Double-perovskite structured red fluorescent powder as well as preparation method and application thereof

A technology of red fluorescent powder and double perovskite, which is applied in the field of fluorescent materials, can solve the problems of luminous intensity attenuation, poor service stability, and complicated preparation, and achieve the effects of stable chemical properties, simple preparation process, and excellent luminous performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

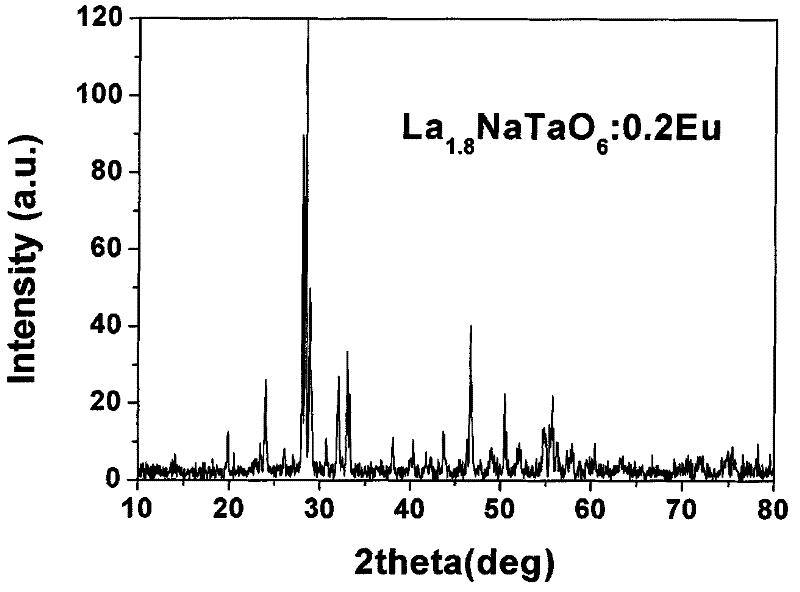

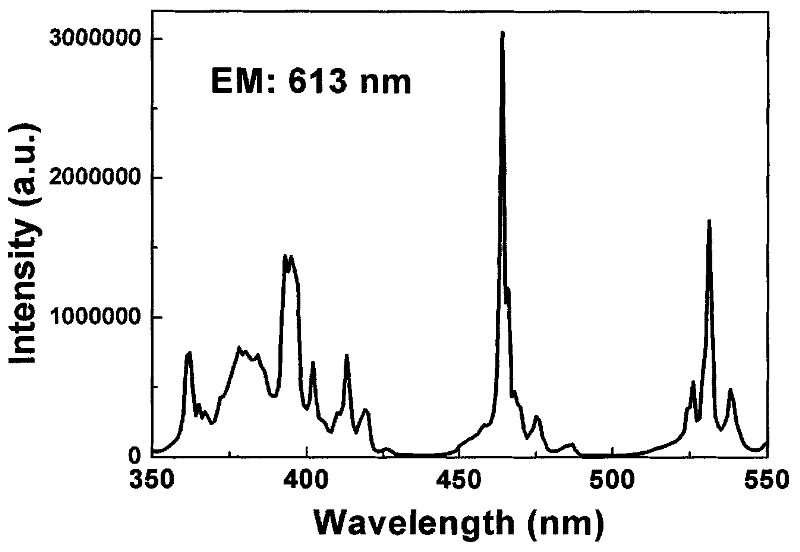

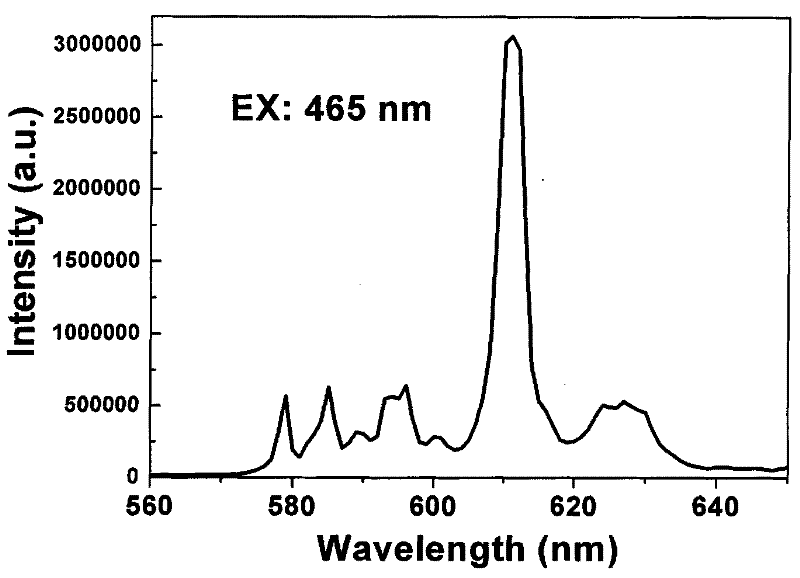

[0018] First, the raw material La 2 o 3 、Na 2 CO 3 、 Ta 2 o 5 、Eu 2 o 3 According to La 1.8 NaTaO 6 : The stoichiometric ratio of 0.2Eu is weighed, and the mixture is refined and fully mixed by ball milling; then the ball-milled mixture is put into a corundum crucible, and pre-fired in the furnace at a temperature of 1000°C. The time is 12 hours; the pre-fired powder is ground and fired again at 1400°C, and the reaction time is 12 hours; the prepared phosphor is ball milled, refined and sieved to obtain a pure-phase red fluorescent material (XRD see figure 1 ), the excitation spectrum of the sample is shown in figure 2 , the fluorescence emission intensity at 611nm under the excitation of 465nm blue light reaches 3060000 (see image 3 ), the fluorescence emission intensity at 611nm under the excitation of 465nm blue light reaches 1360000, and the fluorescence emission intensity at 617nm under the excitation of 395nm near ultraviolet light reaches 920000.

Embodiment 2

[0020] First, the raw material La 2 o 3 、Na 2 CO 3 、 Ta 2 o 5 、Eu 2 o 3 According to La 1.8 NaTaO 6 : The stoichiometric ratio of 0.2Eu is weighed, and the mixture is refined and fully mixed by ball milling; then the ball-milled mixture is put into a corundum crucible, and pre-fired in the furnace at a temperature of 500 ° C. The time is 24h; the powder obtained by pre-calcination is ground and fired again at 1000°C, and the reaction time is 12h; the powder obtained by pre-fire is ground and fired again at 1400°C, and the reaction time is 12h. The prepared fluorescent powder is ball milled, refined and sieved to obtain a pure-phase red fluorescent material, and the fluorescent emission intensity of the sample at 611nm under the excitation of 465nm blue light reaches 3,500,000.

Embodiment 3

[0022] First, the raw material La 2 o 3 、Na 2 CO 3 、 Ta 2 o 5 、Eu 2 o 3 According to La 1.8 NaTaO 6 : Weigh the stoichiometric ratio of 0.2Eu, use ball milling to refine the mixture and fully mix; then put the ball milled mixture into a corundum crucible, and directly fire it in the furnace without pre-firing , the temperature is 1400°C, and the time is 48h. The prepared fluorescent powder is ball-milled, refined and sieved to obtain a pure-phase red fluorescent material, and the fluorescent emission intensity of the sample at 611nm under the excitation of 465nm blue light reaches 2,000,000.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com