A kind of purification process of cytochrome c

A cytochrome and process technology, applied in the purification process of cytochrome C and the field of cytochrome C purification by cutting-edge hydrophobic chromatography, can solve the problems of low production efficiency, low utilization rate of chromatographic fillers, and many purification steps, and achieve high production efficiency. , the purification effect is good, the effect of reducing the purification cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Example 1: Separation and purification of cytochrome C in porcine heart by frontier hydrophobic chromatography

[0022] (1) Extraction of cytochrome C from pig heart

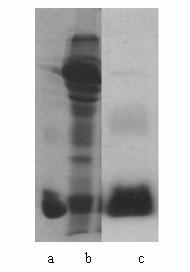

[0023] Take 1 kg of fresh pig heart, remove the fatty connective tissue, mince it, add 400 mL of water, adjust the pH to 4.0 with 1.0 mol / L sulfuric acid, stir at room temperature for 2 h, filter with gauze to remove the residue, in order to fully extract the residue Re-extract for 1 h under the above conditions. Remove the residue and combine the two extracts, then adjust the pH to 7.0 with 1.0 mol / L ammonia water, let it stand at 4°C, and finally centrifuge, collect the supernatant, and filter to obtain about 760 mL of crude extraction solution. attached figure 1 The middle band b is the SDS-PAGE picture of the cytochrome C crude extract.

[0024] (2) Ammonium sulfate precipitation crude purification of cytochrome C in pig heart

[0025] Add solid ammonium sulfate to the obtained crude extract to ma...

Embodiment 2

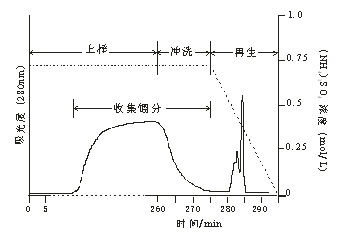

[0028] Example 2: Separation and purification of cytochrome C from porcine heart by hydrophobic chromatography in elution mode

[0029] With 3 mol / L (NH 4 ) 2 SO 4 + 50 mmol / L PBS (pH 7.0) to equilibrate a hydrophobic chromatographic column (10 × 0.46 cm I.D.) equipped with PEG600 stationary phase, inject 2 mL of the cytochrome C solution obtained in (2) of Example 1 into the equilibrated In a hydrophobic column, the protein is eluted with a linear gradient such that (NH 4 ) 2 SO 4The concentration was reduced to 0 mol / L within 30 min, and the cytochrome C fraction was collected. The flow rate throughout the chromatographic process was 1.0 mL / min, and the detection wavelength was 280 nm. After testing, the purity of the purified cytochrome C was 99.4%, and only 0.8 mg of high-purity cytochrome C could be obtained in one purification. The yield of purified cytochrome C in this process is only 0.8 mg / (hour.g filler).

Embodiment 3

[0030] Example 3: Purification of Cytochrome C from Porcine Heart by Classical Adsorption Chromatography

[0031] (1) Artificial zeolite column adsorption and elution

[0032] At a flow rate of 1.0 mL / min, 70 mL of the cytochrome C solution obtained in (1) in Example 1 was loaded onto a chromatographic column filled with 5 g of artificial zeolite, so that the artificial zeolite fully adsorbed the cytochrome C extract and became For bright red. Then the artificial zeolite was taken out from the column and washed three times with distilled water, 0.2% NaCl and distilled water, each time for 20 min. Repack the washed artificial zeolite column with 25% (NH4) at a flow rate of 2.0 mL / min 2 SO 4 The solution was eluted, and the red cytochrome C fraction was collected.

[0033] (2) Purification of cytochrome C by precipitation with ammonium sulfate and trichloroacetic acid

[0034] Add a certain amount of solid ammonium sulfate to the cytochrome C fraction collected in (1) so ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com