Micron/nanocone array of germanium and preparation method thereof

A nanocone and array technology, applied in the field of germanium micro/nanocone arrays, can solve the problems of high temperature, complex equipment, high cost, etc., and achieve the effect of simple preparation and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

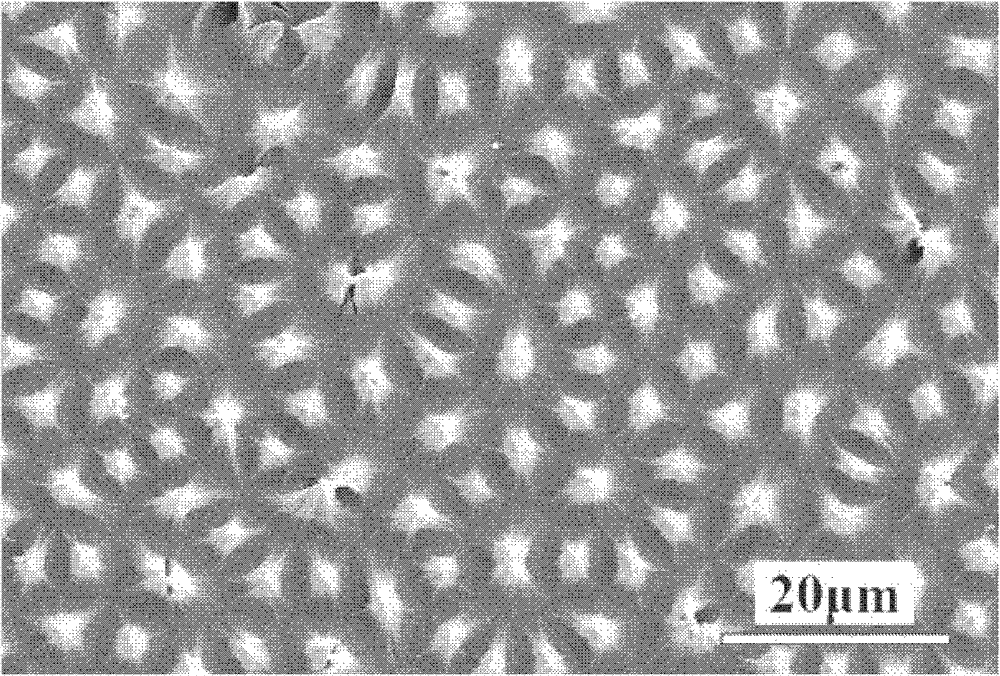

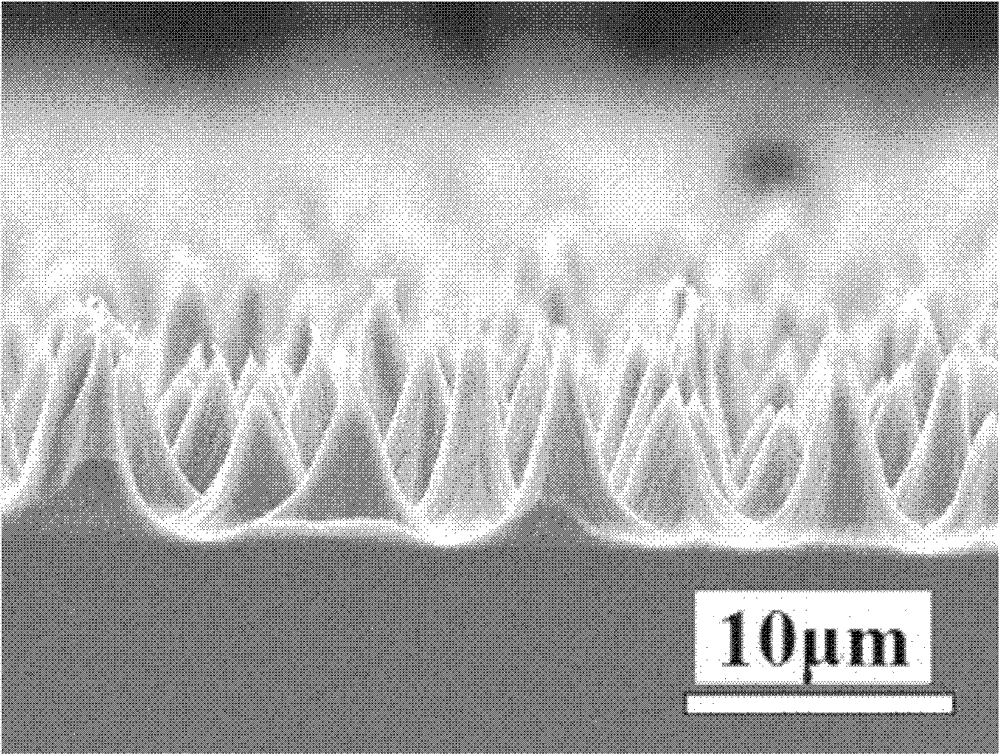

[0018] Prepare an aqueous solution containing 2M hydrofluoric acid and 0.01M hydrogen peroxide as an etching solution, add the above etching solution that is 50% of the volume of the plastic centrifuge tube into a 50mL plastic centrifuge tube; then ultrasonically clean the Immerse the single-crystal germanium sheet with a crystal orientation of into the etching solution in the above-mentioned centrifuge tube; put the above-mentioned centrifuge tube containing the etching solution into a constant temperature water bath, and place it in a constant temperature water bath with a temperature of 60°C Treat for 24 hours; take out the germanium sheet, rinse it with distilled water, and dry it naturally; finally, under a hydrogen atmosphere, anneal and reduce it at a temperature of 540 ° C for 3 hours to obtain a germanium micron / nanocone composed of multiple germanium micron / nanocones. A nanocone array, wherein the germanium micro / nanocone in the array has a length of 15 μm and a tip ...

Embodiment 2

[0020] Prepare an aqueous solution containing 5M hydrofluoric acid and 0.1M hydrogen peroxide as an etching solution, add the above-mentioned etching solution that is 80% of the volume of the plastic bottle into a 100mL plastic bottle; then ultrasonically clean the crystal orientation with absolute ethanol and distilled water Immerse the single crystal germanium sheet into the etching solution in the above plastic bottle; put the above plastic bottle containing the etching solution into a constant temperature water bath, and treat it in a constant temperature water bath at a temperature of 30°C for 18 Hours; take out the germanium sheet, rinse it with distilled water, and dry it naturally; finally, under a hydrogen atmosphere, anneal and reduce it at a temperature of 550°C for 4 hours, and then obtain a micron / nanocone of germanium composed of a plurality of micron / nanocones of germanium An array, wherein the germanium micro / nano cones in the array have a length of 10 μm and a...

Embodiment 3

[0022] Prepare an aqueous solution containing 7M hydrofluoric acid and 0.4M hydrogen peroxide as an etching solution, add the above etching solution that is 90% of the volume of the reaction kettle in a 50mL reactor; then ultrasonically clean the crystal with absolute ethanol and distilled water Immerse the single crystal germanium sheet into the etching solution in the above reaction kettle; put the above reaction kettle containing the etching solution into a constant temperature water bath, and treat it in a constant temperature water bath with a temperature of 30°C 18 hours; after taking out the germanium sheet, rinse it with distilled water and dry it naturally; finally, under a hydrogen atmosphere, anneal and reduce at a temperature of 550°C for 5 hours, and the micron / nano A cone array, wherein the germanium micro / nano cones in the array have a length of 40 μm and a tip diameter of 50-100 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com