Hydrophobic coating for controlling drug release and preparation method thereof

A hydrophobic coating and drug layer technology, applied in the fields of chemical materials and biomedicine, can solve problems such as regulation and inability to achieve hydrophobicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

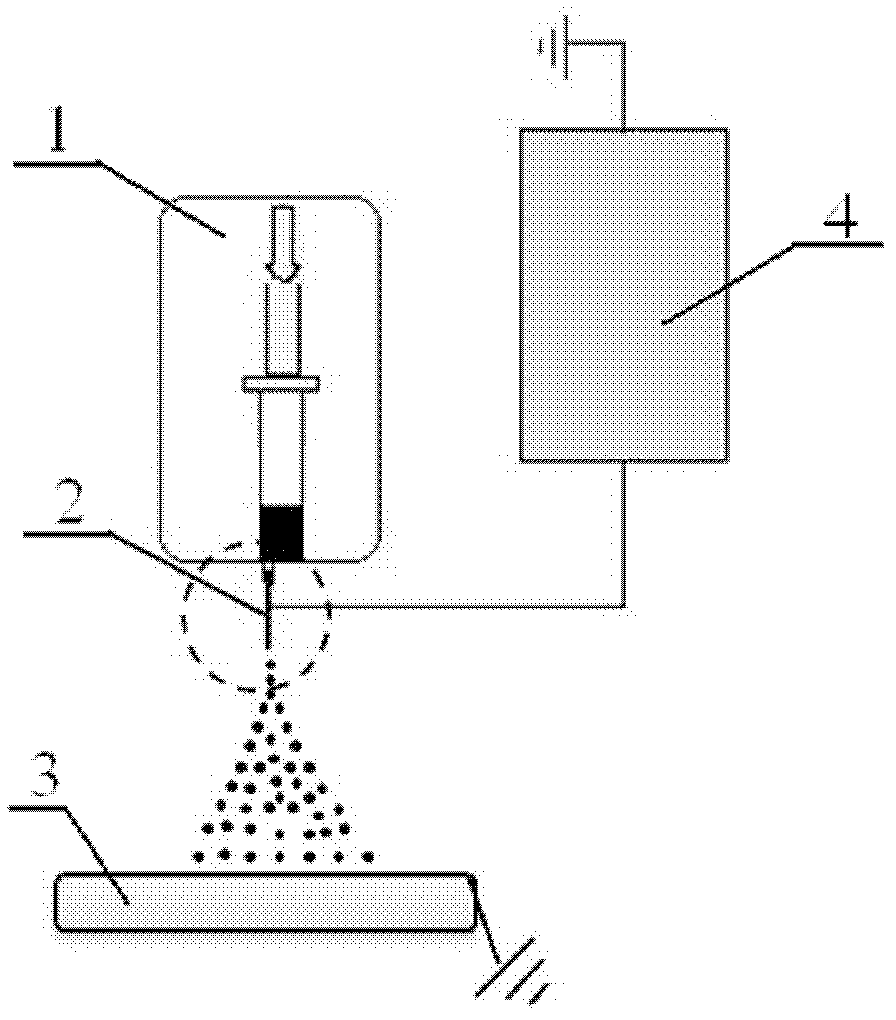

[0067] Dissolve 0.15g of polysulfone (PS, Mw=100KDa) in a mixed solvent of 15g of dichloromethane and 4g of ethanol, and stir magnetically to obtain a fully dissolved PS electrostatic spray solution.

[0068] Set the voltage of the electrospinning technical parameters to 10KV, the flow rate to 0.06ml / min, the distance from the needle to the collecting plate to 15cm, the temperature to 25°C, and the relative humidity to 50%. Use a flat plate to collect micro-nano particles, the scanning electron microscope photos and contact angles Such as figure 1 shown. The solution at the electrospray nozzle is affected by the high-voltage electric field to form a liquid jet, and then atomized into liquid particles. In the process of continuous atomization and splitting of the liquid particles, the solvent in the liquid particles evaporates rapidly, and finally, on the receiving plate Polymer micro-nano particles are obtained, the particle size of the polymer micro-nano particles ranges fro...

Embodiment 2

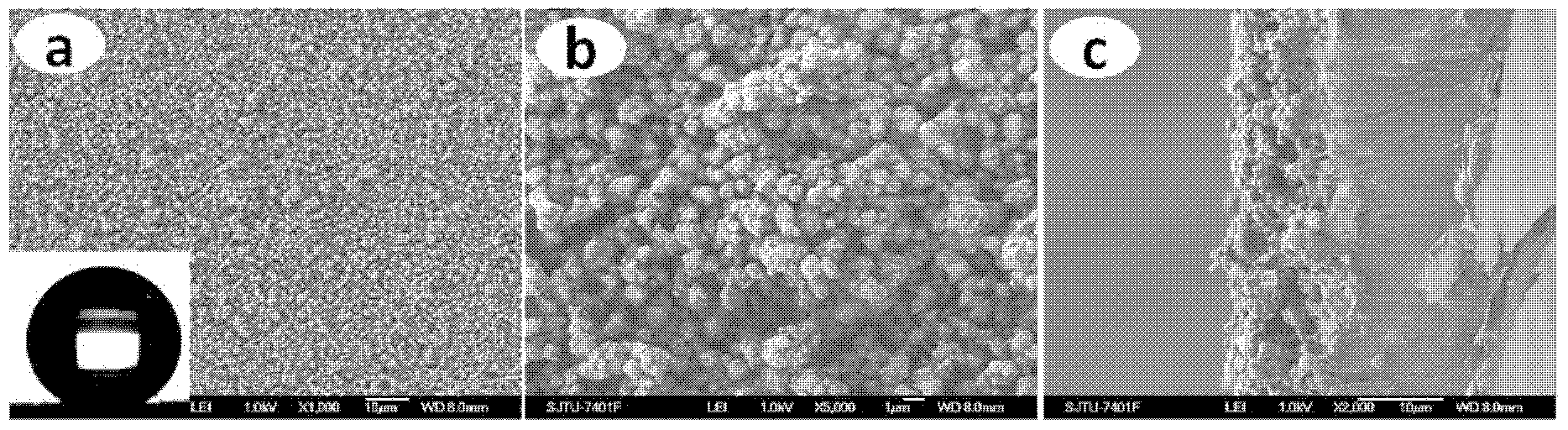

[0070] Dissolve 0.15g of polysulfone (PS, Mw=100KDa) and 0.0015g of polyvinylpyrrolidone (PVP, Mw=130KDa) in a mixed solvent of 15g of dichloromethane and 4g of ethanol, and stir magnetically to obtain fully dissolved PS and PVP Polymer mixed electrostatic spray solution. By adjusting the technical parameters of electrostatic spraying and using a flat plate as a collector, the PS / PVP composite micro-nano particle coating is collected. The initial contact angle of the coating surface is 158.3°, and the average particle size of the obtained PS / PVP particles is 856nm. Collect the electrostatic spray particle coating with a thickness of more than 10 μm, and its scanning electron microscope photos and contact angles are as follows: figure 2 shown.

Embodiment 3

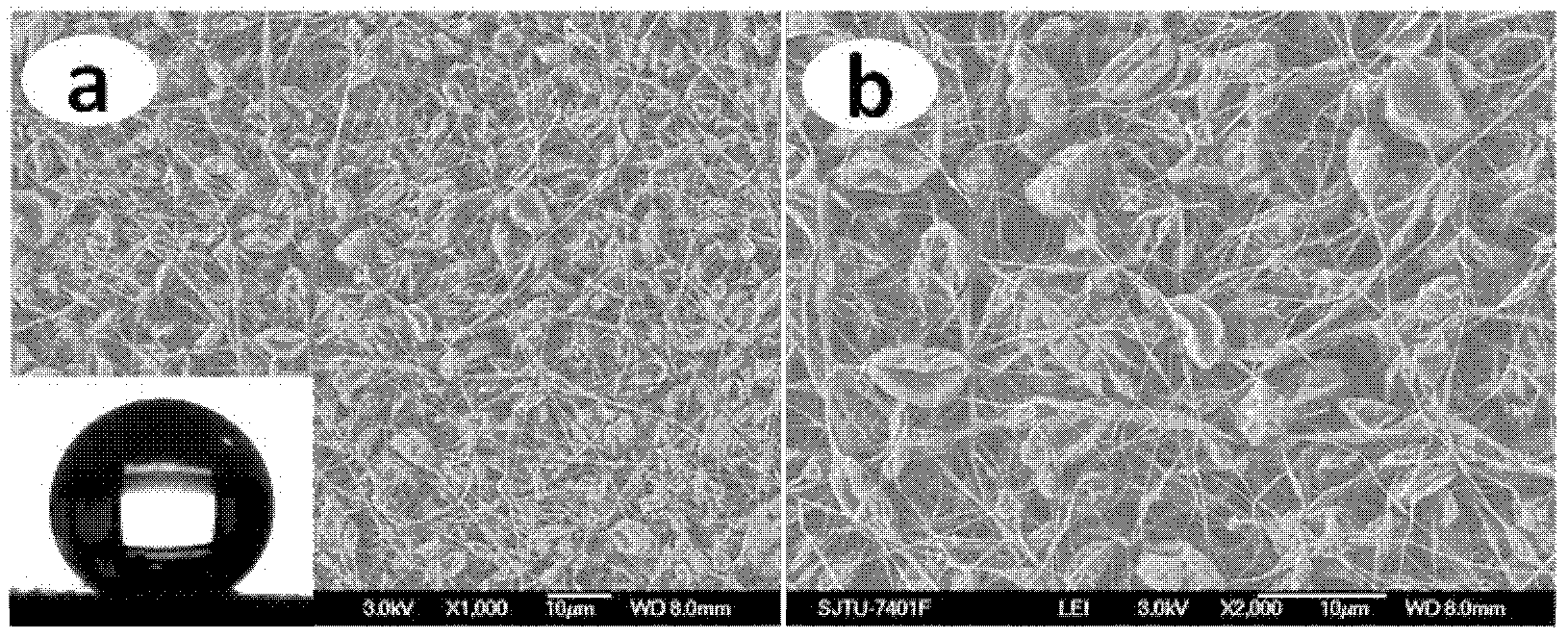

[0072] Dissolve 0.15g of polysulfone (PS, Mw=100KDa) in a mixed solvent of 10g of dichloromethane and 3g of N,N-dimethylformamide, and stir magnetically to obtain a fully dissolved PS electrostatic spray solution.

[0073] Set the voltage in the electrospinning technical parameters to 15KV, the flow rate to 0.5ml / min, the distance from the needle to the collecting plate to 10cm, the temperature to 15°C, and the relative humidity to 35%, using a flat plate to collect micro-nano particles. The solution at the electrospray nozzle is affected by the high-voltage electric field to form a liquid jet, and then atomized into liquid particles. In the process of continuous atomization and splitting of the liquid particles, the solvent in the liquid particles evaporates rapidly, and finally, on the receiving plate The polymer micro-nanoparticles are obtained, the particle size of the polymer micro-nanoparticles ranges from nanometers to micrometers, the average particle diameter of the ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com