Method for producing fiber prefabricated rod

An optical fiber preform and a manufacturing method technology, which are applied in the directions of manufacturing tools, glass manufacturing equipment, glass fiber products, etc., can solve the problems of unguaranteed optical fiber performance, high manufacturing cost, low fluorine deposition efficiency, etc., and achieve good application prospects. and economic and social benefits, improving bending resistance, and improving deposition efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

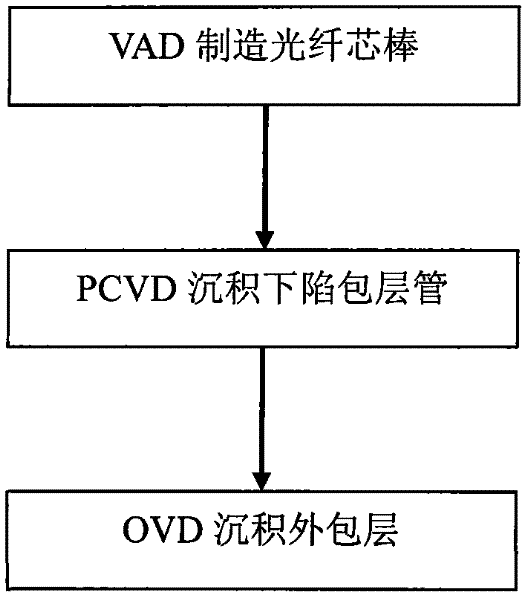

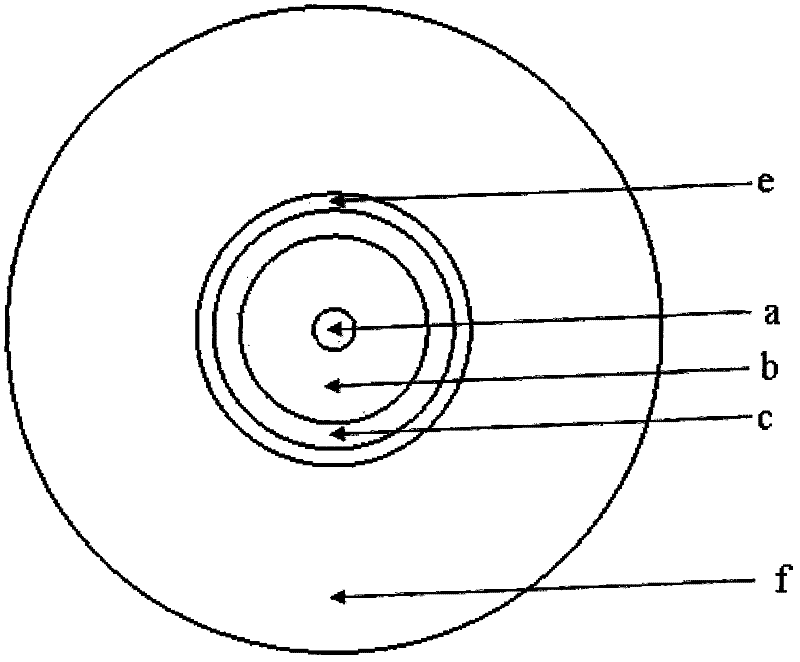

[0056] A target rod with a diameter of 70 mm is placed on a VAD deposition lathe, and a mixed gas of silicon tetrachloride, germanium tetrachloride and high-purity oxygen is introduced to form a germanium-doped quartz glass core layer at a high temperature in an oxygen-hydrogen flame (see figure 2 part a in ) and partial cladding (see figure 2 b part in), the total flow rate of the mixed gas is 19500ml / min, and the deposition rate of the core rod is 20.5g / min to form an optical fiber core rod. The ratio of the cladding diameter to the core diameter of the core rod is 3.2, and the core layer part and The relative refractive index difference of pure quartz glass is 0.35%.

[0057] A pure quartz glass substrate tube with an outer diameter of 70 mm and an inner diameter of 65 mm was placed on a PCVD deposition lathe, and silicon tetrachloride, C 2 f 6 Mixed gas with high-purity oxygen, the total flow rate of the mixed gas is 10000ml / min, under the action of 15.2kW microwave, a...

Embodiment 2

[0064] A target rod with a diameter of 80mm is placed on a VAD deposition lathe, and a mixed gas of silicon tetrachloride, germanium tetrachloride and high-purity oxygen is introduced to form a germanium-doped quartz glass core layer at a high temperature in an oxygen-hydrogen flame (see figure 2 part a in ) and partial cladding (see figure 2 Part b of the above), the total flow rate of the mixed gas is 21000ml / min, the deposition rate of the optical fiber core rod is 25g / min, forming an optical fiber core rod, the ratio of the cladding diameter to the core diameter is 4.6, the core layer part and pure silica The relative refractive index difference of glass is 0.39%.

[0065] A pure quartz glass substrate tube with an outer diameter of 70 mm and an inner diameter of 65 mm was placed on a PCVD deposition lathe, and silicon tetrachloride, C 2 f 6 Mixed gas with high-purity oxygen, the total flow rate of the mixed gas is 12000ml / min, under the action of 18.5kW microwave, a f...

Embodiment 3

[0071] A target rod with a diameter of 70 mm is placed on a VAD deposition lathe, and a mixed gas of silicon tetrachloride, germanium tetrachloride and high-purity oxygen is introduced to form a germanium-doped quartz glass core layer at a high temperature in an oxygen-hydrogen flame (see figure 2 part a in ) and partial cladding (see figure 2 Part b of the above), the total flow rate of the mixed gas is 20000ml / min, the deposition rate of the fiber core rod is 22g / min, and the fiber core rod is formed, the ratio of the cladding diameter to the core diameter is 4.2, and the core part is mixed with pure silica The relative refractive index difference of glass is 0.37%.

[0072] A pure quartz glass substrate tube with an outer diameter of 70 mm and an inner diameter of 65 mm was placed on a PCVD deposition lathe, and silicon tetrachloride, C 2 f 6 Mixed gas with high-purity oxygen, the total flow rate of the mixed gas is 11000ml / min, under the action of 16.5kW microwave, a flu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com