Method for synthesis of glutathione in vitro

A glutathione and in vitro synthesis technology, applied in the direction of fermentation, etc., can solve the problems of insufficient stability of acetyl phosphate, unfavorable industrial scale-up, mass transfer obstacles, etc., and achieve the effect of eliminating mass transfer obstacles, reducing costs, and improving conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

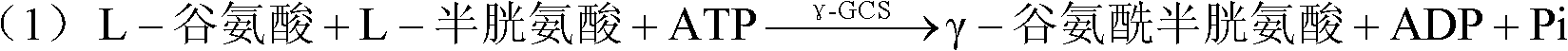

[0025]The preparation methods of the three enzymes adopt techniques well known to those skilled in the art; for example, Escherichia coli or Saccharomyces cerevisiae with high glutathione synthesis ability are used as host bacteria to construct genetically engineered recombinant bacteria to express and prepare glutathione. Three enzymes for peptide synthesis reactions. In the embodiment of the present invention, the gshA, gshB and ppk genes encoding γ-glutamylcysteine synthetase, glutathione synthetase and polyphosphate kinase were respectively cloned using E.coli BL21 (D3) as the starting bacterium , and after homologous expression in E.coli BL21(D3) through the pET-28a vector, the crude enzyme solution was extracted by sonication. The amount of the three enzymes added in the synthesis reaction was calibrated by Coomassie brilliant blue protein detection method.

[0026] Second, the detection method of glutathione concentration:

[0027] The content of intracellular gluta...

Embodiment 1

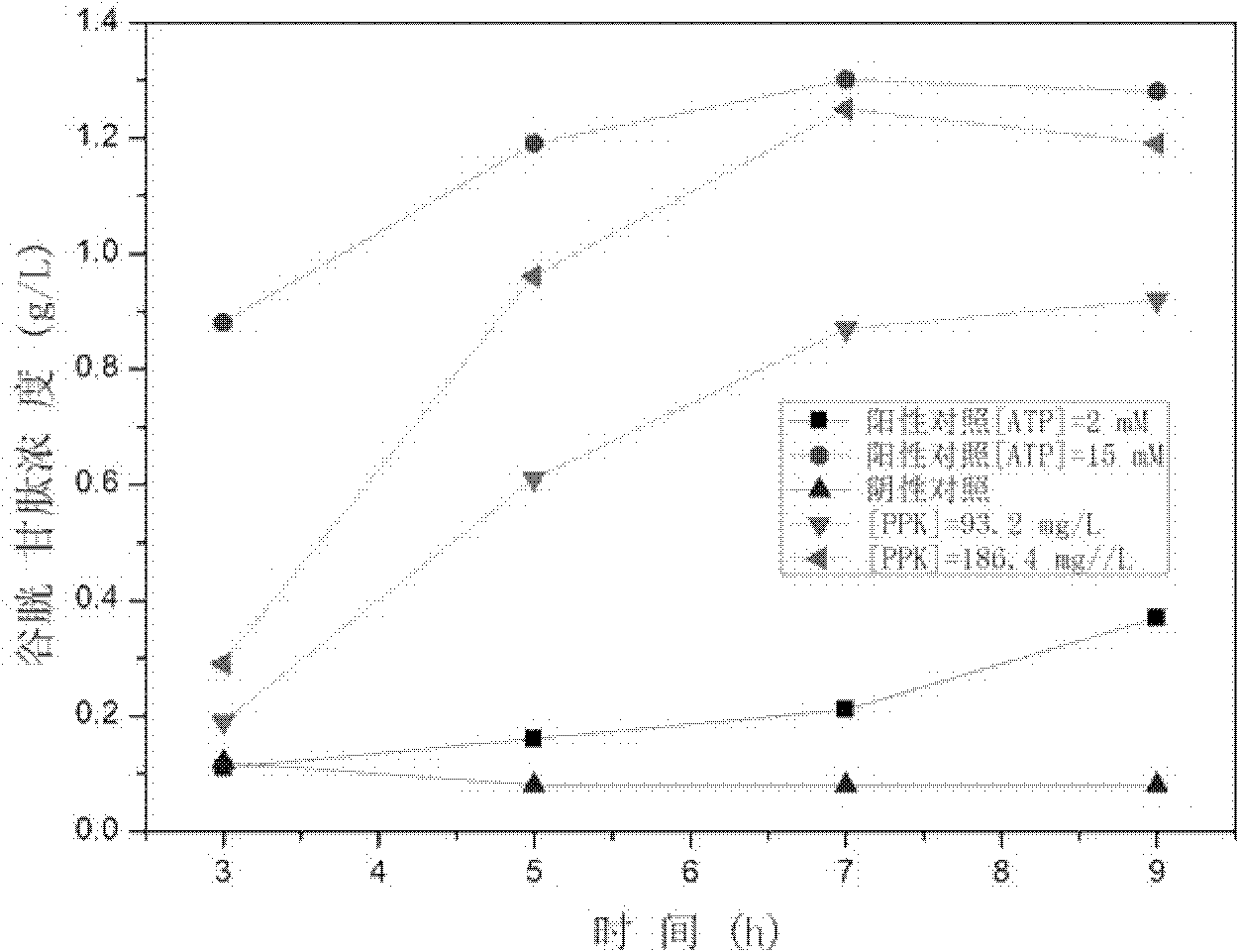

[0031] Prepare 5mM reaction substrate solution, including: 0.1M Tris-Cl, 5mM cysteine, 7.5mM glycine, 7.5mM glutamic acid, 10mM ADPNa 2 , 100mM (NaPO 3 )n, 20mM MgCl 2 ;Add 92.6mg / L of γ-glutamylcysteine synthetase and 94.8mg / L of glutathione synthase, and 93.2mg / L of polyphosphokinase, react at 37°C for 3h, 5h, 7h Take 0.5mL samples and analyze the content of glutathione with the alloxan method at 9 hours, the results are shown in figure 1 .

Embodiment 2

[0033] The rest of the conditions for synthesizing glutathione are the same as in Example 1; only the amount of polyphosphokinase added is 186.4 mg / L. See the test results figure 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com