A kind of preparation method of strontium chloroborate whisker

A technology of strontium chloroborate and whiskers, which is applied in the field of inorganic chemical material preparation, can solve problems such as the preparation of strontium chloroborate whiskers that have not yet been seen, and achieve the effects of rich varieties, high product purity, and easy industrial production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

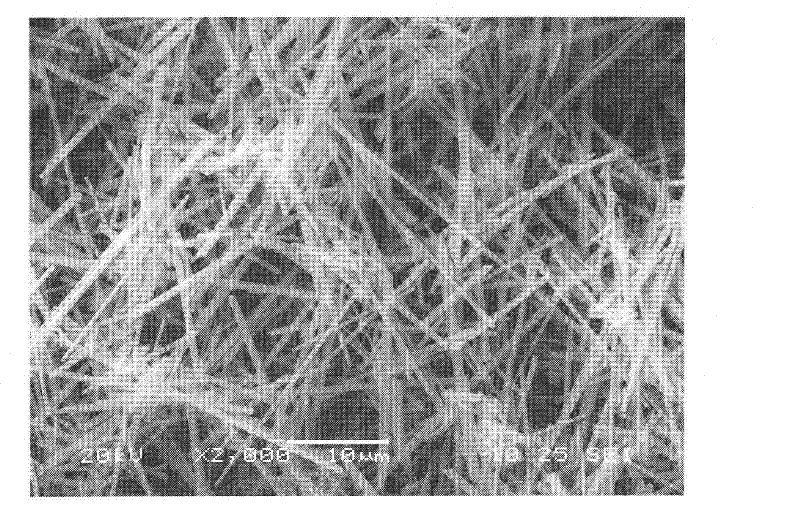

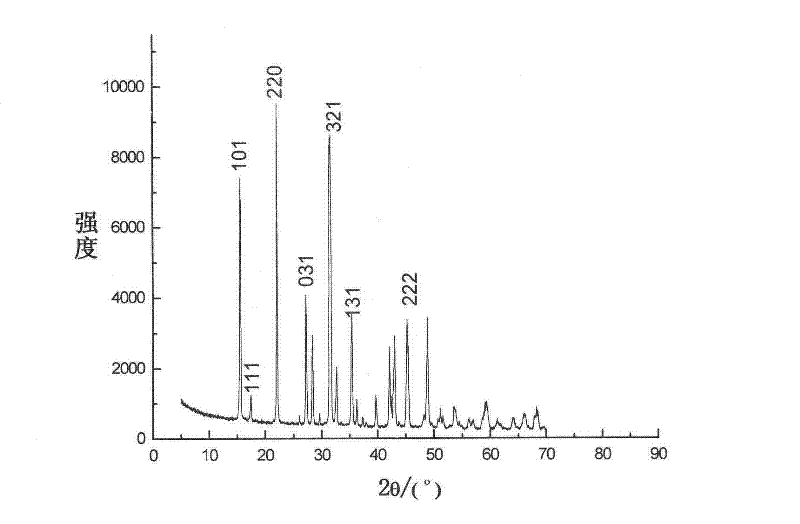

Image

Examples

Embodiment 1

[0020] Embodiment 1 A kind of preparation method of strontium chloroborate whisker, comprises the following steps:

[0021] (1) Add 1.33g of strontium-containing raw material—strontium chloride (SrCl 2 ·6H 2 O), 0.62g boron-containing raw material -- boric acid (H 3 BO 3 ), 1.00 g of flux——potassium chloride (KCl) were mixed evenly and then ground to a particle size of less than 60 mesh to obtain a mixed raw material.

[0022] Wherein: the molar ratio of strontium in the strontium-containing raw material to boron in the boron-containing raw material is 1:2; the flux accounts for 50% of the total mass of the strontium-containing raw material and the boron-containing raw material.

[0023] (2) Put the mixed raw materials in a high-temperature furnace, raise the temperature to 650° C. at a heating rate of 5° C. / min, keep the temperature for 6 hours, and cool naturally to obtain a sintered product.

[0024] (3) Put the sintered product into deionized water, soak for 2 hours, f...

Embodiment 2

[0026] Embodiment 2 A kind of preparation method of strontium chloroborate whisker, comprises the following steps:

[0027] (1) Add 1.33g of strontium-containing raw material—strontium chloride (SrCl 2 ·6H 2 O), 0.70g boron-containing raw material - boron oxide (B 2 o 3 ), 2.03g of flux—sodium chloride (NaCl) are mixed evenly and then ground to a particle size of less than 60 mesh to obtain a mixed raw material.

[0028] Wherein: the molar ratio of strontium in the strontium-containing raw material to boron in the boron-containing raw material is 1:4; the flux accounts for 100% of the total mass of the strontium-containing raw material and the boron-containing raw material.

[0029] (2) Put the mixed raw materials in a high-temperature furnace, raise the temperature to 800° C. at a heating rate of 10° C. / min, keep the temperature for 15 hours, and cool naturally to obtain a sintered product.

[0030] (3) Put the sintered product into deionized water, soak for 12 hours, fil...

Embodiment 3

[0032] Embodiment 3 A kind of preparation method of strontium chloroborate whisker, comprises the following steps:

[0033] (1) Add 1.33g of strontium-containing raw material—strontium chloride (SrCl 2 ·6H 2 O), 2.38g boron-containing raw material——borax (Na 2 B 4 o 7 10H 2 (2), 7.42g flux—potassium chloride (KCl) are mixed evenly and ground to a particle size of less than 60 mesh to obtain a mixed raw material.

[0034] Wherein: the molar ratio of strontium in the strontium-containing raw material to boron in the boron-containing raw material is 1:5; the flux accounts for 200% of the total mass of the strontium-containing raw material and the boron-containing raw material.

[0035] (2) Put the mixed raw materials in a high-temperature furnace, raise the temperature to 750° C. at a heating rate of 8° C. / min, keep the temperature for 8 hours, and cool naturally to obtain a sintered product.

[0036] (3) Put the sintered product into deionized water, soak for 4 hours, filt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com