A kind of preparation method of mercury-free catalyst for the synthesis of vinyl chloride by acetylene method

A mercury catalyst and vinyl chloride technology, which is applied in the field of preparation of mercury-free catalysts, can solve the problems of high content of precious metals in the catalyst, hindered industrial application, volume impregnation or multiple volume impregnation, etc., and achieves the effect of high catalytic activity and stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

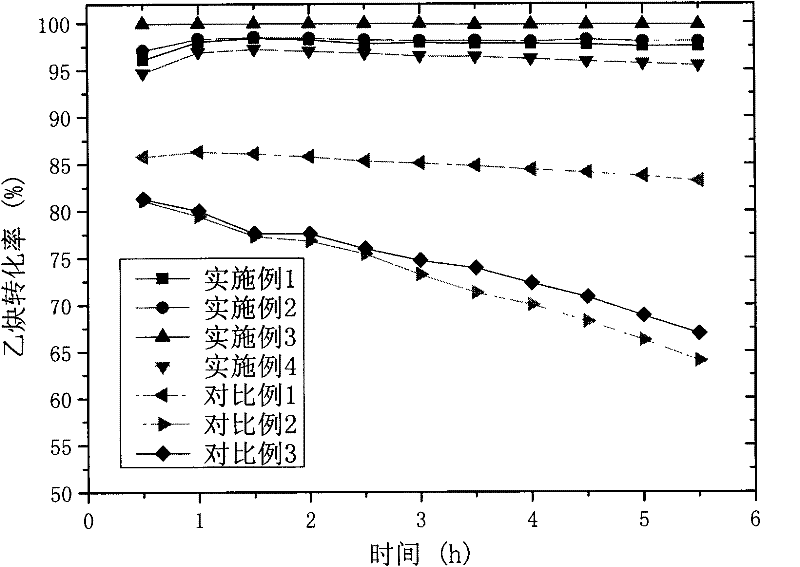

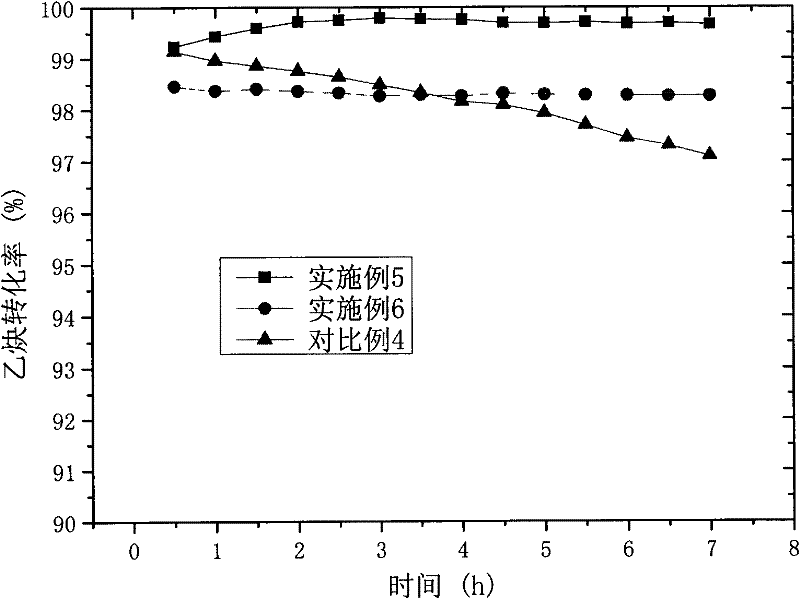

Embodiment 1

[0029] At 80°C, add 150g of coconut shell carbon carrier with a carbon tetrachloride adsorption value of 60% to 300g of 1mol / L hydrochloric acid aqueous solution, stir for 4 hours, then suction filter, wash with water until pH = 5, at 120°C Dry for 6h. Add the above hydrochloric acid-treated coconut shell charcoal carrier into 300g ethanol solution containing 10% ethylenediamine, under the condition of ultrasonic power 200W and frequency 59KHz, perform ultrasonic modification at 60°C for 3h, then suction filter, and dry at 120°C for 4h . Take 100g of the coconut shell charcoal carrier after the above-mentioned modified treatment and add it to 250g containing 0.15g AuCl 3 , 8g CuCl 2 In the aqueous solution of 200W power and 59KHz frequency ultrasonic treatment at room temperature for 2h, suction filtration, 120°C drying for 4h, to obtain the acetylene method synthesis of vinyl chloride catalyst. The catalyst is at 160°C, 640h -1 Catalytic activity and stability were evalua...

Embodiment 2

[0031] The coconut shell charcoal carrier that hydrochloric acid is processed joins in the dehydrated alcohol solution that 300g contains 10%KH-550 silane coupling agent, all the other are the same as embodiment 1, the obtained catalyst evaluation result sees figure 1 .

Embodiment 3

[0033] AuCl during catalyst preparation 3 The addition amount is 0.6g, CuCl 2 The addition of is 6.0g, and all the other are with embodiment 1, and the obtained catalyst evaluation result sees figure 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com