Silicon-containing epoxy resin composition for light-emitting diode (LED) package and preparation method thereof

A technology of LED encapsulation and silicone epoxy resin, applied in epoxy resin glue, epoxy resin coating, plastic/resin/wax insulator, etc. Excellent thermal stability and mechanical strength, meeting process and performance requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

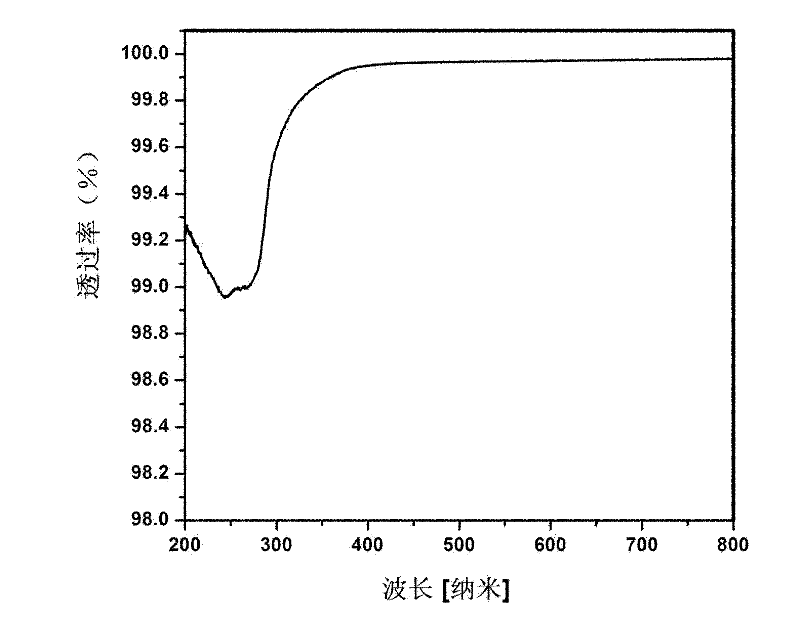

[0042] 10 grams of Epo-4, 2 grams of Unox 206, 0.5 grams of ethylene glycol, and 0.1 grams of p-methoxybenzenediazonium hexafluoroantimonate were mechanically stirred at room temperature for 30 minutes to form a uniform and transparent solution. The epoxy composition was coated on a glass slide, cured at 75°C for 30 minutes, and then heated to 100°C for 90 minutes to obtain a transparent cured product. Epoxy composition solution and product properties after curing are shown in Table 1 (light transmittance sees attached figure 1 ).

Embodiment 2

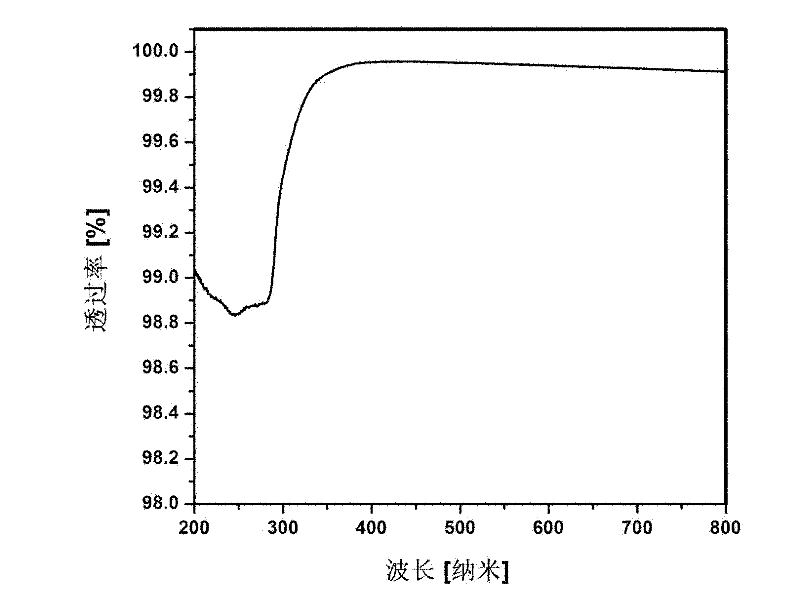

[0044] 10 grams of EPO-6, 3 grams of ERL-4221, 1 gram of diglycidyl ether, and 0.1 gram of triphenylthio-hexafluoroborate were mechanically stirred at room temperature for 30 minutes to form a uniform and transparent solution. The epoxy composition was coated on a glass slide, cured at 85°C for 30 minutes, and then gradually heated to 110°C for 100 minutes to obtain a transparent cured product. Epoxy composition solution and product properties after curing are shown in Table 1 (light transmittance sees attached figure 2 ).

Embodiment 3

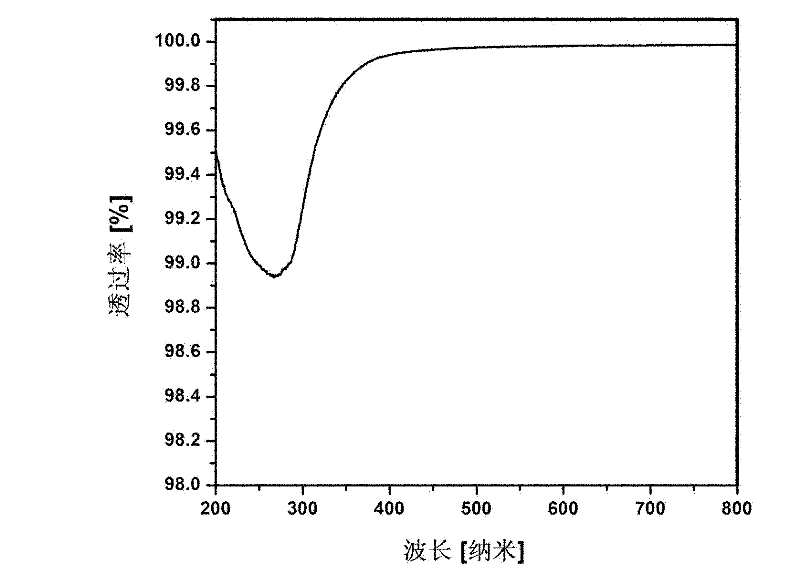

[0046] 10 grams of EPO-3, 2 milliliters of cyclohexane, 0.1 grams of triphenylsulfur hexafluoroantimonate and 0.2 grams of benzophenone were mechanically stirred at room temperature for 30 minutes to form a uniform and transparent solution. The epoxy composition was coated on a glass slide, and after the cyclohexane volatilized, the sample was cured by ultraviolet light at room temperature for 5 minutes to obtain a transparent cured product. Epoxy composition solution and product properties after curing are shown in Table 1 (light transmittance sees attached image 3 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com