Zinc oxide/graphene oxide composite optical switch material and electrochemical preparation method thereof

A graphene composite and zinc oxide technology, which is applied in the preparation of electricity and energy conversion materials, and in the field of light, can solve the problems of excessive coating film thickness and uneven film thickness, and achieve simple production conditions, control of photoelectric performance, and low production cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

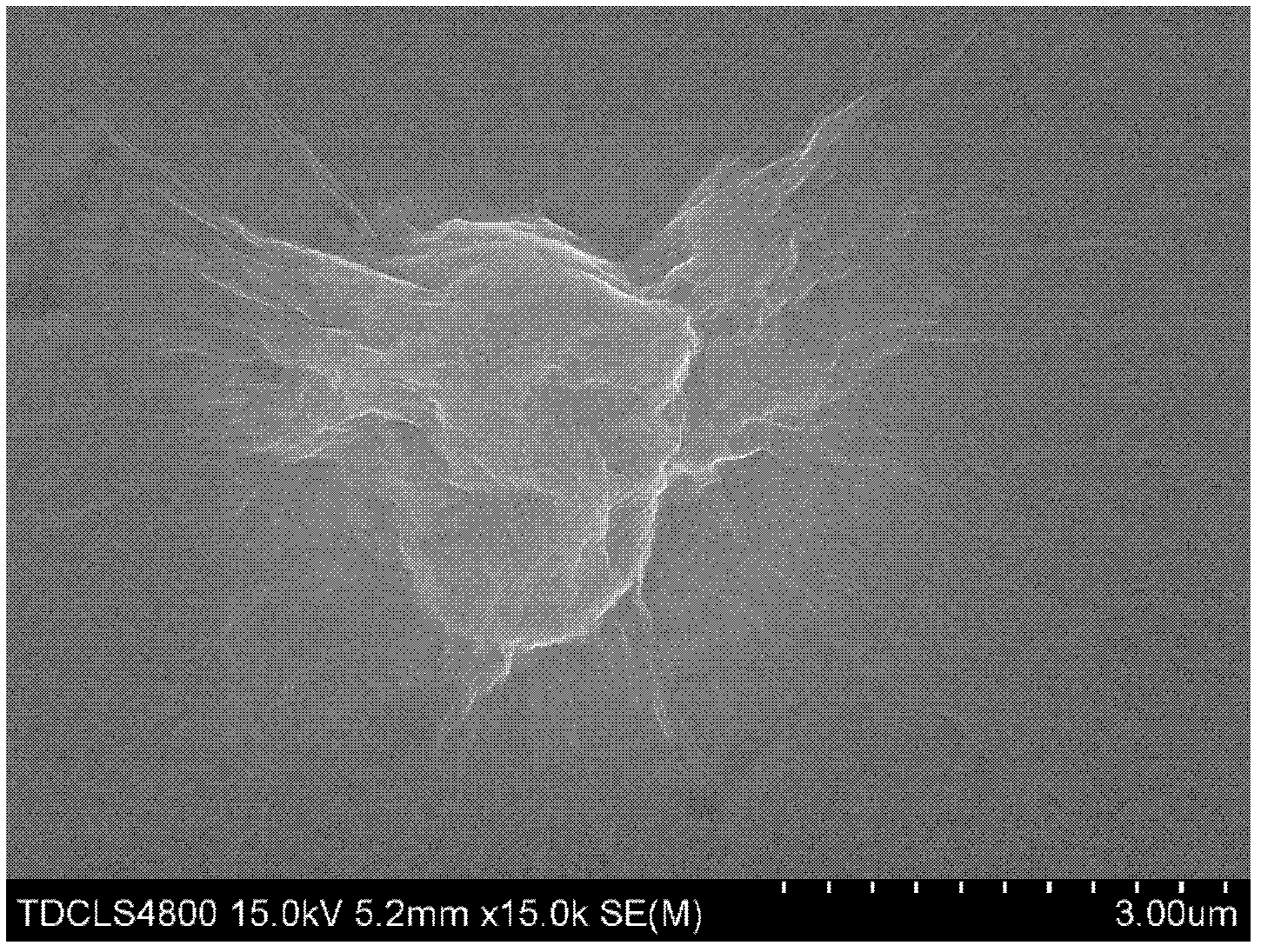

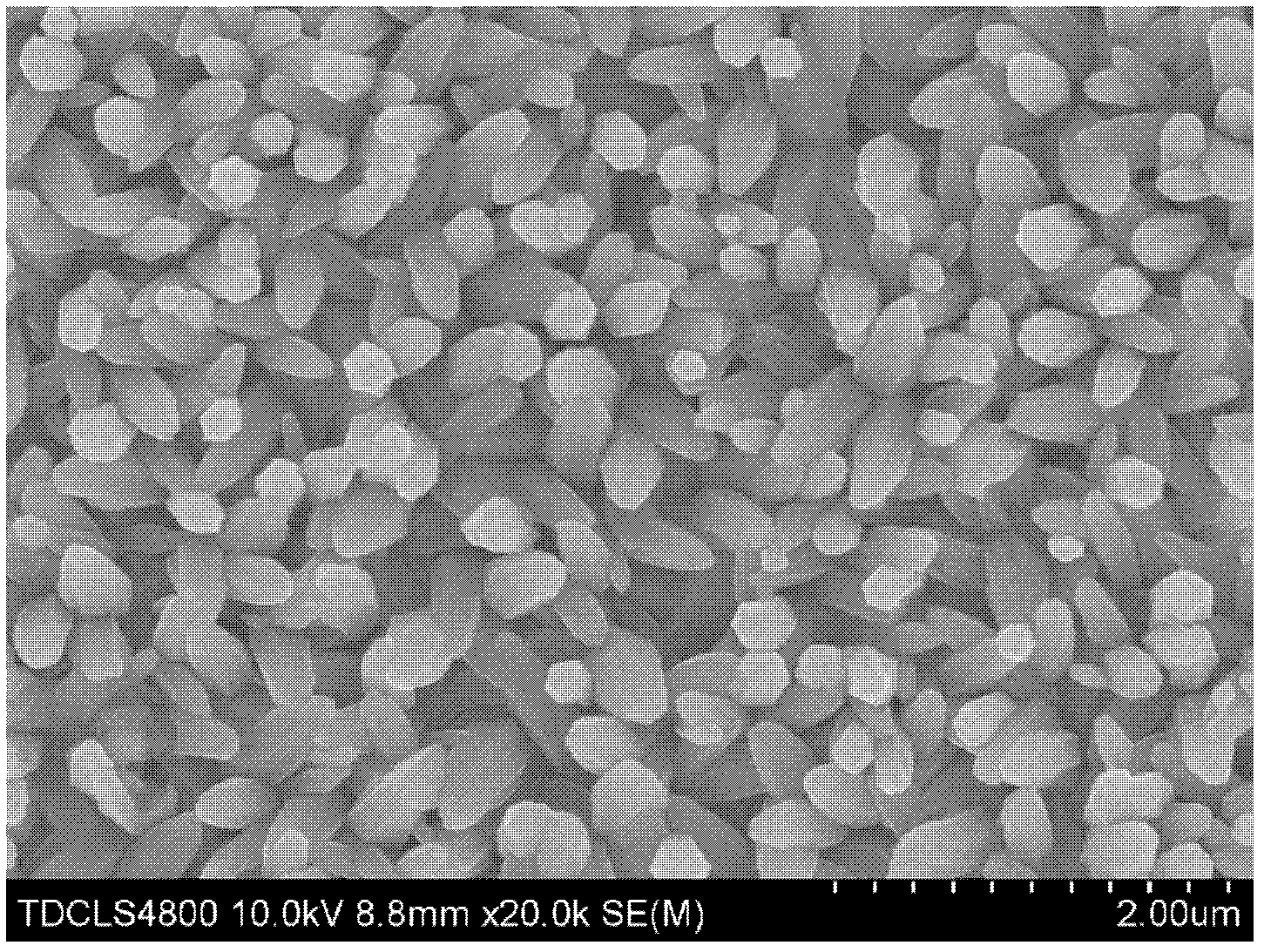

[0022] Weigh 10 mg of graphene oxide, disperse it in 50 ml of deionized water, and ultrasonically disperse it evenly, then electrochemically deposit it using a three-electrode system. The working electrode is made of ITO conductive glass (resistance 15Ω / square), and the deposition area is 1 cm 2 , the counter electrode is made of platinum, and the reference electrode is made of calomel electrode. Constant current 0.5mA / cm at 25°C 2 Deposit for 150 seconds. The product was blown dry under nitrogen to obtain an ITO electrode covered with a graphene oxide film. Weigh 297.5mg Zn(NO 3 ) 2 ·6H 2 O was dispersed in 50ml of deionized water and electrochemically deposited using a three-electrode system. The working electrode was a prepared ITO electrode covered with a graphene oxide film, and the deposition area was 1cm. 2 , the counter electrode is made of platinum, and the reference electrode is made of calomel electrode. Constant voltage -1V deposition time 20 minutes at 65°C...

Embodiment 2

[0025] Weigh 10 mg of graphene oxide, disperse it in 50 ml of deionized water, and ultrasonically disperse it evenly, then electrochemically deposit it using a three-electrode system. The working electrode is made of ITO conductive glass (resistance 15Ω / square), and the deposition area is 1 cm 2 , the counter electrode is made of platinum, and the reference electrode is made of calomel electrode. Constant current 0.5mA / cm at 25°C 2 Deposit for 150 seconds. The product was blown dry under nitrogen to obtain an ITO electrode covered with a graphene oxide film. Weigh 148.75mg Zn(NO 3 ) 2 ·6H 2 O was dispersed in 50ml of deionized water and electrochemically deposited using a three-electrode system. The working electrode was a prepared ITO electrode covered with a graphene oxide film, and the deposition area was 1cm. 2, the counter electrode is made of platinum, and the reference electrode is made of calomel electrode. Constant voltage -1V deposition time 20 minutes at 6...

Embodiment 3

[0028] Weigh 10 mg of graphene oxide, disperse it in 50 ml of deionized water, and ultrasonically disperse it evenly, then electrochemically deposit it using a three-electrode system. The working electrode is made of ITO conductive glass (resistance 15Ω / square), and the deposition area is 1 cm 2 , the counter electrode is made of platinum, and the reference electrode is made of calomel electrode. Constant current 0.5mA / cm at 25°C 2 Deposit for 225 seconds. The product was blown dry under nitrogen to obtain an ITO electrode covered with a graphene oxide film. Weigh 223.12mg Zn(NO 3 ) 2 ·6H 2 O was dispersed in 50ml of deionized water and electrochemically deposited using a three-electrode system. The working electrode was a prepared ITO electrode covered with a graphene oxide film, and the deposition area was 1cm. 2 , the counter electrode is made of platinum, and the reference electrode is made of calomel electrode. Constant voltage -1V deposition time 15 minutes at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com