Resin-cast desulphurization nozzle and manufacturing method thereof

A technology of resin casting and desulfurization nozzles, which is applied in separation methods, chemical instruments and methods, and separation of dispersed particles. It can solve problems such as poor wear resistance, poor shock resistance, and short service life, and achieve simple and practical processes and strong corrosion resistance. , The effect of low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

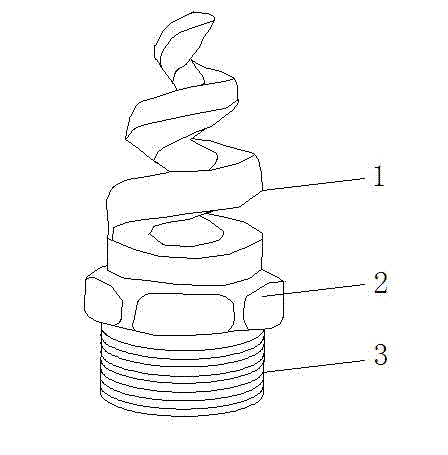

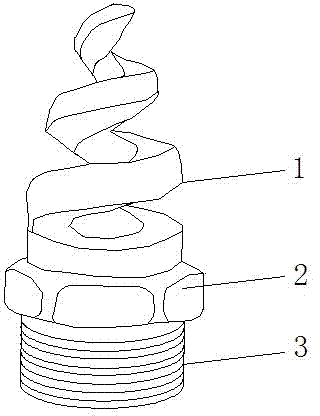

[0021] Refer to attached figure 1 Enumerate embodiment and further illustrate the present invention:

[0022] from figure 1 It can be seen from the figure that the resin pouring desulfurization nozzle is composed of a conical spiral nozzle (1), a nut (2) and a threaded interface (3). One end of the nut (2) is connected to the conical spiral nozzle (1), and the other end is connected to the screw thread The interfaces (3) are connected, and the three are connected into one body along the same axis, and the middle is hollow.

[0023] The manufacturing method of resin casting desulfurization nozzle is as follows:

[0024] (1) Apply release agent: Apply release agent to the outer surface of the inner membrane and the inner surface of the outer membrane;

[0025] (2) Ingredients: ingredients by weight percentage: resin 76%, color paste 2%, curing agent 1%, accelerator 0.5%, wear-resistant filler 19% and glass fiber 1.5%;

[0026] (3) Mixing material: Stir the resin, color paste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com