Method for preparing MnZn ferrite with adding silane coupling agent

A silane coupling agent and ferrite technology, applied in the field of ferrite magnetic materials, can solve the problems of uneven microstructure of sintered body, low molding density, uneven distribution, etc., to reduce loss, reduce agglomeration, and reduce particles the effect of reunion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1: the concrete steps of this embodiment are as follows:

[0029] The first step is to prepare MnZn ferrite nanopowder

[0030] MnZn ferrite nano-powder is prepared according to the method disclosed in patent CN101276668A, except that in this example, after the black manganese-zinc ferrite nano-crystal is prepared, it is directly dried in an oven at 80°C to obtain a powder with an average particle size of 26nm. MnZn ferrite nanopowder, and its nominal chemical formula is Mn 0.65 Zn 0.35 Fe 2 o 4 .

[0031] The second step is to introduce the silane coupling agent

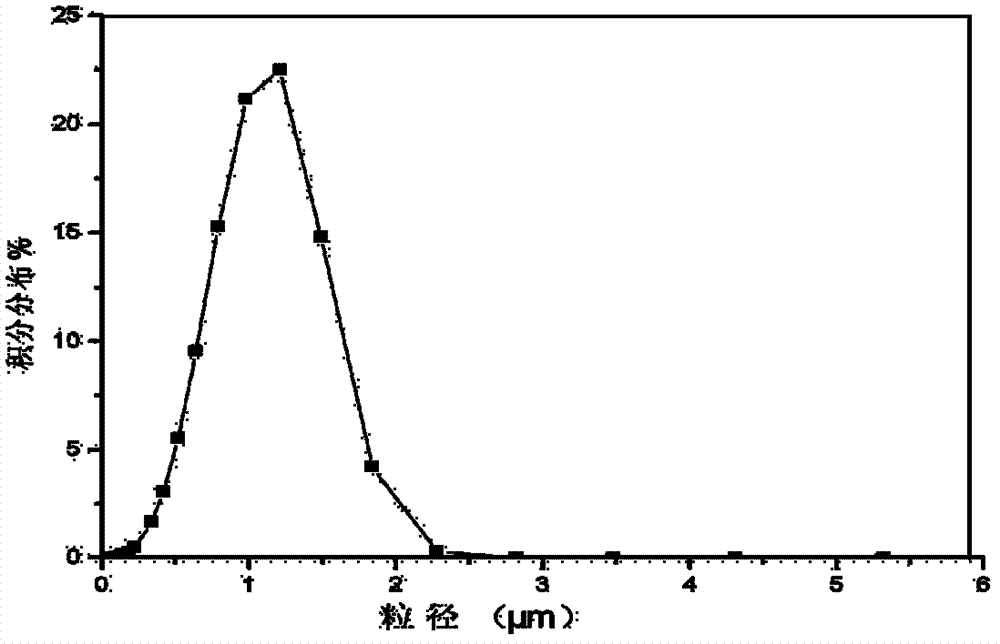

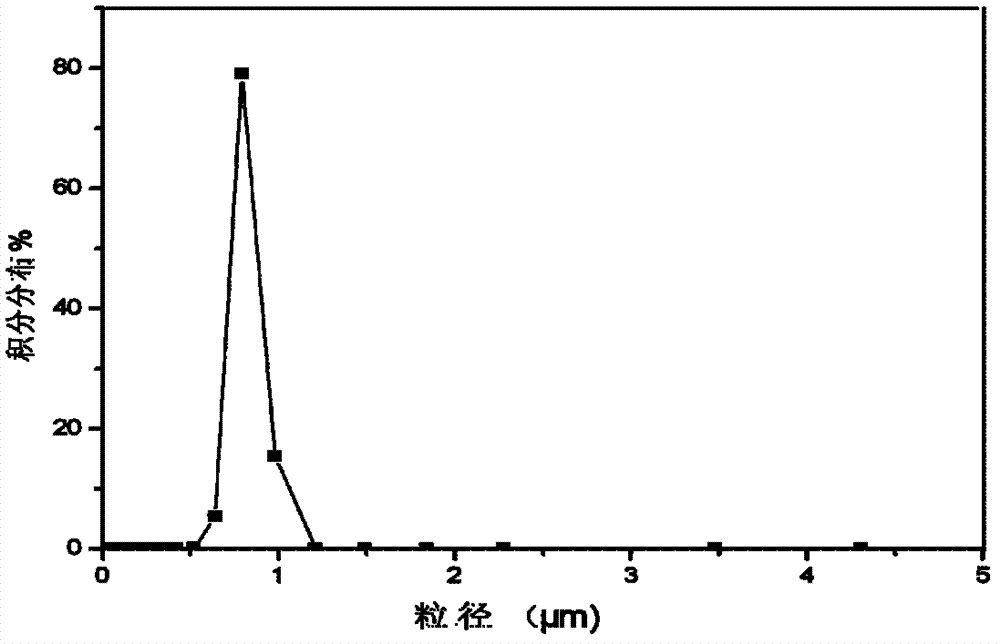

[0032] Weigh 15 grams of MnZn ferrite nanopowder, add 0.021 gram of vinyltriethoxysilane coupling agent (the mass of silicon element is 0.02% of the powder) into the powder, and carry out uniform stirring and mixing. Laser particle size analysis of the powder before and after adding the silane coupling agent, the results are as follows figure 1 , figure 2 shown. Depend on figure 1 It can...

Embodiment 2

[0038] The first step is to prepare MnZn ferrite nanopowder

[0039] MnZn ferrite nano-powder is prepared according to the method disclosed in patent CN101276668A, except that in this embodiment, after the black manganese-zinc ferrite nano-crystal is prepared, it is directly dried in an oven at 80°C to obtain a powder with an average particle diameter of 23nm. MnZn ferrite nanopowder, and its nominal chemical formula is Mn 0.5 Zn 0.5 Fe 2 o 4 .

[0040] The second step is to introduce the silane coupling agent

[0041] Weigh 15 grams of MnZn ferrite nanopowder, add 0.008 gram of vinyltrimethoxysilane coupling agent (silicon element mass is 0.01% of the powder) to the powder, stir and mix evenly, and carry out Press into tablets, and then use a mortar to grind into powder.

[0042] The third step, add binder and shape

[0043] Add polyethylene glycol (PEG) into the powder obtained in the second step in an amount of 3% of the mass of the powder, put it into a mortar and m...

Embodiment 3

[0047] The first step is to prepare MnZn ferrite nanopowder

[0048] MnZn ferrite nano-powder is prepared according to the method disclosed in patent CN101276668A, except that in this embodiment, after the black manganese-zinc ferrite nano-crystal is prepared, it is directly dried in an oven at 80°C to obtain a powder with an average particle diameter of 25nm. MnZn ferrite nanopowder, and its nominal chemical formula is Mn 0.6 Zn 0.4 Fe 2 o 4 .

[0049] The second step, doping and introducing silane coupling agent

[0050] Weigh 5 grams of MnZn ferrite nano-powder, add 0.001 gram of CaO white powder, and put them into a ball mill jar at a speed of 300 rad / min, and ball mill for 6 hours. Then add 0.009 g of vinyltrichlorosilane coupling agent (the mass of silicon element is 0.03% of the powder) into the powder. Then put into the ball mill jar, the rotating speed is 100rad / min, ball mill for 0.5 hour.

[0051] The third step, add binder and shape

[0052] Add polyvinyl b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com