A flame retardant and its synthetic process

A polyphosphate, chloroalkyl technology, applied in the direction of phosphorus organic compounds, textiles and papermaking, fiber processing, etc., can solve environmental pollution, a large number of problems, and achieve good thermal stability, simple synthesis process, long-lasting resistance. flammable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

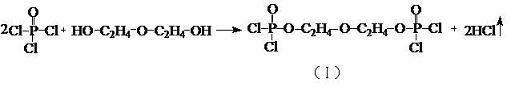

[0032] A kind of synthetic technique of chlorinated alkyl polyphosphate flame retardant comprises the steps:

[0033] (1) Add 217.7g (1.42mol) of POCl to a four-necked flask equipped with an electric stirrer, a constant pressure dropping funnel, a thermometer and a vacuum absorber connected to hydrochloric acid 3 (Phosphorus oxychloride), turn on the electric stirrer and hydrochloric acid vacuum absorber, control the temperature of the water bath at 25-30°C, slowly add 75g (0.71mol) of diethylene glycol dropwise, a large amount of hydrogen chloride gas is generated, dropwise in 0.5-3 hours After the completion of the dropwise addition, continue the reaction until no hydrogen chloride gas is generated to obtain the reaction intermediate, which is left in the four-necked bottle, and directly proceeds to the next step of synthesis;

[0034] (2) Refit the four-neck bottle containing the intermediate in the above step (1) into a reaction device with an electric stirrer, a constant ...

Embodiment 2

[0037] Same as Example 1, but in the second step of the reaction, 1.5 g of anhydrous aluminum trichloride is used as the catalyst Lewis acid to replace 1.6 g of titanium tetrachloride, and the product is washed with water and evaporated under reduced pressure to obtain the finished product.

[0038] Results: Yield 82%, phosphorus content 10.9%; chlorine content: 23%.

Embodiment 3

[0040] Same as Example 1, but in the second step of the reaction, the catalyst Lewis acid is replaced by 1.5g of magnesium chloride for 1.6g of titanium tetrachloride, and the product is washed with water and evaporated under reduced pressure to obtain the finished product.

[0041] Results: Yield 75%, phosphorus content 10.9%; chlorine content: 23%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com