Sustained control release preparation of nano porous active carbon-carrying agricultural antibiotic and preparation method thereof

An agricultural antibiotic and nanoporous technology, applied in botany equipment and methods, chemicals for biological control, biocides, etc., can solve problems such as unsatisfactory control effect, poor stability of agricultural antibiotics, harsh storage conditions, etc., to achieve Improve solubility, increase utilization, and reduce pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

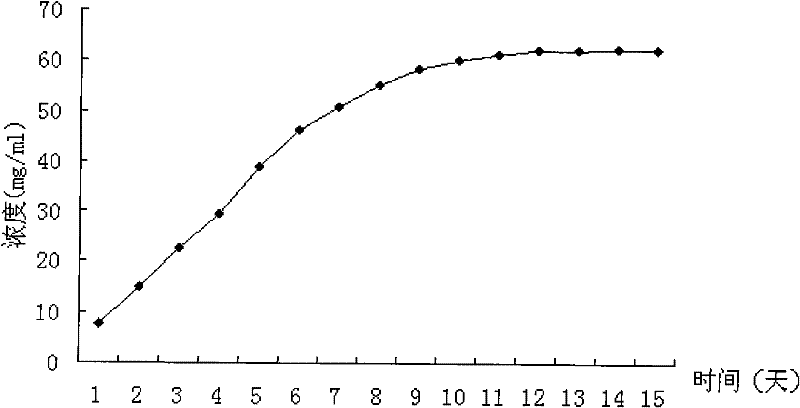

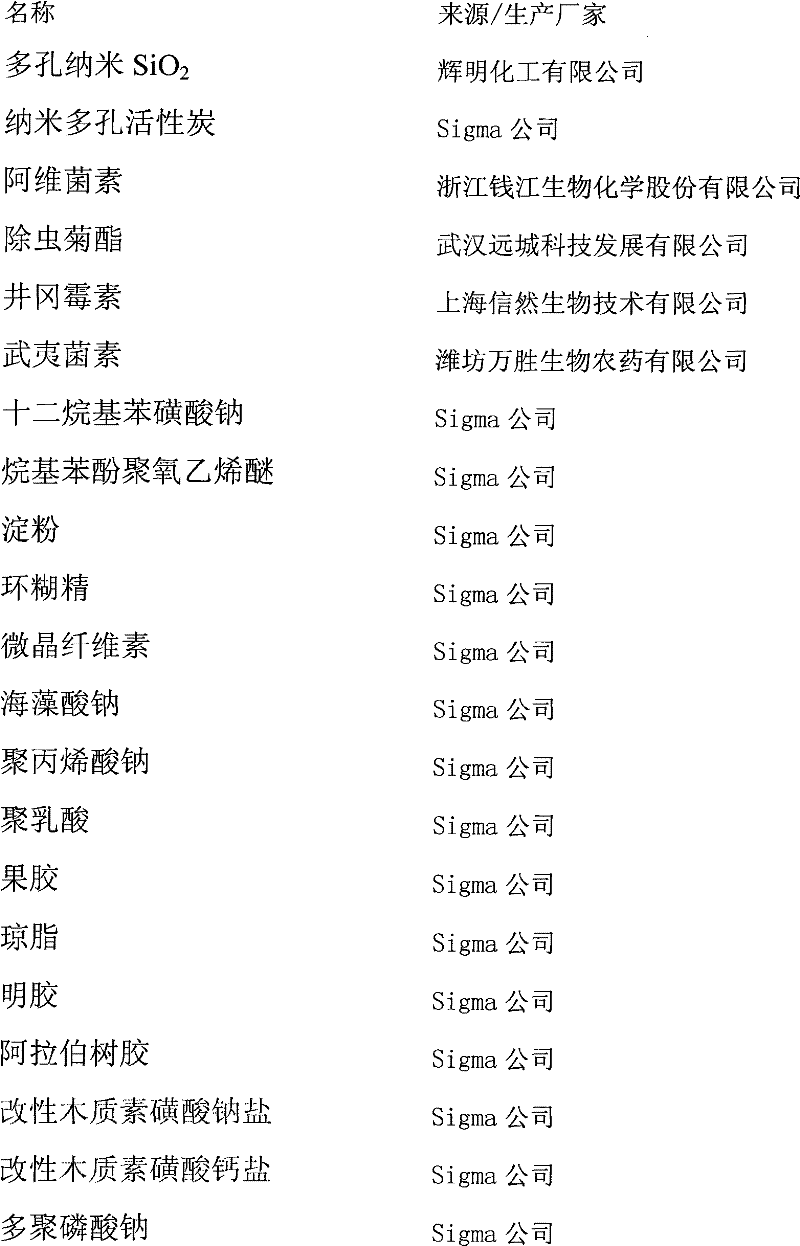

[0045] This example is to prepare a preparation containing 50% abamectin loaded on nanoporous activated carbon

[0046] Add 1.0kg of Abamectin original drug into the mixing tank, add 100L of acetone, fully dissolve, add 0.8kg of porous activated carbon [pore size between 100nm-500nm], fully absorb for 24 hours, then transfer to a rotary evaporator. Evaporate acetone at 50°C and 0.02MPa to recrystallize the abamectin solution. After the recrystallization is finished, the abamectin-activated carbon sustained and controlled release granules are obtained. Then add 0.01kg microcrystalline cellulose, 0.01kg sodium alginate, 0.02kg sodium dodecylbenzenesulfonate, 0.01kg sodium polyphosphate, 0.01kg dimethyl sulfoxide, 0.01kg dioctyl sulfosuccinate Sodium salt, 0.13kg urea, after mixing evenly, place in the ball mill and grind for 3h, take out the mixture, you can get nanoporous activated carbon loaded powder containing 50% abamectin. Take out the powder, place it in a tablet press ...

Embodiment 2

[0057] This experiment is to prepare a preparation containing 60% pyrethrins loaded on porous activated carbon

[0058] Add 1.2kg of pyrethrin technical material into the mixing tank, add 100L of acetone, fully dissolve, add 0.6kg of nanoporous activated carbon [pore size between 100nm and 500nm], fully absorb for 24 hours, then transfer to a rotary evaporator. Evaporate acetone at 50°C and 0.02MPa to recrystallize the avermectin solution. After the recrystallization is finished, the pyrethrin-activated carbon sustained and controlled release granules are obtained. Then add 0.01kg microcrystalline cellulose, 0.01kg sodium alginate, 0.02kg sodium dodecylbenzenesulfonate, 0.01kg sodium polyphosphate, 0.01kg dimethyl sulfoxide, 0.01kg dioctylsulfosuccinate Ester sodium salt, 0.13kg urea, mixed evenly, placed in a ball mill and ground for 3 hours, and the mixture was taken out to obtain a nanoporous activated carbon-loaded powder containing 60% pyrethrins. Take out the powder, p...

Embodiment 3

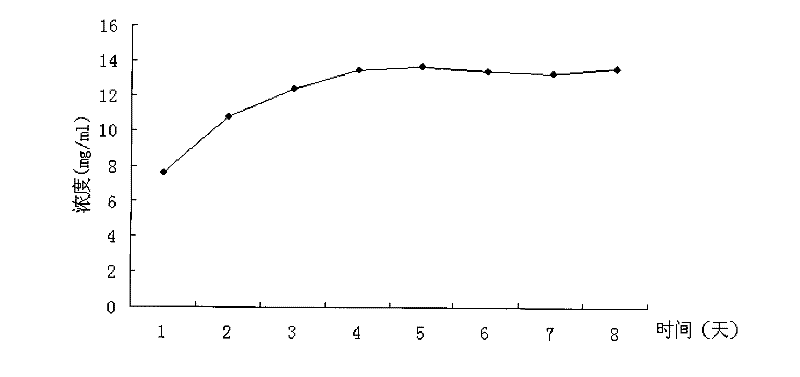

[0060] This example is to prepare a preparation containing 80% Jinggangmycin loaded on porous nanoporous activated carbon

[0061] Dissolve 1.6kg of Jinggangmycin in 5L of water, add 0.3kg of nanoporous activated carbon [pore size between 100nm and 500nm] after fully dissolved, fully absorb for 24 hours, then transfer to a rotary evaporator. Evaporate acetone at 50°C and 0.02MPa to recrystallize the avermectin solution. After recrystallization, Jinggangmycin-activated carbon slow-release granules are obtained. Then add 0.005kg starch, 0.005kg sodium alginate, 0.005kg sodium dodecylbenzenesulfonate, 0.005kg sodium polyphosphate, 0.005kg dimethyl sulfoxide, 0.005kg dioctyl sulfosuccinate sodium salt , 0.07kg of urea, after mixing evenly, place in a ball mill and grind for 3h, take out the mixture, and get nanoporous activated carbon loaded powder containing 80% Jinggangmycin. Take out the powder, place it in a tablet press or granulator, and press it into a sheet or granule ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com