Manufacturing method of cylindrical lithium ion battery

A lithium-ion battery, cylindrical technology, applied in the manufacture of electrolyte batteries, battery electrodes, non-aqueous electrolyte batteries, etc., can solve the problems of low power consumption of LED lighting, as small as tens of milliamps to hundreds of milliamps, waste, etc. , to achieve the effect of reducing equipment investment, production and labor costs, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

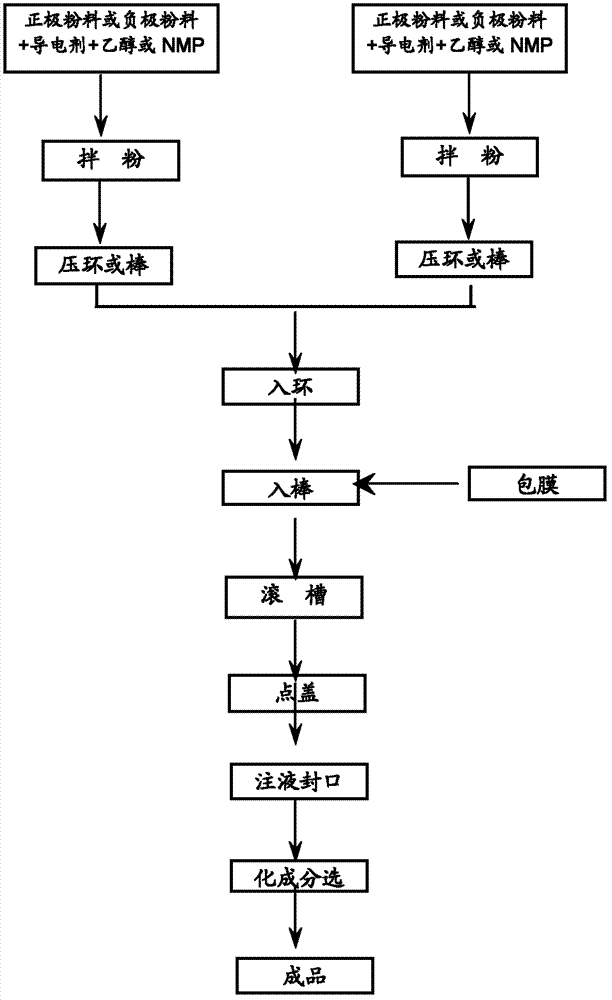

[0054] Example 1 Preparation of 18650 lithium manganate battery

[0055] Positive electrode ratio: 90% (by weight) LiMn 2 o 4 + 8% acetylene black + 2 conductive graphite, dry powder and stir evenly, then add 10% of the total weight of positive electrode powder NMP, continue to stir evenly, the electrolyte is 1MLiPF 6 +EC+DME+DMC(1:1:1).

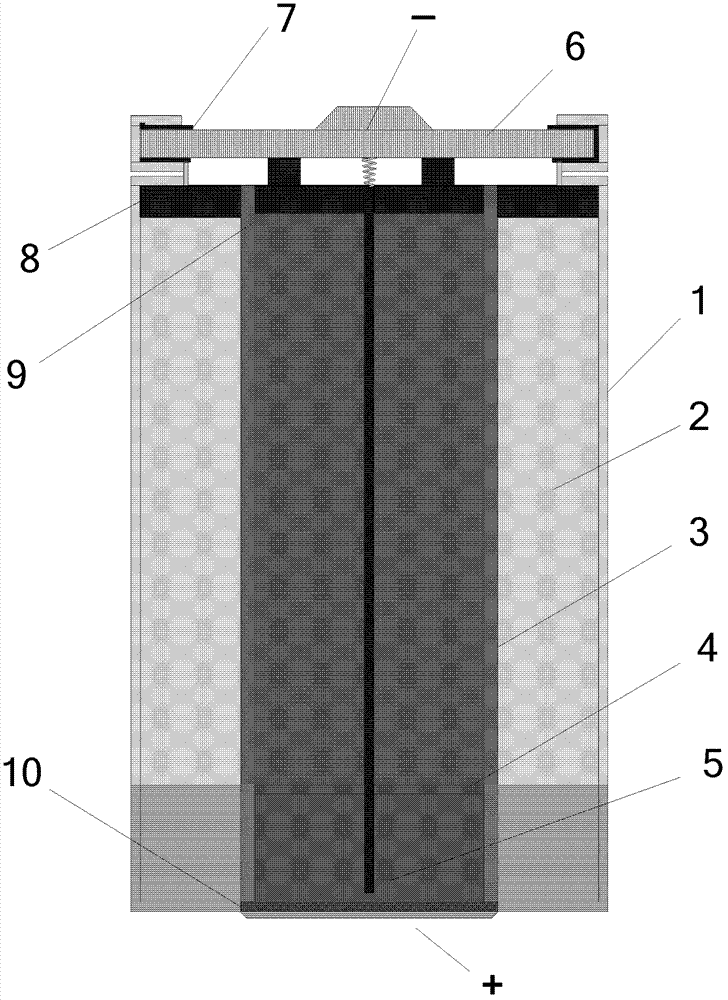

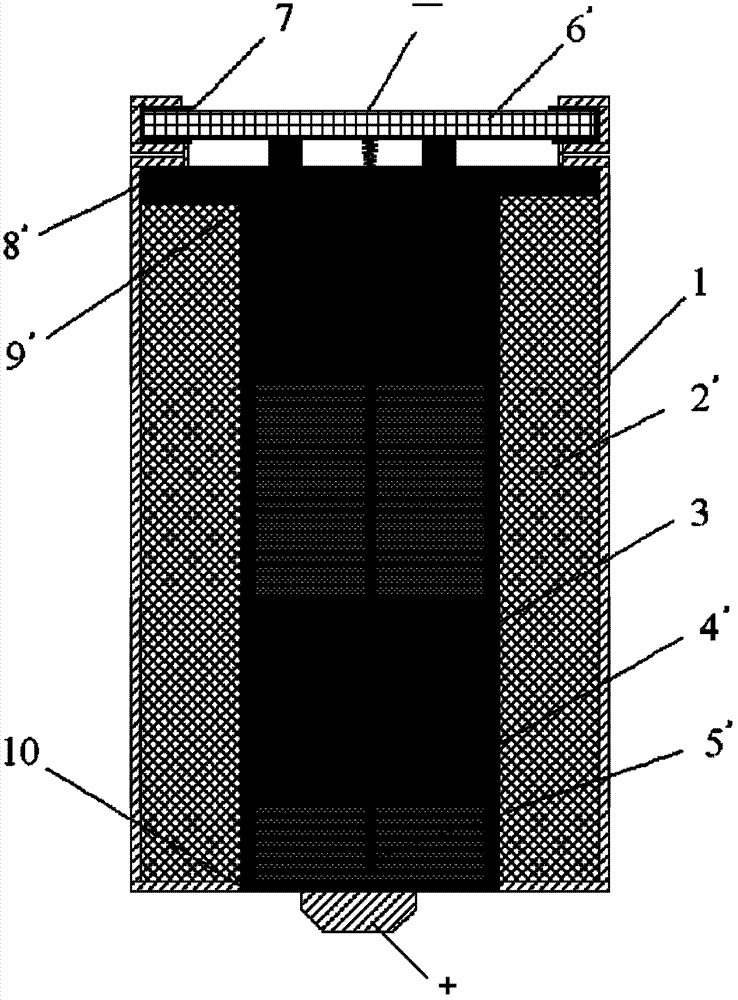

[0056] The stirred lithium manganate powder is pressed into a positive electrode powder ring in a self-made ring machine, and three powder rings are added to each battery. The size of the powder ring is: outer diameter 17.5mm, inner diameter 8.0mm, height 19.0mm , the weight of each powder ring is: 30.0±0.5g; the outer diameter of the negative pole is 8.0mm, the height is 58.0mm, and the weight of each powder ring is: 14.0±0.5g. Wrap the negative rod with 2 layers of 20-micron-thick polypropylene diaphragm, put it into the positive powder ring, and then inject 9.0g of electrolyte, seal it in a rolling groove, and leave it at room temperat...

Embodiment 2

[0061] Example 2 Preparation of 26650 type lithium iron phosphate battery

[0062] Positive electrode ratio: 90% (weight ratio) lithium iron phosphate + 8% acetylene black + 2% conductive graphite, dry powder and stir evenly, then add 10% of the total weight of positive electrode powder NMP, continue to stir evenly, the electrolyte is 1MLiPF 6 +EC+DME+DMC(1:1:1).

[0063] The stirred positive electrode powder is pressed into a positive electrode powder ring in a self-made ring machine, and three powder rings are added to each battery. The size of the powder ring is: outer diameter 25.2mm, inner diameter 15.0mm, height 19.0mm, each The weight of each powder ring is: 48.0±0.5g; the outer diameter of the negative pole is 15.0mm, the height is 58.0mm, and the weight of each powder ring is: 21.0±0.5g. Wrap the negative electrode with 2 layers of 20-micron-thick polypropylene diaphragm, put it into the positive electrode ring, and then inject 20g of electrolyte, after being sealed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| luminous efficiency | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com