3 mu m luminous rare earth ion doped fluorophosphates laser glass and preparation method thereof

A technology of fluorophosphate and laser glass, which is applied in the field of fluorophosphate glass and its preparation, can solve the problems that fluorophosphate glass is rarely reported, and achieve the effect of excellent physical and chemical properties and high infrared transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Composition is as shown in 1# in table 1, and concrete preparation process is as follows:

[0025] According to the mole percentage of the 1# glass composition in Table 1, calculate the weight of the corresponding components, weigh the raw materials and mix them evenly; put the mixture into a platinum crucible and melt it in a silicon carbide rod electric furnace at 1050°C until completely melted After clarifying for 15 minutes, pour the molten glass into the preheated mold; quickly move the glass into a muffle furnace that has been heated to 420°C, keep it warm for 3 hours, then lower it to room temperature at a rate of 10°C / hour, and cool it completely Then remove the glass sample.

[0026] The test results for this glass are as follows:

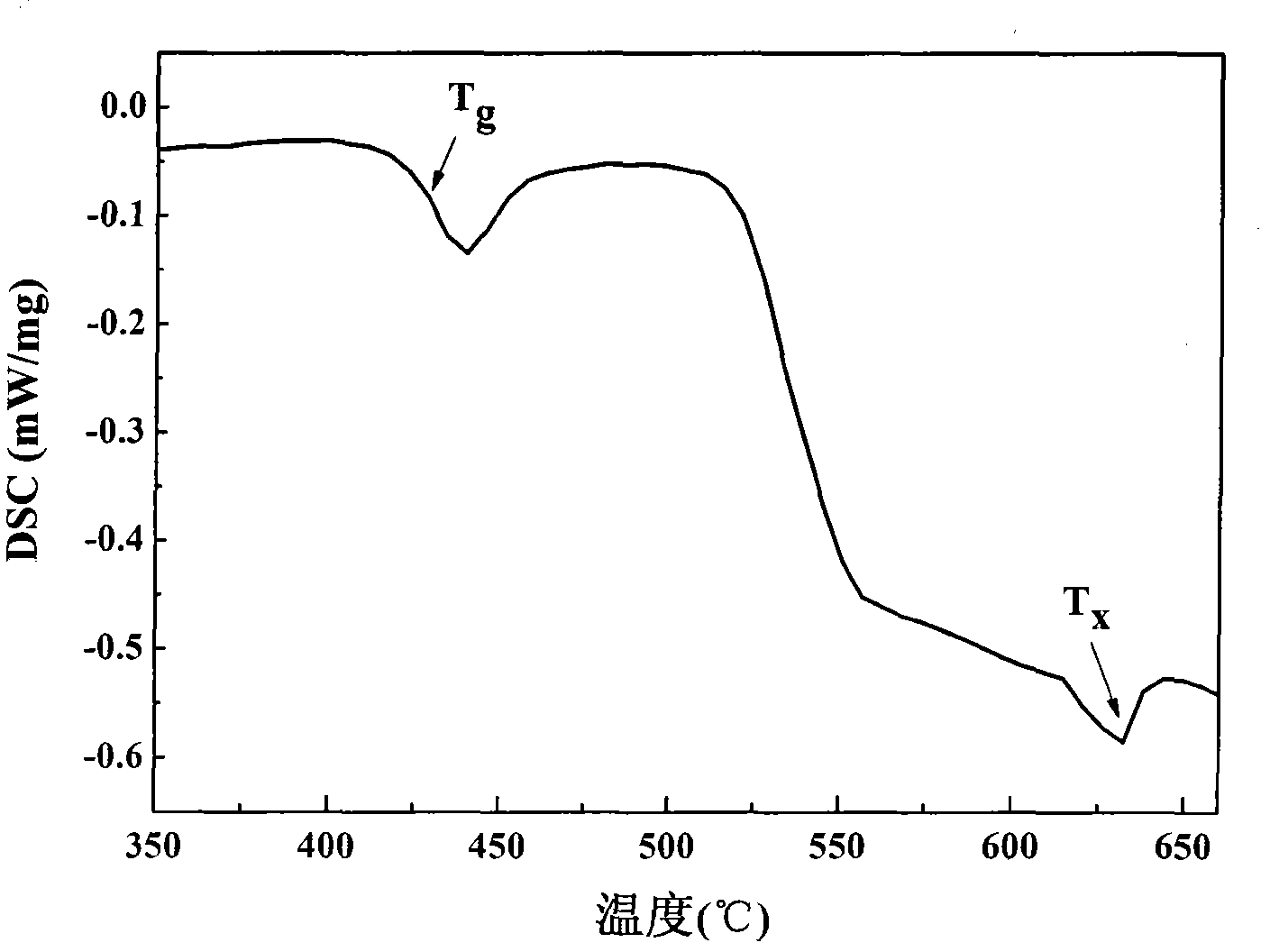

[0027] Take a small sample after annealing, grind it into a fine powder with an agate mortar, and conduct a differential thermal analysis test. The differential thermal curve of the 3 μm light-emitting rare earth ion-doped fluorop...

Embodiment 2

[0030] Composition is as shown in 2# in table 1, and concrete preparation process is as follows:

[0031] According to the mole percentage of the 2# glass composition in Table 1, calculate the weight of the corresponding components, weigh the raw materials and mix them evenly; put the mixture into a platinum crucible and melt it in a silicon carbide rod electric furnace at 1050 °C, after it is completely melted After clarifying for 13 minutes, pour the molten glass into a preheated mold; quickly move the glass into a muffle furnace that has been heated to 430°C, keep it warm for 3.5 hours, then lower it to room temperature at a rate of 10°C / hour, and cool it completely Remove the glass sample.

[0032] The test results for this glass are as follows:

[0033] Take a small sample after annealing, grind it into a fine powder with an agate mortar, and conduct a differential thermal analysis test.

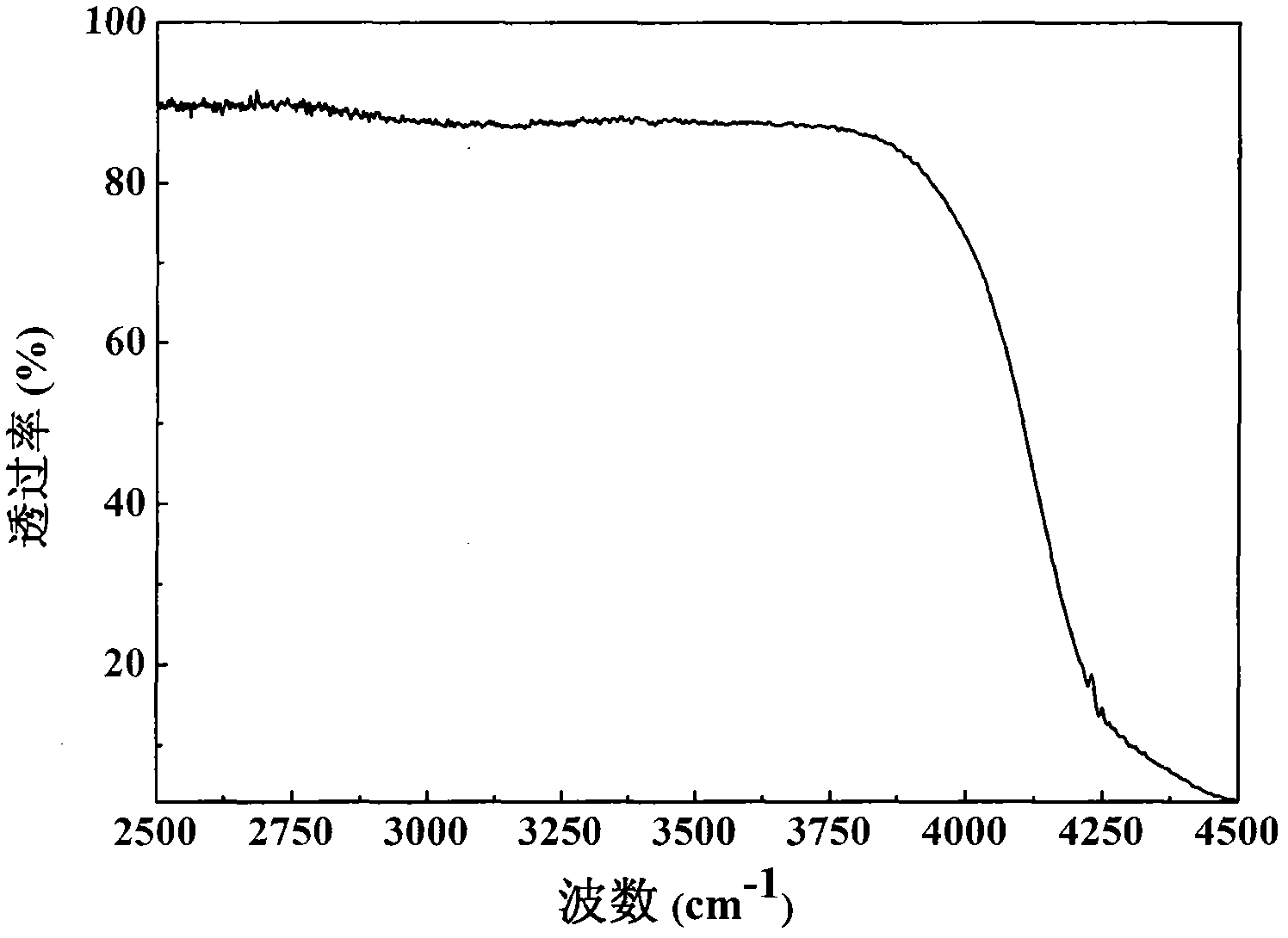

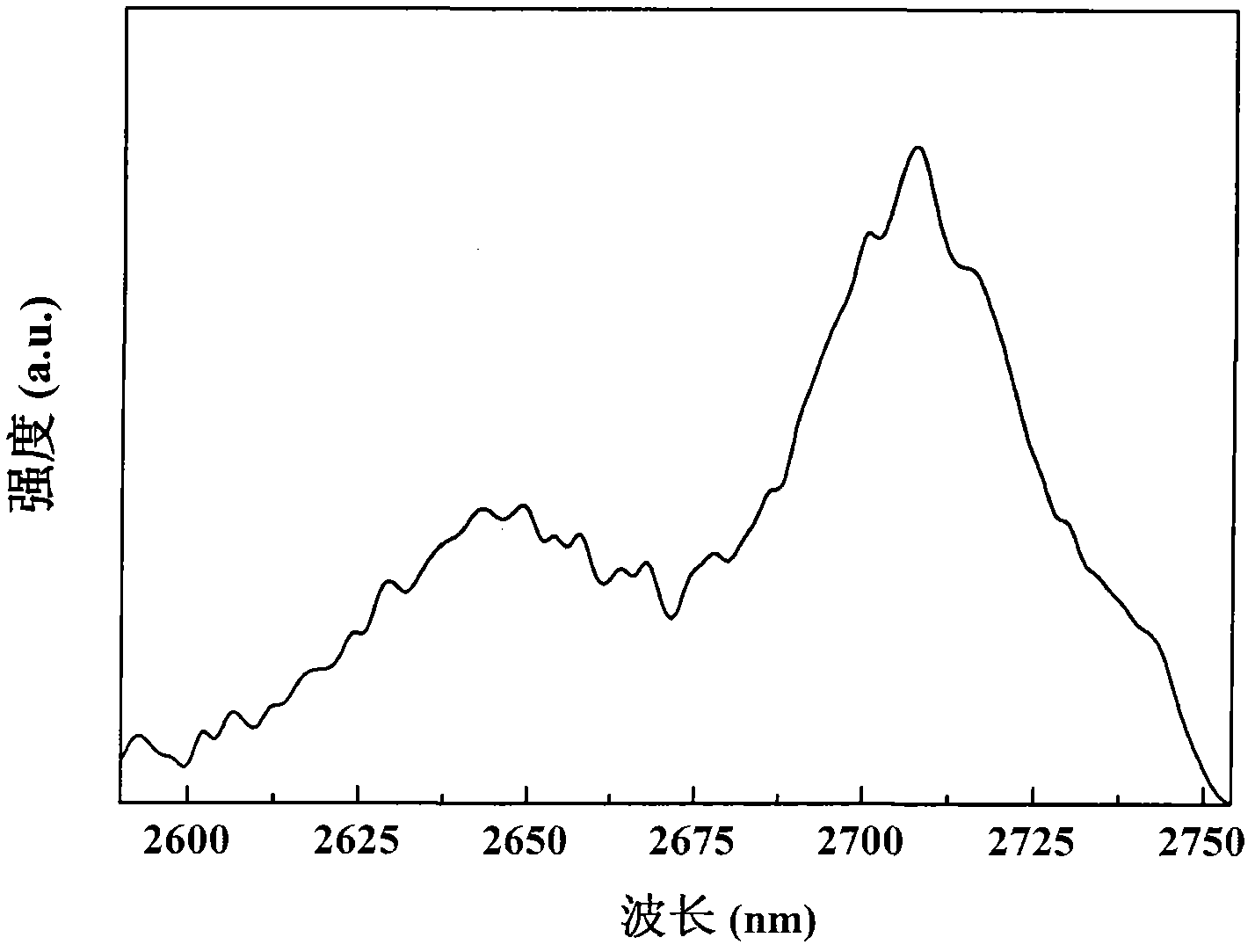

[0034] The annealed sample was processed into a 10×20×1.0 mm glass plate and poli...

Embodiment 3

[0036] Composition is as shown in 3# in table 1, and concrete preparation process is as follows:

[0037] According to the mole percentage of the 3# glass composition in Table 1, calculate the corresponding weight percentage of each composition, weigh each raw material and mix evenly; put the mixture into a platinum crucible and melt it in a silicon carbide rod electric furnace at 1080°C until completely melted After clarifying for 15 minutes, pour the molten glass into the preheated mold; quickly move the glass into a muffle furnace that has been heated to 440°C, keep it warm for 4 hours, then lower it to room temperature at a rate of 10°C / hour, and cool completely Then remove the glass sample.

[0038] The test results for this glass are as follows:

[0039] Take a small sample after annealing, grind it into a fine powder with an agate mortar, and conduct a differential thermal analysis test.

[0040] The annealed sample was processed into a 10×20×1.0 mm glass plate and po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com