Absorbable Vascular Stent

A vascular stent and polylactic acid technology, applied in medical science, surgery and other directions, can solve the problems of unfavorable support of blood vessels and low mechanical strength of vascular stent, and achieve the effect of good mechanical strength and good supporting effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

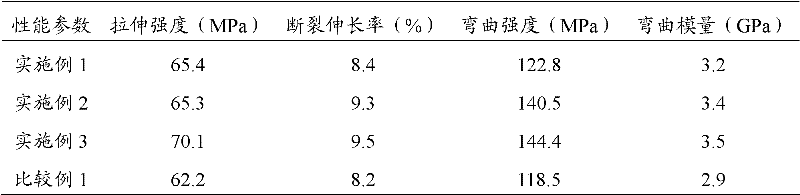

[0063] The L-polylactic acid with an intrinsic viscosity of 2.5dL / g and the D-polylactic acid with an intrinsic viscosity of 2.3dL / g were mixed in a banbury mixer at the ratio of 90:10, 70:30, and 50:50, Banburying at 200°C for 5 minutes to obtain a polylactic acid stereocomplex;

[0064] The melting point of the polylactic acid stereocomplex was tested respectively, and the results showed that the polylactic acid stereocomplex obtained in Example 1 had two melting peaks, and the melting temperatures were 175°C and 209°C respectively; the polylactic acid obtained in Example 2 The stereocomplex has two melting peaks, and the melting temperatures are 176°C and 210°C respectively; the polylactic acid stereocomplex obtained in Example 1 has one melting peak, and the melting temperature is 225°C;

[0065] The polylactic acid stereocomplexes were respectively pressed into 2 mm thick sheets in a flat vulcanizing machine at 200° C. while hot.

Embodiment 4

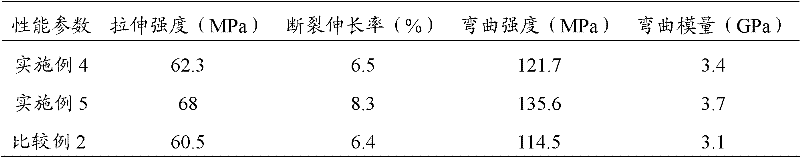

[0075] Mix L-polylactic acid with an intrinsic viscosity of 2.5dL / g, D-polylactic acid with an intrinsic viscosity of 2.3dL / g, and micron-sized hydroxyapatite in an internal mixer, and banbury at 200°C for 5 minutes to obtain Polylactic acid stereocomplex, wherein the mass ratio of the total amount of L-polylactic acid and D-polylactic acid to hydroxyapatite is 90:10, and the mass ratio of L-polylactic acid and D-polylactic acid is 90:10 ;

[0076] Test the melting point of the polylactic acid stereocomplex, which has two melting peaks, and the melting temperatures are 176°C and 205°C respectively;

[0077] While hot, the polylactic acid stereocomplex was pressed into a sheet with a thickness of 2 mm in a flat vulcanizing machine at 200°C.

[0078] The sheet was crystallized at 120° C. for 1 hour, and the mechanical strength of the sheet was tested. See Table 2 for the results. Table 2 shows the test results of the mechanical strength of the sheets provided in Examples 4-5 an...

Embodiment 5

[0080] Mix L-polylactic acid with an intrinsic viscosity of 2.5dL / g, D-polylactic acid with an intrinsic viscosity of 2.3dL / g, and micron-sized hydroxyapatite in an internal mixer, and banbury at 200°C for 5 minutes to obtain Polylactic acid stereocomplex, wherein the mass ratio of the total amount of L-polylactic acid and D-polylactic acid to hydroxyapatite is 90:10, and the mass ratio of L-polylactic acid and D-polylactic acid is 70:30 ;

[0081] Test the melting point of the polylactic acid stereocomplex, which has two melting peaks, and the melting temperatures are 175°C and 216°C respectively;

[0082] While hot, the polylactic acid stereocomplex was pressed into a sheet with a thickness of 2 mm in a flat vulcanizing machine at 200°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com