Bi-component polyurethane adhesive as well as preparation method and application thereof

A two-component polyurethane and adhesive technology, which is applied in the field of sealants, can solve the problems that the focal spot of installation and detection cannot meet the requirements, it is difficult to adjust the relative position of the lens and the mirror case, and the temperature changes greatly between day and night.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0089] A two-component polyurethane adhesive, the adhesive includes A component and B component, and after the A component and the B component are uniformly mixed in a mass ratio of 1.2:1, the two-component polyurethane adhesive is obtained;

[0090] A and B components are composed of the following raw materials in mass percentage:

[0091] A component:

[0092] Polyurethane prepolymer 30%

[0093] Didecyl phthalate 30%

[0094] Talc and ceramics 40%;

[0095] Wherein, the polyurethane prepolymer in A component is made up of the raw material of following mass percent:

[0096] Didecyl phthalate 28%

[0097] Two-functional polypropylene ether polyol 30%

[0098] Trifunctional Polypropylene Ether Polyol 30%

[0099] Hexamethylene diisocyanate 12%;

[0100] B component:

[0101] Two-functional polypropylene ether polyol 20%

[0103] Didecyl phthalate 15%

[0104] Fumed silica 2.1%

[0105] Zinc isooctanoate 1%

[0106] UV absorber UV-327...

Embodiment 2

[0116] A preparation method of the two-component polyurethane adhesive of embodiment 1, comprises the following steps:

[0117] (1) Preparation of component A: According to the formula, polyurethane prepolymer, didecyl phthalate and talcum powder are mixed evenly to prepare component A;

[0118] Among them, the preparation of polyurethane prepolymer in component A: add didecyl phthalate, difunctional polypropylene ether polyol, trifunctional polypropylene ether polyol and hexamethylene diisocyanate to the synthetic In the reaction kettle, under the conditions of a temperature of 110°C and a vacuum degree greater than 0.095Mpa, water was removed for 3 hours, and the water content of the liquid material was measured to be less than 300ppm, and then the temperature was lowered to 65°C and reacted for 5 hours to obtain the polyurethane prepolymerized body;

[0119] (2) Preparation of component B: According to the formula quantity, bifunctional polypropylene ether polyol with a mo...

Embodiment 3

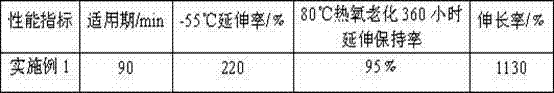

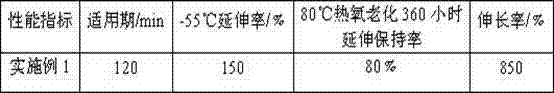

[0122] The two-component polyurethane adhesive in Example 1 was applied to the bonding between the concentrating solar mirror shell and the lens. The two-component polyurethane adhesive used in Example 1 can be used for the bonding between the large-area concentrating solar mirror shell and the lens, and has the characteristics of long pot life, good flexibility, and good thermal and oxygen aging resistance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com