Skeleton Diclofenac Potassium Sustained-release Pellet Capsules and Production Process

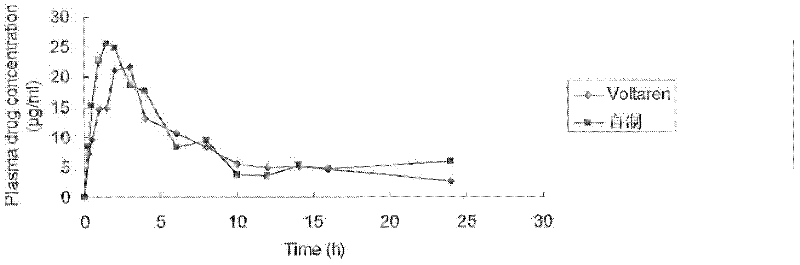

A technology of diclofenac potassium and sustained-release pellets, applied in the field of medicine, can solve the problems of unstable blood drug concentration, toxic and side effects, etc., and achieve the effects of lasting effective blood drug concentration, good reproducibility and excellent release curve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Example 1 Production of 1000 skeleton-type diclofenac potassium sustained-release pellets and capsules (75 mg / grain in terms of diclofenac potassium), the used raw materials, adjuvant materials and their weight ratios are:

[0033] Diclofenac Potassium 75g

[0034] Carbomer 974P 12g

[0035] Microcrystalline Cellulose 192g

[0038] Tween 80 15g

[0039] Its preparation method is as follows:

[0040] (1) Mix 75g of the main drug diclofenac potassium, 12g of the hydrophilic gel skeleton agent carbomer 974P and 192g of the diluent microcrystalline cellulose to obtain a solid powder mixture; mix 3g of the antioxidant sodium sulfite and 3g of the anti-sticking agent calcium chloride and absorption enhancer Tween-80 15g were respectively dissolved in wetting agent water to prepare solutions with a mass volume ratio of 6%, 6% and 15% respectively; the above soluti...

Embodiment 2

[0044] Embodiment 2 Production of skeleton type diclofenac potassium sustained-release pellet capsules 1000 (75mg / grain in terms of diclofenac potassium), used raw materials, adjuvant materials and weight ratio thereof are:

[0045] Diclofenac Potassium 75g

[0046] Carbomer 974P 9g

[0047] Microcrystalline Cellulose 180g

[0050] Tween 80 15g

[0051] Its preparation method is as follows:

[0052] (1) Mix 75g of main drug diclofenac potassium, 21g of hydrophilic gel skeleton agent carbomer 974P and 180g of diluent microcrystalline cellulose; mix 3g of antioxidant sodium sulfite, 6g of anti-sticking agent calcium chloride and absorption promoter Tween-80 15g was dissolved in water respectively to prepare solutions with mass volume ratios of 6%, 12% and 15% respectively; the above solutions were respectively added to the above solid powder mixture, and stirred ev...

Embodiment 3

[0056] Embodiment 3 Production skeleton type diclofenac potassium sustained-release pellet capsule 1000 (75mg / grain in terms of diclofenac potassium), used bulk drug, auxiliary material and its weight ratio are:

[0057] Main ingredient Diclofenac Potassium 75g

[0058] Hydrophilic gel matrix agent Carbomer 974P 9g

[0059] Insoluble matrix ethyl cellulose 45g

[0060] Thinner Microcrystalline Cellulose 147g

[0061] Antioxidant Sodium Sulfite 3g

[0062] Anti-sticking agent calcium chloride 6g

[0063] Absorption enhancer Tween 80 15g

[0064] The release rate of the above-mentioned skeleton-type diclofenac potassium sustained-release pellets and capsules was measured by the slurry method, the rotation speed was 100 rpm, the phosphate buffer solution with pH 6.2 was used as the dissolution medium, and the water temperature was 37°C. According to the measurement, 32% of 0.5h dissolution, 53% of 2h dissolution, 8h dissolution of more than 70%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com