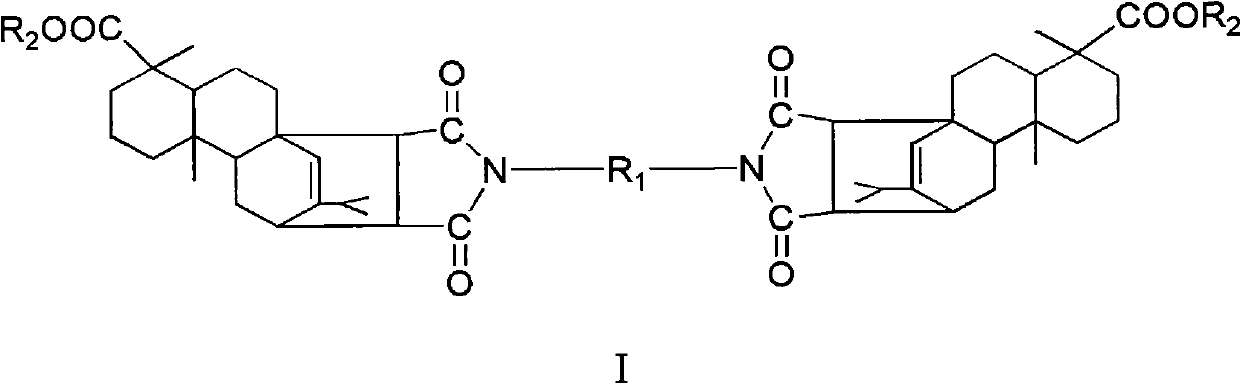

Rosinyl plasticizer and preparation method thereof

A plasticizer and rosin-based technology, applied in the field of rosin-based plasticizers and their preparation, can solve the problems of loss of performance, hardening, and brittle products, so as to prevent migration and exudation, easy operation, and improve migration resistance and the effect of anti-seepage performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

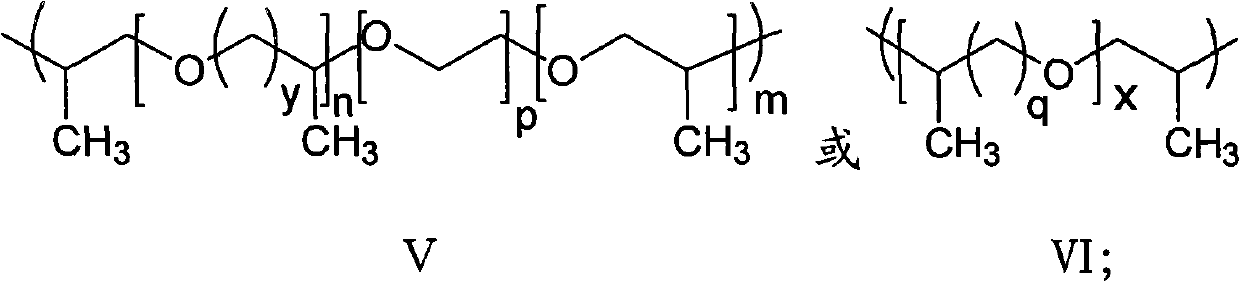

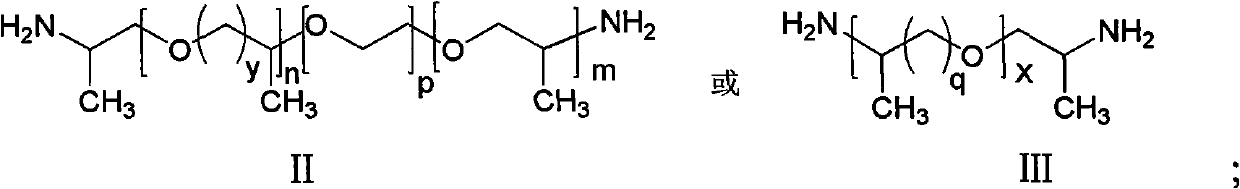

[0045] (1) Under nitrogen protection, dissolve 100 parts by weight of maleopimaric anhydride in 90 parts by weight of DMF, heat to 90°C, and add 110 parts by weight of toluene and 28 parts by weight of the formula III with a number average molecular weight of 230 The end group of the structure is a polyether of amino group (wherein, x is a positive integer of 1 to 4, and q is 1). After reacting at 90°C overnight, raise the temperature to 120°C, react for 9 hours, cool to room temperature, and pour the reaction solution into water, extracted with ether, washed with water, and dried in vacuum to obtain 98 parts by weight of polyether whose end group is abietic acid.

[0046] (2) Put the above-mentioned 98 parts by weight of polyether whose pine end group is abietic acid into a reaction kettle with a thermometer, nitrogen protection and a sampling tube, add 50 parts by weight of n-butanol and 2.5 parts by weight of zinc oxide, and carry out at 220 ° C. Reflux esterification react...

Embodiment 2

[0055] (1) Under nitrogen protection, dissolve 100 parts by weight of maleopimaric anhydride in 90 parts by weight of DMSO, heat to 90°C, and add 120 parts by weight of benzene and 250 parts by weight of the formula II with a number average molecular weight of 2000. The terminal group of the structure is a polyether of amino groups (wherein, p is a positive integer of 20 to 45, m and n are both positive integers of 1 to 6, y is 1, and various combinations of p, m, n, y make The number average molecular weight of this polyether is 2000), after reacting overnight at 90°C, raise the temperature to 110°C, react for 12 hours, cool to room temperature, pour the reaction solution into water, extract with ether, wash with water, and dry in vacuum to obtain 236 parts by weight A polyether end-grouped with abietic acid.

[0056] (2) Put the above-mentioned 236 parts by weight of polyether whose end group is abietic acid into a reaction kettle with a thermometer, nitrogen protection and ...

Embodiment 3

[0065] (1) Under nitrogen protection, dissolve 100 parts by weight of maleopimaric anhydride in 90 parts by weight of acetone, heat to 90°C, and add 110 parts by weight of toluene and 110 parts by weight of the formula II with a number average molecular weight of 900 The terminal group of the structure is a polyether of amino groups (wherein, p is a positive integer of 8 to 15, m and n are both positive integers of 1 to 6, y is 1, and various combinations of p, m, n, y make The number average molecular weight of this polyether is 900), after reacting overnight at 90°C, raise the temperature to 140°C, react for 12 hours, cool to room temperature, pour the reaction solution into water, extract with ether, wash with water, and dry in vacuum to obtain 168 parts by weight A polyether end-grouped with abietic acid.

[0066] (2) above-mentioned 168 weight parts end groups are that the polyether of abietic acid drops in the reactor that has thermometer, nitrogen protection and samplin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com