Method for recovering alhumin from deposited components I+II+III from cold ethanol method

A low-temperature ethanol method, albumin technology, applied in the preparation methods of albumin peptides, serum albumin, peptides, etc., can solve the problem of low albumin extraction rate, improve the total yield, reduce production costs, improve quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

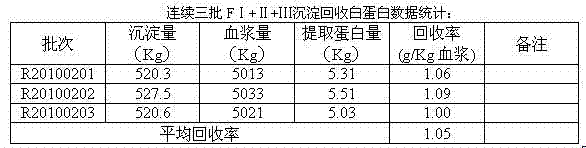

Image

Examples

Embodiment 1

[0029] (1) Preparation of F1 supernatant

[0030] Use 5 to 6 times the volume of water for injection to dissolve the precipitate of component I+II+III, stir at 1°C for 3 hours to completely dissolve it, add sodium dihydrogen phosphate to 0.01mol / L, and then add 0.2 mol / L sodium hydroxide to adjust the pH value to 4.95, slowly add ethanol with a volume fraction of 95% to make the volume concentration of ethanol in the solution reach 7.5%, and control the solution temperature to -4.5°C to cause F1 precipitation; after the F1 precipitation is completely produced Add perlite to 2.8g / L and diatomaceous earth to 2.8g / L, continue to stir to make the liquid into a slurry, press filter to separate the FI precipitate produced in the system, and obtain the FI supernatant;

[0031] (2) Preparation of FⅢ supernatant

[0032] Transfer the FⅠ supernatant from the previous step into a clean stainless steel reaction tank, add 0.2 mol / L sodium hydroxide to adjust the pH to 5.10, continue to ad...

Embodiment 2

[0046] (1) Preparation of F1 supernatant

[0047] Use: 6 times the volume of water for injection to dissolve the component I+II+III precipitate, stir at 5°C for 5 hours to completely dissolve it, add sodium dihydrogen phosphate to 0.01mol / L, adjust the pH value to 5.5, and slowly add The volume fraction of ethanol is 95% so that the volume concentration of ethanol in the solution reaches 8.5%, and the temperature of the solution is controlled between -2°C to cause F1 precipitation; after the F1 precipitation is complete, add perlite to 3.2g / L, silicon Alginate 3.2g / L, continue to stir to make the liquid into a slurry, press filter to separate the FI precipitate produced in the system, and obtain the FI supernatant;

[0048] (2) Preparation of FⅢ supernatant

[0049] Transfer the FⅠ supernatant from the previous step into a clean stainless steel reaction tank, adjust the pH value to 5.2, continue to add ethanol to a volume concentration of 14.5%, and control the liquid tempera...

Embodiment 3

[0063] (1) Preparation of F1 supernatant

[0064] Use 5.5 times the volume of water for injection to dissolve the precipitate of component I+II+III, stir at 3°C for 4 hours to dissolve completely, add sodium dihydrogen phosphate to 0.01mol / L, adjust the pH value to 5.00, and slowly add volume Ethanol with a fraction of 95% makes the volume concentration of ethanol in the solution reach 8.0%, and the temperature of the solution is controlled between -2.2°C to cause F1 precipitation; after the F1 precipitation is complete, add perlite to 3.0g / L, diatom Soil 3.0g / L, continue to stir to make the liquid into a slurry, press filter to separate the FI precipitate produced in the system, and obtain the FI supernatant;

[0065] (2) Preparation of FⅢ supernatant

[0066] Transfer the FⅠ supernatant from the previous step into a clean stainless steel reaction tank, adjust the pH value to 5.15, continue to add ethanol to a volume concentration of 14%, and control the liquid temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com