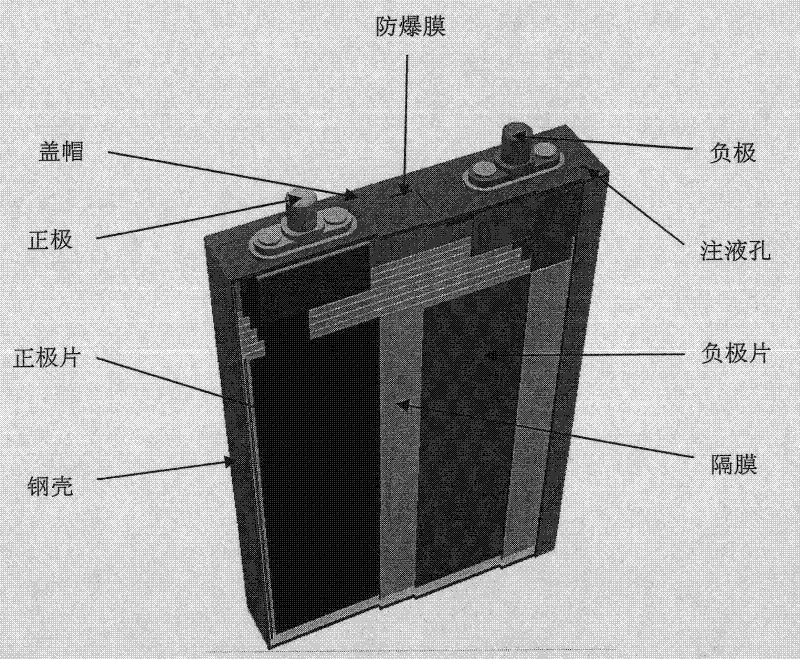

[0023] Taking the manufacture of 1882130 type 10Ah square lithium iron phosphate battery as an example, the selected tap density is 1-1.5g / cm 3 , the specific surface area is greater than 15m 2 / g,D 50 With 3-8μm lithium iron phosphate as the positive electrode material, add 2% conductive graphite accounting for its weight percentage, place it in a closed container with an inert protective gas and stir at high speed, and spray N-methylpyrrolidone solvent at the same time. The total amount of solvent added is 2% of the powder weight, and the duration is 20 minutes.

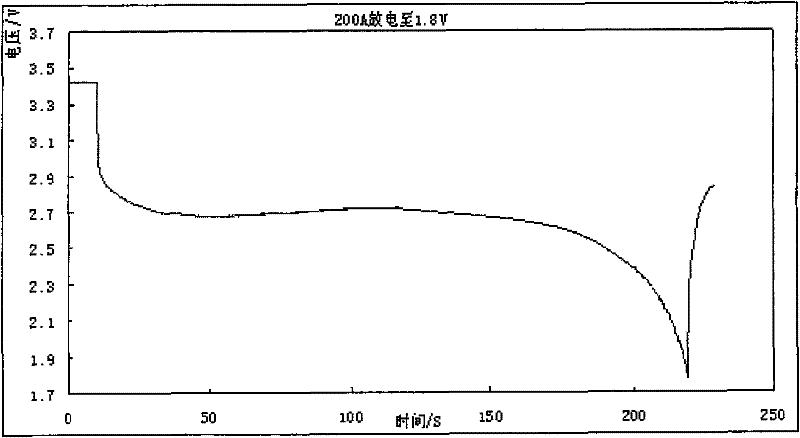

[0024] 97% by weight of the positive electrode active material, 3% of polyvinylidene fluoride, and N-methylpyrrolidone solvent accounting for 90% of the solid content are added and mixed evenly to make a positive electrode slurry, and the positive electrode slurry is coated on After being dried at a temperature of 80-100° C. on a metal aluminum foil with a thickness of 18 μm, it is rolled into a positive electrod...

Embodiment 2

[0029] Taking the manufacture of 1882130 type 10Ah square lithium iron phosphate battery as an example, the selected tap density is 1-1.5g / cm 3 , the specific surface area is greater than 15m 2 / g,D 50 With 3-8μm lithium iron phosphate as the positive electrode material, after adding 1% carbon nanotube material and 1% conductive graphite accounting for its weight percentage, it is placed in a closed container with an inert protective gas and stirred at high speed, while spraying N-methylpyrrolidone solvent, the total amount of the sprayed solvent is 3% of the powder weight, and the duration is 20 minutes.

[0030] 98% by weight of the positive electrode active material, 2% of polyvinylidene fluoride, and N-methylpyrrolidone solvent accounting for 96% of the solid content are added and mixed evenly to make a positive electrode slurry, and the positive electrode slurry is coated on After being dried at a temperature of 80-100° C. on a metal aluminum foil with a thickness of 18...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com