Preparation method of carbon film obtained by self assembly of graphene oxide or its derivatives

A technology of derivatives and graphene, which is applied in the field of preparation of highly ordered carbon films, can solve problems such as poor bonding between carbon films and substrates, difficulty in controlling the thickness of carbon films, and complicated preparation processes, achieving simple process, good mechanical properties, The effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

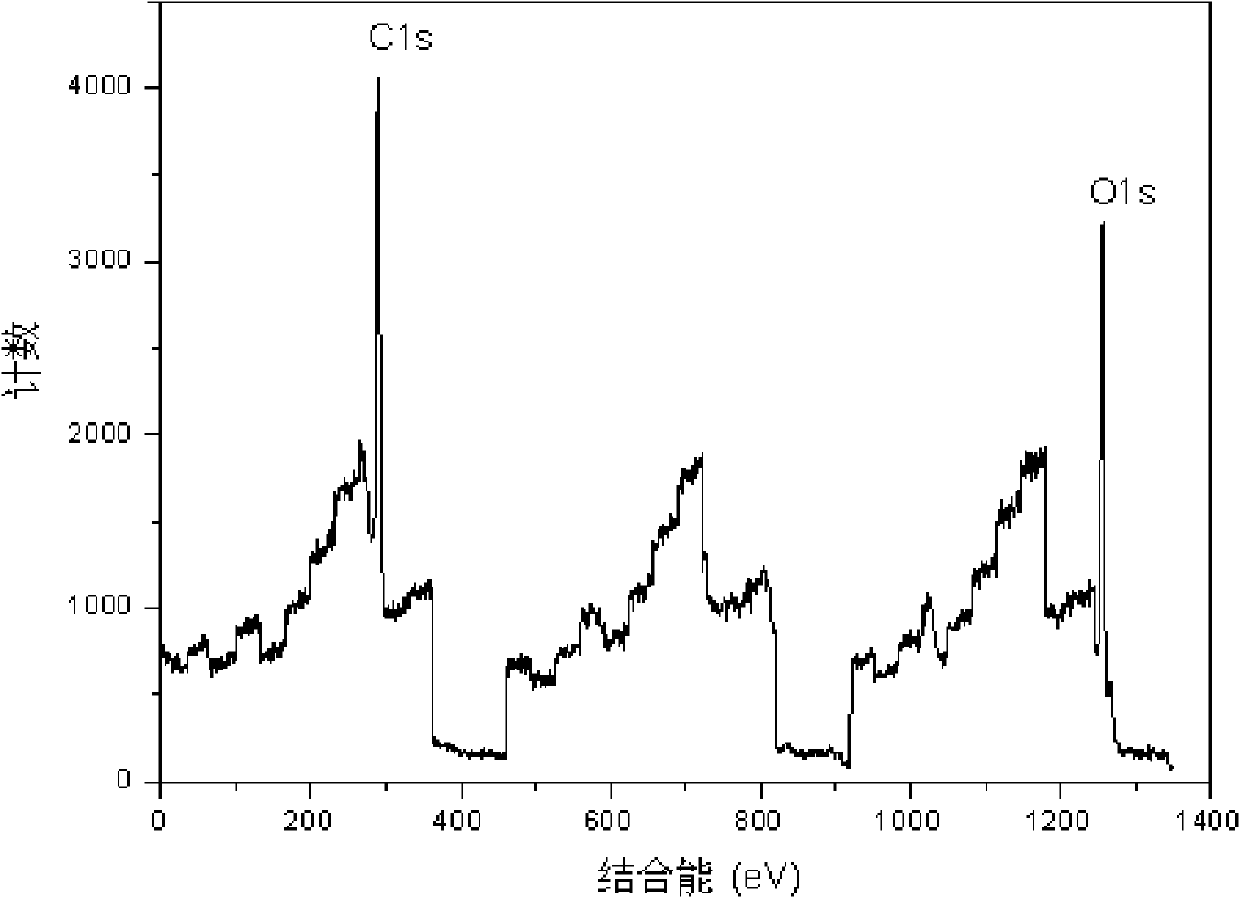

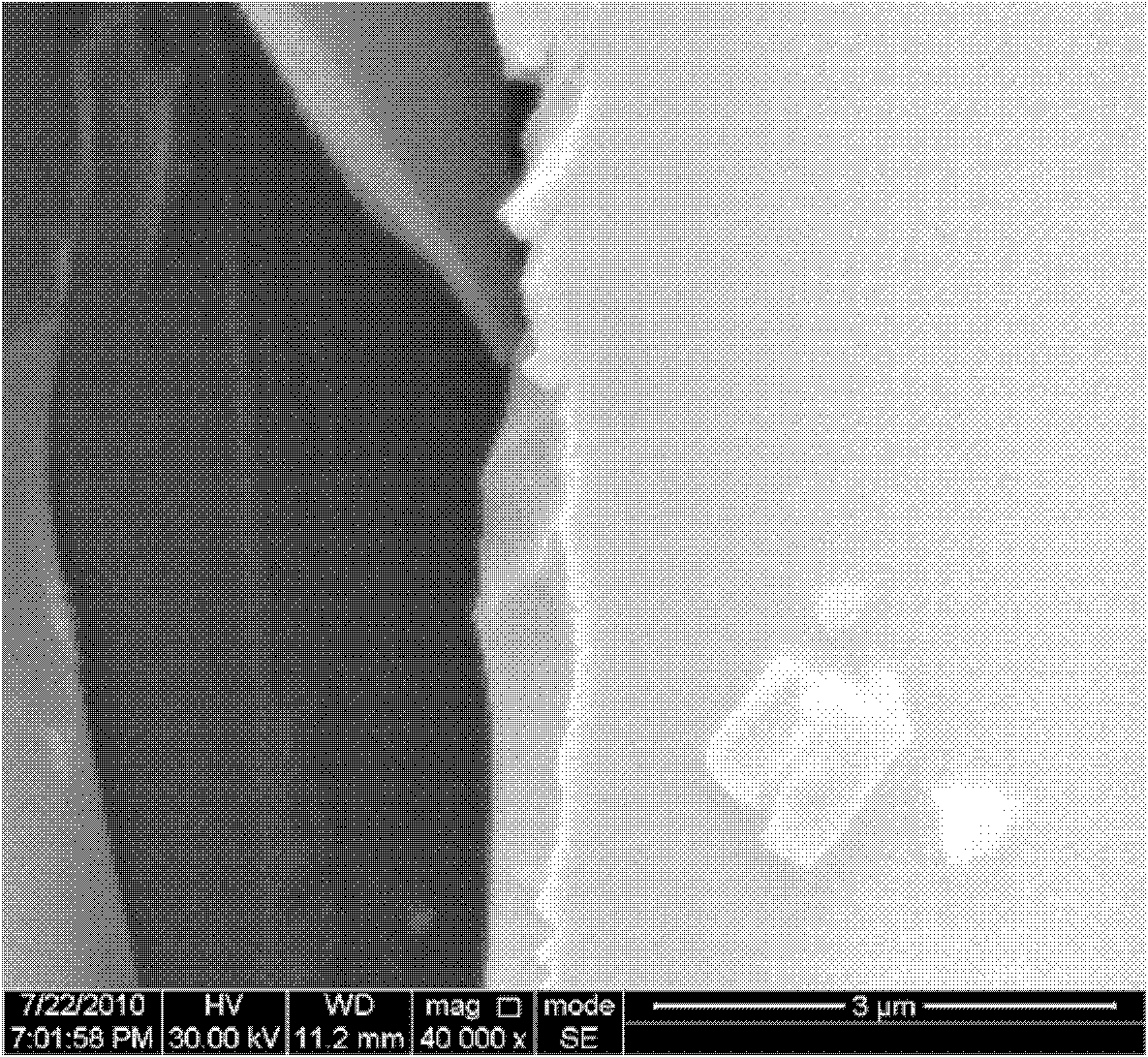

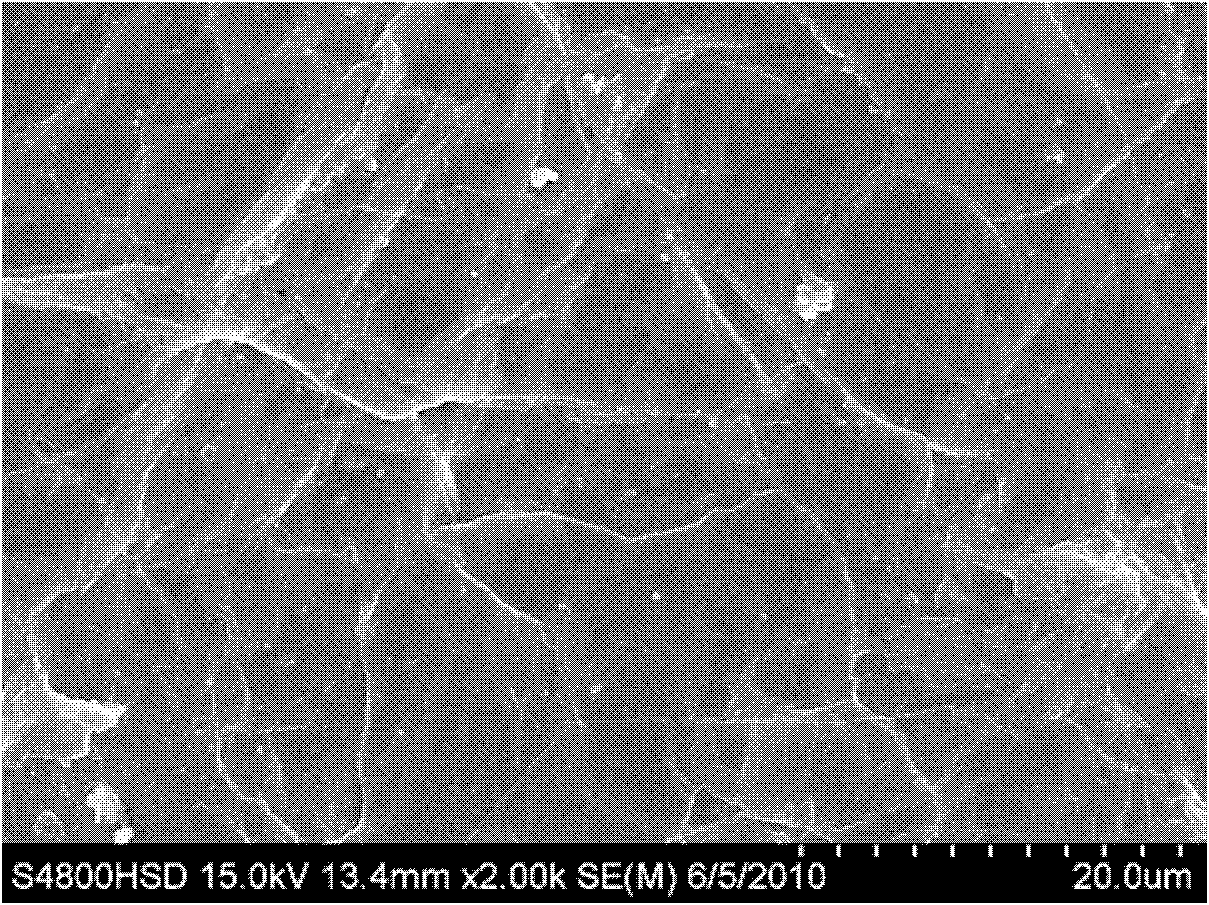

[0025] Specific Embodiment 1: This embodiment is a carbon film obtained by self-assembly of graphene oxide or its derivatives, which is obtained by self-assembly of graphene oxide or its derivatives as a raw material. The electrical conductivity of the carbon film is 1 to 10 3 S / cm, wherein the graphene oxide derivatives are prepared by modifying graphene oxide with organic amines or organic alcohols.

[0026] The surface of the carbon film in this embodiment is flat and smooth, has good light transmission performance and good mechanical properties, the modulus is 80-120GPa, and the hardness is 7-9GPa; the carbon film is oriented and ordered along the surface of the substrate, and the thickness is 50nm- 2 μm.

[0027] The graphene oxide raw material in this embodiment is a commercially available product, or is prepared by an existing published chemical oxidation method.

specific Embodiment approach 2

[0028] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the conductivity of the carbon film is 1×10 2 ~9×10 2 S / cm. Other parameters are the same as in the first embodiment.

specific Embodiment approach 3

[0029] Specific embodiment three: the difference between this embodiment and specific embodiment one is that the electrical conductivity of the carbon film is 6×10 2 S / cm. Other parameters are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com