Manganese-zirconium dual metal modified selective catalytic reduction catalyst for molecular sieve type diesel engine

A molecular sieve, bimetallic technology, applied in molecular sieve catalysts, physical/chemical process catalysts, mechanical equipment, etc., can solve the problems of vanadium-based catalysts that are more harmful to human health, small effective temperature window, catalyst loss, etc., to achieve flexible composition ratios Adjustable, increase metal loading, and improve the effect of low temperature activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] The preparation method of this catalyst modification comprises the following steps:

[0021] (1) 4~7g manganese nitrate (molecular formula: Mn(NO 3 ) 2 4H 2 O; molecular weight: 251.01) and 4-15g zirconium nitrate (molecular formula: Zr(NO 3 ) 4 ·5H 2 (2; Molecular weight: 429.32) is dissolved in 200ml deionized water, then weighing 15~18.5g model is H / ZSM-5, the molecular sieve powder that silicon aluminum ratio is 16: 1 joins in the mixed solution of manganese nitrate and zirconium nitrate, Reflux and stir in a water bath at 70-80°C for 4-6 hours for ion exchange;

[0022] (2) Remove the reflux condensing device in the ion exchange step and continue to heat, stir and impregnate at 70-80°C until the liquid components are evaporated to dryness;

[0023] (3) Dry the ion-exchanged-impregnated solid powder at 90-110° C. for 12-24 hours, and then calcinate at 550-650° C. for 2-3 hours.

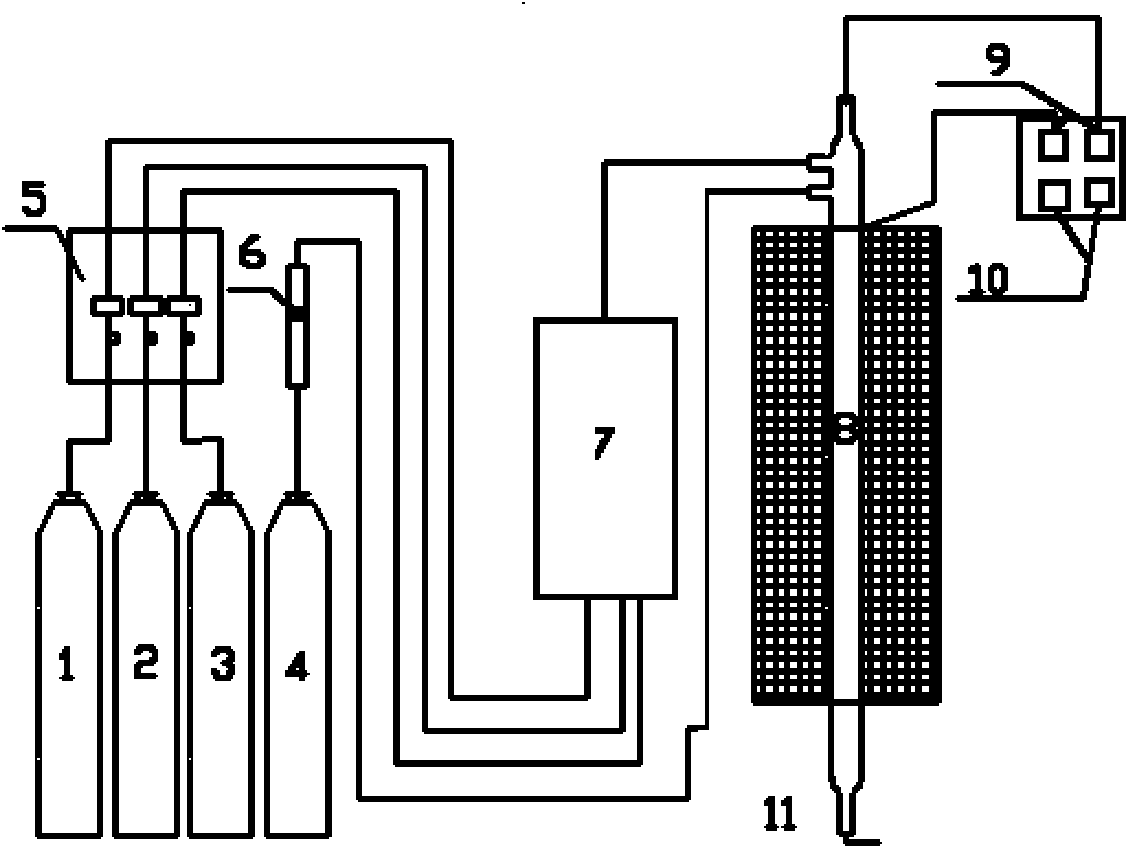

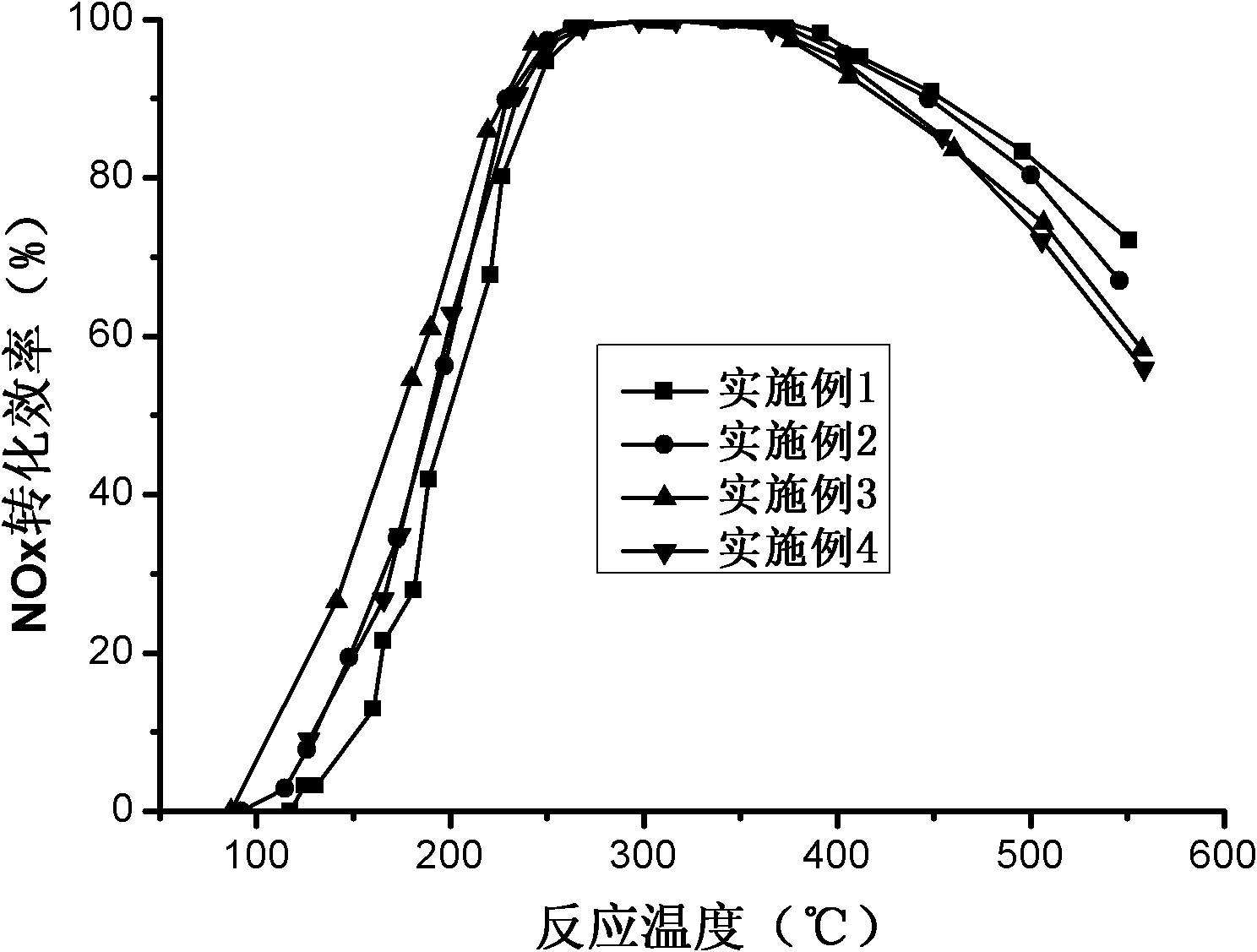

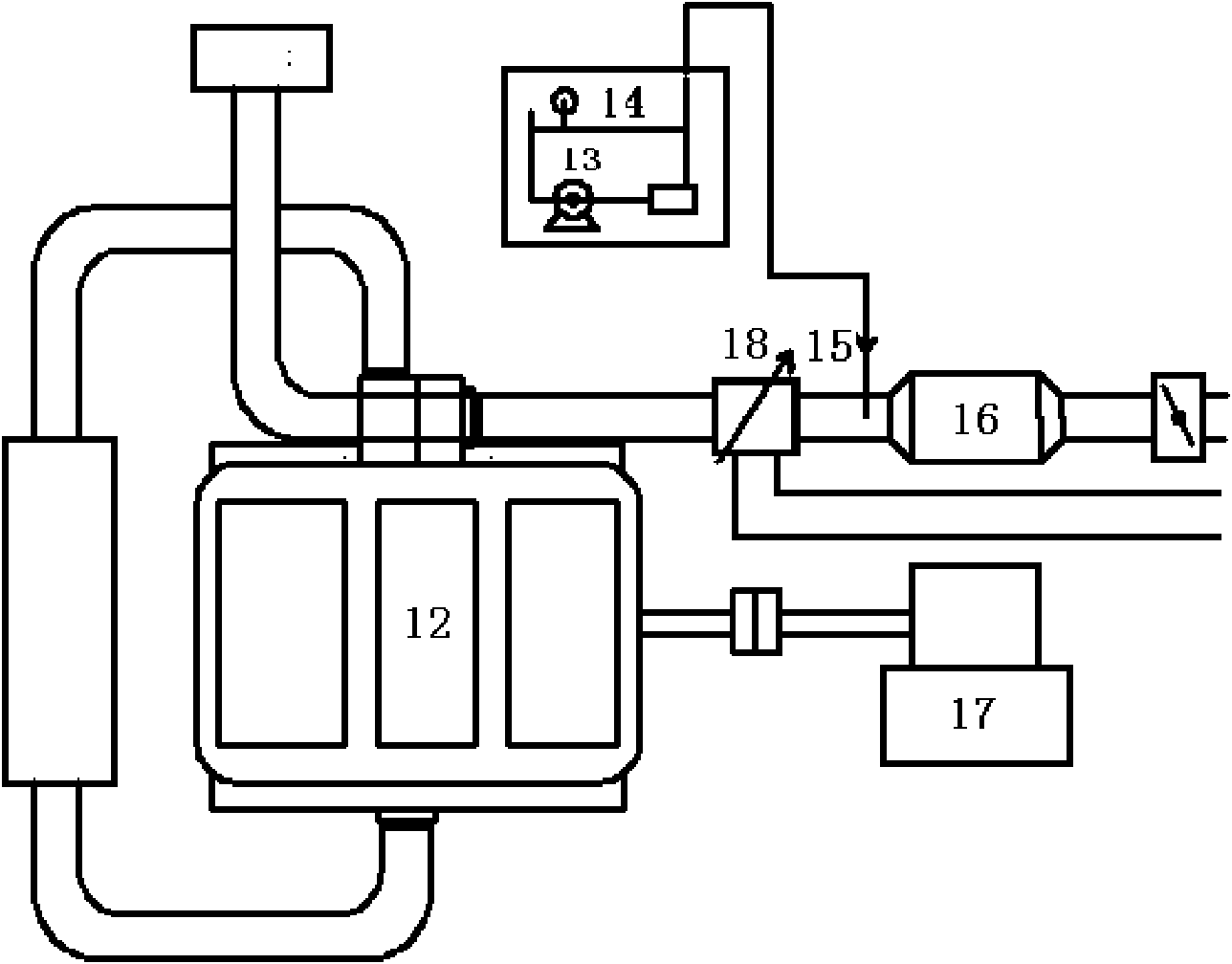

[0024] The NOx catalytic activity evaluation test of embodiment 1~4 modified mol...

Embodiment 1

[0030] (1) Modification

[0031] Dissolve 5.8g of manganese nitrate and 4.3g of zirconium nitrate in 200ml of deionized water, then weigh 17.9g of molecular sieve powder with the type H / ZSM-5 and a silicon-aluminum ratio of 16:1 and add it to the mixed solution of manganese nitrate and zirconium nitrate , and reflux and stir in a water bath at 70°C for 6h for ion exchange. Then remove the reflux condensing device, and continue to heat and stir at 70°C for impregnation until the liquid component evaporates to dryness. The ion-exchanged-impregnated solid powder was dried at 100°C for 16h, and then calcined at 550°C for 3h.

[0032] (2) load

[0033] It is determined to coat 5-6% of the coating on 1 kg of cordierite honeycomb ceramic carrier.

[0034] 20g γ-Al is required for every 100g modified molecular sieve powder 2 o 3 , 5g pseudo-boehmite, 10g cerium-zirconium, 5g polyethylene glycol (average molecular weight 4000) and 50g nitric acid ratio, weigh modified molecular siev...

Embodiment 2

[0040] (1) Modification

[0041] 5.5 g of manganese nitrate and 8 g of zirconium nitrate were dissolved in 200 ml of deionized water. Then weigh 17.2g of molecular sieve powder of type H / ZSM-5, with a silicon-aluminum ratio of 16:1, add it to the mixed solution of manganese nitrate and zirconium nitrate, and reflux and stir in a water bath at 80°C for 4 hours to carry out ion exchange. Then remove the reflux condensing device, and continue heating and stirring at 80°C for impregnation until the liquid component evaporates to dryness. The ion-exchanged-impregnated solid powder was dried at 90°C for 24h, and then calcined at 600°C for 3h.

[0042] (2) load

[0043] It is determined to coat 10-11% of the coating on 1 kg of cordierite honeycomb ceramic carrier.

[0044] 20g γ-Al is required for every 100g modified molecular sieve powder 2 o 3 , 5g pseudo-boehmite, 10g cerium-zirconium, 5g polyethylene glycol (average molecular weight 4000) and 50g nitric acid ratio, weigh mod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com