Quick-drying room temperature curing waterborne epoxy resin curing agent and preparation method thereof

A water-based epoxy resin, room temperature curing technology, used in epoxy resin coatings, coatings, etc., can solve the problems of flash rust on metal bodies and the influence of coating stability, and achieve increased molecular weight, improved compatibility, and good emulsifying ability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

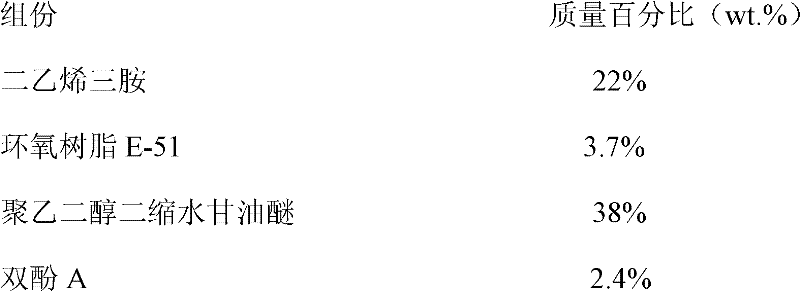

[0040] Prepare raw materials according to the mass percentage of the total materials:

[0041]

[0042]

[0043] In a reactor equipped with reflux, heating and stirring devices, add epoxy resin E-51, bisphenol A and polyethylene glycol diglycidyl ether, raise the temperature to 95°C, add triphenylphosphine, and then slowly raise the temperature to Continue the reaction at 160°C for 4 hours at a constant temperature to obtain an intermediate product. Finally, add an appropriate amount of propylene glycol methyl ether and mix well.

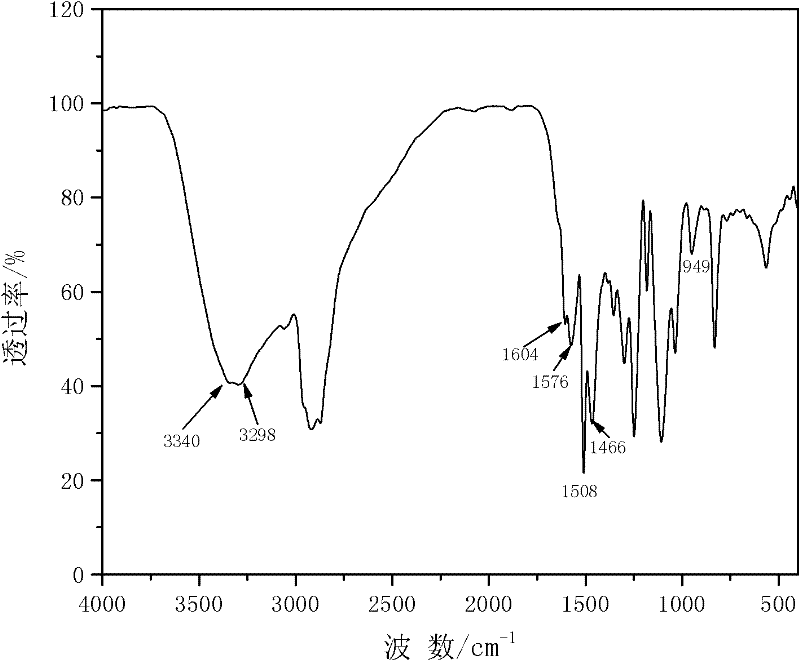

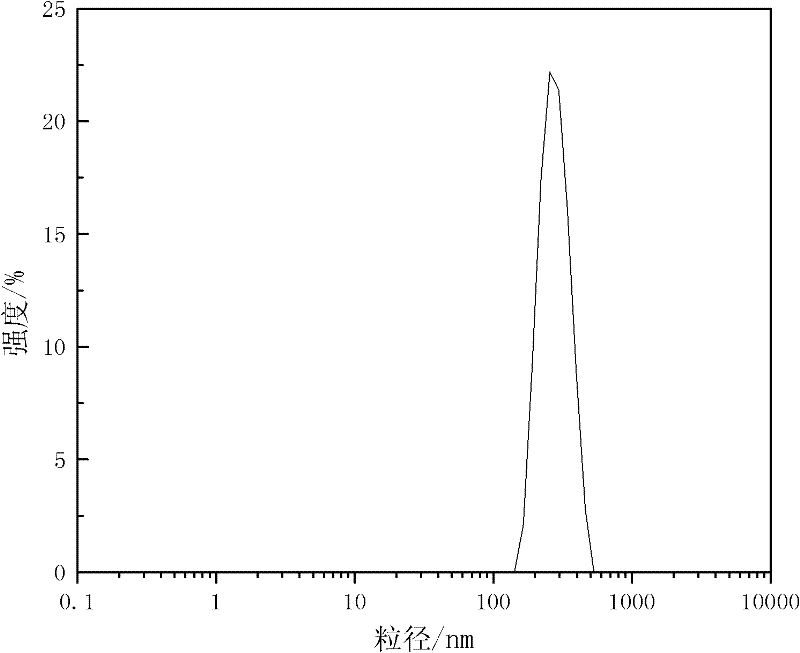

[0044] Under the condition of 60-90°C, slowly add the intermediate product dropwise to the device containing excess diethylenetriamine within about 1 hour. After the dropwise addition, continue the reaction at constant temperature for 3 hours. After the reaction is complete, remove it by distillation under reduced pressure. Unreacted amine and propylene glycol methyl ether. When the temperature is raised to 60-90°C, slowly add deionized water...

Embodiment 2

[0054] Prepare raw materials according to the mass percentage of the total materials:

[0055]

[0056]

[0057] In a reactor equipped with reflux, heating and stirring devices, add epoxy resin E-51, bisphenol A and polyethylene glycol diglycidyl ether, raise the temperature to 100 ° C, add benzyl diamine, and then slowly raise the temperature to Continue the reaction at 170°C for 4 hours at a constant temperature to obtain an intermediate product. Finally, add an appropriate amount of propylene glycol butyl ether and mix well.

[0058] Under the condition of 60-90°C, slowly add the intermediate product dropwise into the device containing excess ethylenediamine within about 1 hour. After the dropwise addition, continue the reaction at constant temperature for 3 hours. After the reaction is complete, distill under reduced pressure to remove untreated Reaction of amines and propylene glycol butyl ether. Raise the temperature to 60-90°C, slowly add deionized water dropwise...

Embodiment 3

[0066] Prepare raw materials according to the mass percentage of the total materials:

[0067]

[0068] In a reactor equipped with reflux, heating and stirring devices, add epoxy resin E-51, bisphenol A and polypropylene glycol diglycidyl ether, raise the temperature to 90°C, add triphenylphosphine, and then slowly raise the temperature to 160°C , Continue the reaction at constant temperature for 4h to obtain an intermediate product, and finally add an appropriate amount of propylene glycol methyl ether and mix well.

[0069] Under the condition of 60-90°C, slowly drop the intermediate product into the device containing excess m-xylylenediamine within about 1 hour, continue the reaction at constant temperature for 3 hours after the dropwise addition, and distill under reduced pressure after the reaction is complete Unreacted amine and propylene glycol methyl ether were removed. When the temperature is raised to 60-90°C, slowly add deionized water dropwise and stir at high ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Amine value | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com