Mesoporous silica particle compound carrier with controlled-release function as well as preparation method and application thereof

A technology of mesoporous silica and composite carrier, applied in chemical instruments and methods, silicon compounds, inorganic chemistry, etc., can solve the problems of unstable drying and preparation, and achieve favorable drug loading, low preparation temperature, convenient large-scale The effect of mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

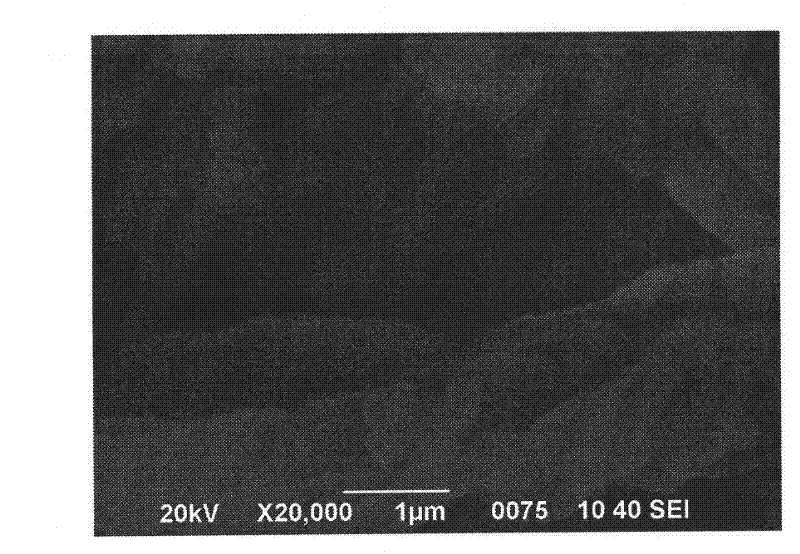

[0029] Weigh 0.15g of SBA-15 solid particles and disperse them into 100mL of water under ultrasonic conditions, then add 0.05mL of a silica colloidal solution with a mass concentration of 40%, and then ultrasonically disperse for half an hour to obtain a uniformly mixed suspension. The uniformly mixed suspension is spray-dried through a spray dryer with a maximum power of 3 kilowatts (produced by Shanghai Shunyi Experimental Equipment Co., Ltd.). The spray drying temperature is controlled at 160-250°C, and the flow rate is controlled at 150-200mL / h. The white powder obtained by drying is the mesoporous silica particle composite carrier, such as figure 1 As shown, the carrier core is short rod-shaped mesoporous silica particles with regular mesoporous pores, and the outer surface of the particles is covered with a thin layer of silica nanoparticles to modify the outer surface and pore openings of the mesoporous silica particles. Control the surface properties of mesoporous silica...

Embodiment 2

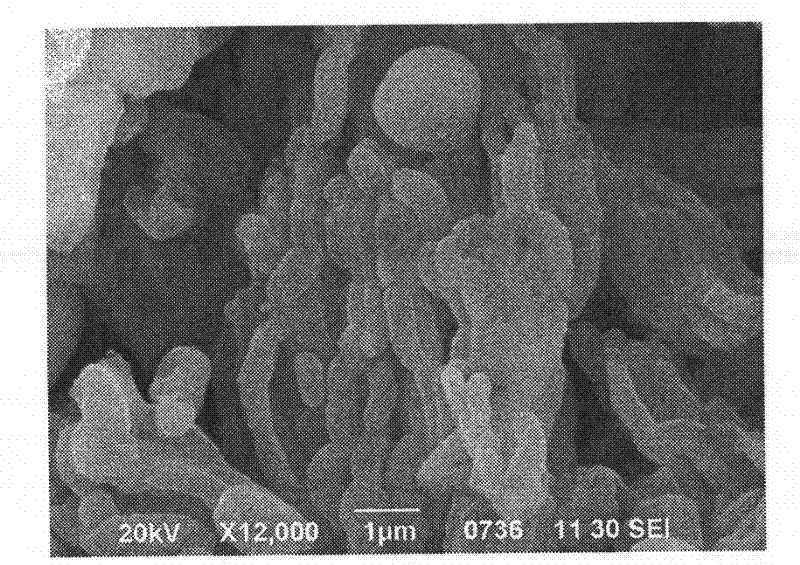

[0031] Weigh 0.15g of SBA-15 solid particles and disperse them into 100mL of water, then add 0.1mL of a 40% mass concentration of silica colloidal solution, and ultrasonically disperse for half an hour to obtain a well-mixed suspension, and then mix the well-mixed suspension The spray drying is carried out by a spray dryer with a maximum power of 3 kilowatts. The spray drying temperature is controlled at 160-250℃, and the flow rate is controlled at 150-200mL / h. The white powder obtained by drying is covered with silica nanoparticles. Thin layer of short rod-shaped mesoporous silica composite carrier, such as figure 2 Shown.

Embodiment 3

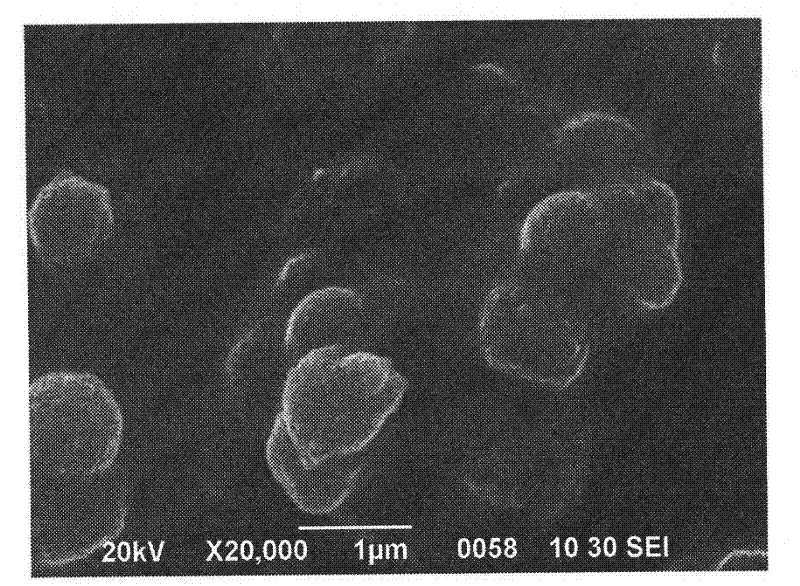

[0033] Weigh 0.1g of MCM-41 solid particles and disperse them into 50mL of water, then add 0.02mL of a 40% mass concentration of silica colloidal solution, and ultrasonically disperse for half an hour to obtain a well-mixed suspension, and then mix the well-mixed suspension The spray drying is carried out by a spray dryer with a maximum power of 3 kilowatts. The spray drying temperature is controlled at 160-250℃, and the flow rate is controlled at 150-200mL / h. The white powder obtained by drying is covered with silica nanoparticles. Thin layer of spherical mesoporous silica composite carrier, such as image 3 Shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com