Synthesis method of alkaline earth metal vanadate micro/nano material by utilizing microwave radiation

A technology of alkaline earth metal salts and microwave radiation method, applied in nanotechnology, chemical instruments and methods, chemical/physical/physicochemical processes of energy application, etc., can solve the problem of restricting the vigorous development of alkaline earth metal vanadate materials and the growth of dominant directions Difficulty, fast material nucleation speed and other problems, to achieve the effect of adjustable product micro-morphology, fast and gentle reaction, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1: Preparation of calcium vanadate nanoparticles

[0030] At room temperature, prepare an aqueous solution of calcium nitrate with a molar concentration of 0.00125 mol / L; weigh the ammonium metavanadate solid so that the molar number is twice that of calcium nitrate, add distilled water at 60-75°C, and stir until metavanadic acid The ammonium was completely dissolved, and the obtained homogeneous solution was slowly added dropwise to the calcium nitrate aqueous solution, kept at a constant temperature of 60°C, and continued to stir vigorously for 15 minutes; the above-mentioned reaction raw material mixture was poured into a round-bottomed flask, and placed in a microwave radiation reactor for 30 minutes Minutes, the prepared material after the reaction is calcium vanadate micro / nano material. The product was detected by scanning electron microscopy (SEM) and showed that ( figure 1 ), its main shape is nanoparticles with good dispersion, its microstructure i...

Embodiment 2

[0031] Embodiment 2: Preparation of calcium vanadate nanoparticles and nanosheet hybrid structure

[0032] At room temperature, prepare a calcium nitrate aqueous solution with a molar concentration of 0.0025mol / L; weigh the ammonium metavanadate solid so that the molar number is twice that of calcium nitrate, add distilled water at 60-75°C, and stir until the metavanadic acid The ammonium was completely dissolved, and the obtained homogeneous solution was slowly added dropwise to the calcium nitrate aqueous solution, kept at a constant temperature of 60°C, and continued to stir vigorously for 15 minutes; the above-mentioned reaction raw material mixture was poured into a round-bottomed flask, and placed in a microwave radiation reactor for 30 minutes Minutes, the prepared material after the reaction is calcium vanadate micro / nano material. The SEM test of the product ( figure 2 ) shows that the main morphology is a mixed structure of nanoparticles and angular nanosheets; amo...

Embodiment 3

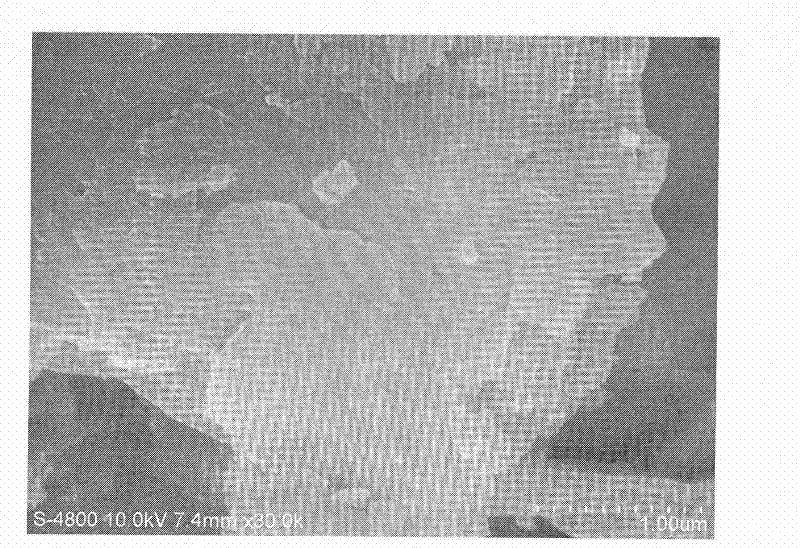

[0033] Embodiment 3: the preparation of calcium vanadate ultrathin nanosheet

[0034] At room temperature, prepare an aqueous solution of calcium nitrate with a molar concentration of 0.0050 mol / L; weigh the ammonium metavanadate solid so that its molar number is twice that of calcium nitrate, add distilled water at 60-75°C, and stir until metavanadic acid The ammonium is completely dissolved, and the obtained homogeneous solution is slowly added dropwise to the calcium nitrate aqueous solution, kept at a constant temperature of 60°C, and continued to stir vigorously for 15 minutes; the above-mentioned reaction raw material mixture is poured into a round-bottomed flask, and placed in a microwave radiation reactor for 30 minutes. Minutes, the prepared material after the reaction is calcium vanadate micro-nano material. Product SEM test ( image 3) shows that: the sample is an ultra-thin nanosheet structure, the surface of the sheet product is smooth, and there is no other coex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com