A kind of organic solar cell and preparation method thereof

A solar cell, organic technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems such as difficulty in control, and achieve the effect of improving energy conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

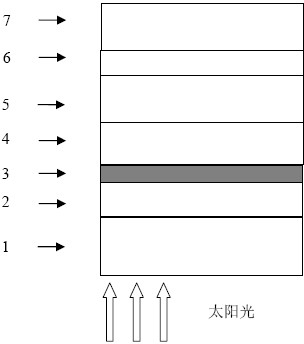

[0042] figure 1 It is the structural diagram of embodiment 1 of the present invention, and transparent insulating substrate 1 adopts quartz glass; Transparent electrode 2 adopts FTO stripe electrode, and its sheet resistance is 20 ohms / □; Anode modification layer 3 adopts SiO2 silicon dioxide material; Layer 4 adopts CuPc copper phthalocyanine thin film; second photosensitive layer 5 adopts C60 thin film; buffer layer 6 adopts organic material Alq3 thin film; high reflectivity electrode 7 adopts Al aluminum thin film electrode.

[0043] Prepare as follows:

[0044] Polished quartz glass with a thickness of 1.1mm is selected as the transparent insulating substrate 1, and the quartz glass is cleaned for 2-3 hours by ultrasonic method;

[0045] A layer of ITO conductive film is grown on one side of the quartz glass by sputtering as the transparent electrode 2, and the thickness of the ITO film is 100nm;

[0046] Photolithographically etch the ITO conductive film into the requi...

Embodiment 2

[0054] See figure 1 The transparent insulating substrate 1 adopts quartz glass; the transparent electrode 2 adopts ITO stripe electrodes, and its square resistance is 15 ohms / □; the anode modification layer 3 adopts LiF lithium fluoride material; the first photosensitive layer 4 adopts CuPc copper phthalocyanine thin film; The second photosensitive layer 5 is made of C60 thin film; the buffer layer 6 is made of organic material Alq3 thin film; the high reflectivity electrode 7 is made of Al aluminum thin film electrode.

[0055] The specific preparation is as follows:

[0056] Polished quartz glass with a thickness of 1.5mm is selected as the transparent insulating substrate 1, and the quartz glass is cleaned for 3 hours by an ultrasonic method;

[0057] A layer of ITO conductive film is grown on one side of the quartz glass by sputtering as the transparent electrode 2 . The thickness of the ITO film is 120nm;

[0058] Photoetching the ITO conductive film into the required...

Embodiment 3

[0066] like figure 1 , the transparent insulating substrate 1 is made of quartz glass; the transparent electrode 2 is made of ITO stripe electrode, and its square resistance is 17 ohms / □; the anode modification layer 3 is made of TiOx material; the first photosensitive layer 4 is made of pentacene film; the second photosensitive layer 5 adopts C60 thin film; buffer layer 6 adopts organic material BCP thin film; high reflectivity electrode 7 adopts Ag silver thin film electrode.

[0067] Prepare as follows:

[0068] Polished quartz glass with a thickness of 3.2mm is selected as the transparent insulating substrate 1, and the quartz glass is cleaned for 4 hours by ultrasonic method;

[0069] A layer of ITO conductive film is grown on one side of the quartz glass by sputtering as the transparent electrode 2 . The thickness of the ITO film is 150nm;

[0070]Photoetching the ITO conductive film into the required striped electrode pattern as the anode of the solar cell;

[0071...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com