Preparation method of fibroin blending material with gradually degrading performance

A technology of blending and silk fibroin, which is applied in medical preparations of non-active ingredients, pharmaceutical formulations, medical science, etc., can solve problems such as limited degradation ability, poor physical properties, and less research on drug sustained-release carrier materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

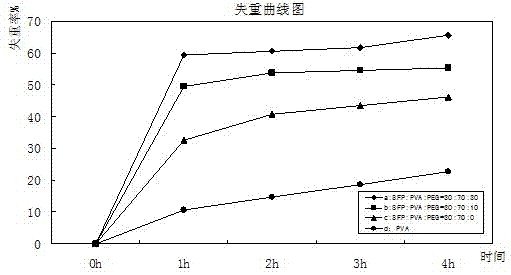

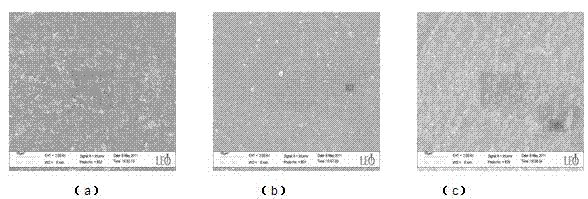

Image

Examples

Embodiment Construction

[0024] The preparation process of the present invention is as follows:

[0025] Step 1: Prepare small-molecular-weight silk fibroin peptide (SFP, molecular weight less than 5000Da) powder by salt-dissolving and enzymatic hydrolysis.

[0026] Step 2: Dissolve (or disperse) the small-molecular-weight silk fibroin peptide powder prepared in the first step in water, blend it with polyvinyl alcohol (PVA) aqueous solution, and stir for 10-60 minutes to form hydrogen between the two molecules key, there is a certain binding. The mass ratio of silk fibroin peptide powder to polyvinyl alcohol is 1:1-9, and the degree of polymerization of polyvinyl alcohol is 1700-2400.

[0027] The third step: Add polyethylene glycol (PEG) to the blend liquid obtained in the second step, and the mass of polyethylene glycol is 5-15% of the mass sum of silk fibroin peptide powder and polyvinyl alcohol, and stir to react. The time is 5-10 hours, and the aqueous solution of the blended material is obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com