Infrared-radiation-assisted high-voltage static spray device with coaxial spinning nozzle and application thereof

A technology of high-voltage electrostatic spraying and coaxial spinning, which is applied in the fields of filament/thread forming, textile and papermaking, fiber treatment, etc. It can solve the problems such as the complexity of high-voltage electrostatic spraying devices and the increasing difficulty of spraying process adjustment and control, and achieve The effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

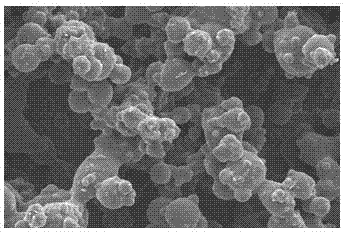

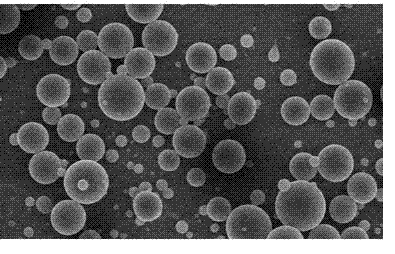

[0041] A method for preparing polyvinylpyrrolidone (PVP)-wrapped polyacrylonitrile (PAN) core-shell structure micro-nanospheres, comprising the following steps:

[0042] (1) Disperse 3.0 g of PAN powder in 100 ml of DMAc at 4°C, then shake overnight in a water-bath shaker at 60°C to form a light yellow uniform transparent solution as the inner core solution;

[0043] Dissolve 20.0 g of PVP K17 powder in 100 ml of ethanol at room temperature as the outer sheath solution;

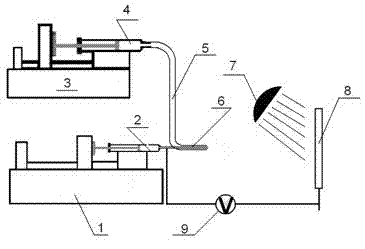

[0044] (2) Add the inner core solution and outer sheath solution obtained in step (1) into the core liquid syringe and the sheath liquid syringe respectively, and carry out high-voltage electrostatic spraying by infrared radiation-assisted high-voltage electrostatic spraying device;

[0045] The high-voltage electrostatic spraying process controls the flow rate of the outer sheath solution in the sheath fluid syringe to 1-3ml / h, and the flow rate of the inner core solution in the core fluid syringe to 0.2-0.6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com