Industrial production method for cyclopropyl sulfinate

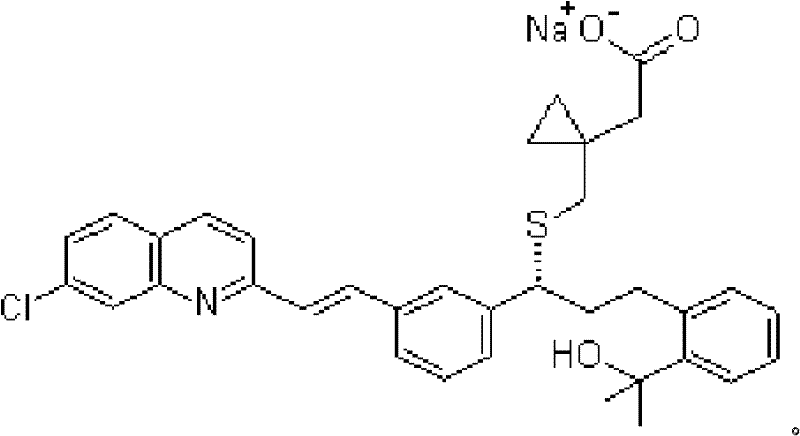

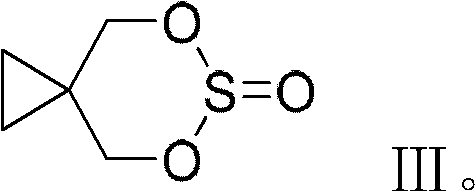

A technology of cyclopropyl sulfinate and ester compound, which is applied in the synthesis of pharmaceutical intermediates and in the field of industrial production of montelukast sodium intermediate cyclopropyl sulfinate, which can solve the problem of low yield of final product and unfavorable Industrialized production, high temperature of cyclization reaction, etc., to achieve the effect of facilitating industrialized production, solving the difficulty of product filtration, and high product yield and purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

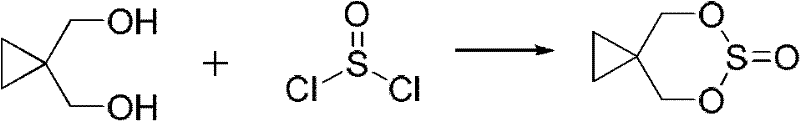

Embodiment 1

[0038] Put 100ml of toluene into the reaction bottle, then add 50g of dibromoneopentyl glycol, stir and heat up to 45°C, during the dropwise addition, keep the temperature at 45°C-55°C, and start to add 25g of thionyl chloride dropwise. During the dropwise addition, dibromoneopentyl glycol gradually dissolves, and hydrogen chloride gas is generated, and the generated hydrogen chloride gas is absorbed with water. After the dropwise addition, the temperature was controlled at 45° C. to 55° C. and kept for 3.0 hours. During the heat preservation process, samples were taken and analyzed by TLC. After the raw materials were completely reacted, the temperature was controlled below 70°C, and the solvent was recovered under reduced pressure until evaporated to dryness. After evaporating to dryness, 10 g (about 10 ml) of DMF was added to the residue to obtain 70 g of esterified compound II / DMF mixture. Wherein the developer used for TLC detection is a mixed developer of petroleum ethe...

Embodiment 2

[0043] Put 100ml of xylene into the reaction bottle, then add 50g of dibromoneopentyl glycol, stir and heat up to 50°C, during the dropwise addition, keep the temperature at 50°C to 55°C, and start to add 45g of thionyl chloride dropwise. During the dropwise addition, dibromoneopentyl glycol gradually dissolves, and hydrogen chloride gas is generated, and the hydrogen chloride gas is absorbed with water. After the dropwise addition, the temperature was controlled at 50° C. to 55° C., and the temperature was kept for 2.0 hours. During the heat preservation process, samples were taken and analyzed by TLC. After the raw materials were completely reacted, the temperature was controlled below 70°C, and the solvent was recovered under reduced pressure until evaporated to dryness. After evaporating to dryness, 10 g of formamide was added to the residue to obtain 75 g of esterified product II / formamide mixture. Wherein the developer used for TLC detection is a mixed developer of petr...

Embodiment 3

[0047] Put 150ml of n-hexane into the reaction bottle, then add 50g of dibromoneopentyl glycol, stir and heat up to 30°C, during the dropwise addition, keep the temperature at 30°C-45°C, and start to add 30g of thionyl chloride dropwise. During the dropwise addition, dibromoneopentyl glycol gradually dissolves and hydrogen chloride gas is generated, and the generated hydrogen chloride gas is absorbed with water. After the dropwise addition, the temperature was controlled at 40° C. to 45° C. and kept for 4.0 hours. During the heat preservation process, samples were taken and analyzed by TLC. After the raw materials were completely reacted, the temperature was controlled below 70°C, and the solvent was recovered under reduced pressure until evaporated to dryness. After evaporating to dryness, 10 g (about 10 ml) of DMF was added to the residue to obtain esterified compound II / DMF mixture 75.

[0048] Put 150ml of DMF and 13g of zinc powder into another reaction bottle, stir, hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com