Method for extracting zinc indium and recovering iron from high-iron high indium zinc concentrate

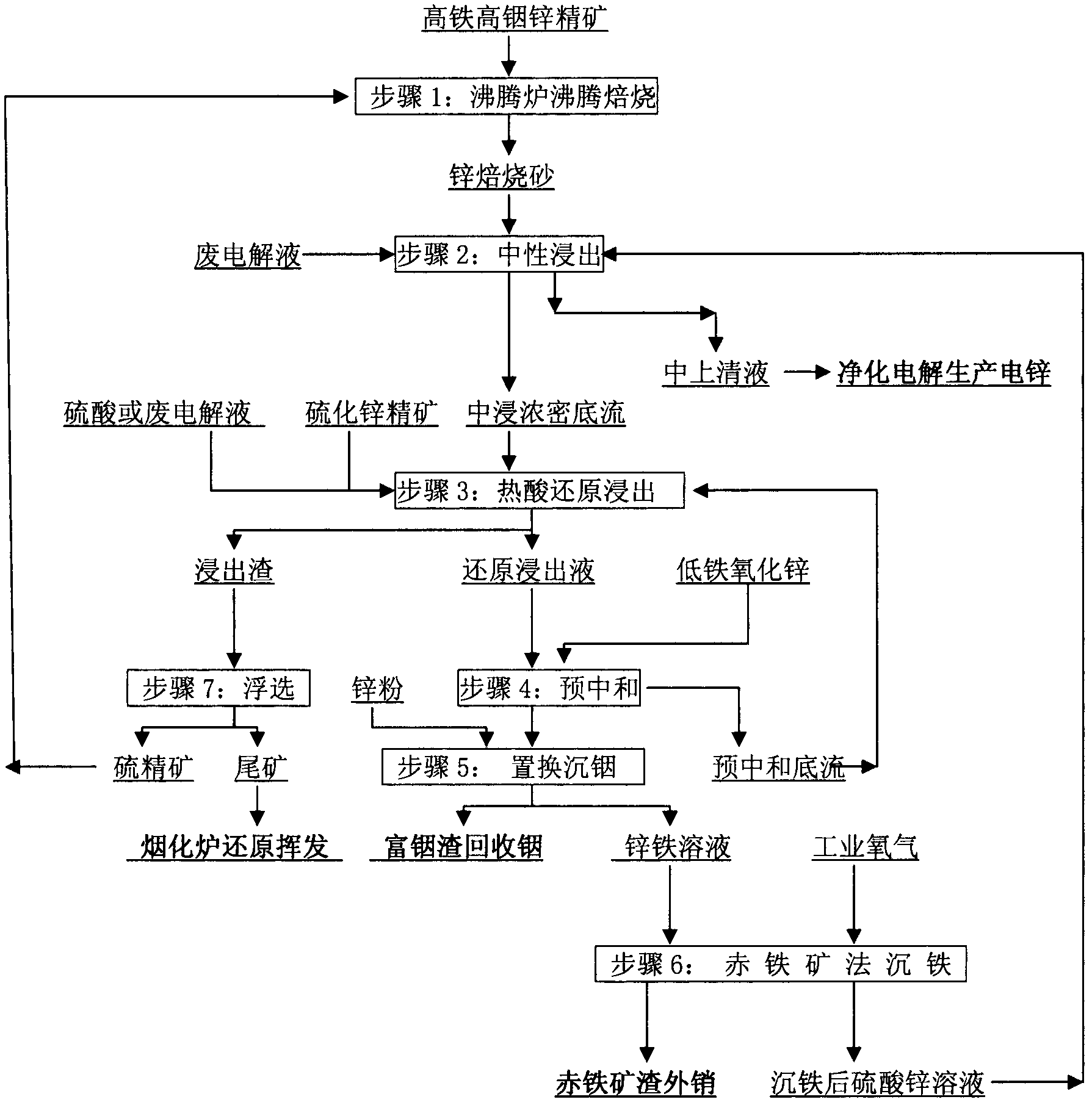

A technology for recovering iron from zinc concentrate is applied in the fields of extracting zinc indium and recovering iron from high iron and high indium zinc concentrate, which can solve the problems of low recovery rate of indium smelting, large amount of jarosite slag and high production cost, and achieves the realization of The effect of resource utilization, high recovery rate and efficient recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The zinc concentrate containing 13.6% iron, 0.055% indium, and 44% zinc is roasted at medium temperature in a fluidized fluidized furnace at a roasting temperature of 920-940°C, and the produced zinc calcine or zinc fume contains 46.8% zinc.

[0022] Add 22 cubic meters of waste electrolyte containing 150g / L of sulfuric acid and 50g / L of zinc and 87 cubic meters of liquid after sinking iron containing 119g / L of zinc and 45g / L of acid in said zinc calcine or zinc smoke dust, Neutrally leaching 10 tons of zinc calcine containing 46.8% zinc, the temperature is 60-70°C, the leaching time is 1.5 hours, and the pH of the leaching end point is 5.4; 83 cubic meters of supernatant solution containing 149g / L zinc is produced, and zinc After the powder is purified, it is electrolyzed to produce electrolytic zinc, and at the same time, 29 cubic meters of dense underflow in the middle immersion is produced.

[0023] Add 68 cubic meters of waste electrolyte containing 150g / L sulfuric...

Embodiment 2

[0029] The zinc concentrate containing 14.8% iron, 0.092% indium, and 47% zinc is roasted at medium temperature in a fluidized fluidized furnace at a roasting temperature of 910-940°C, and the produced zinc calcine or zinc fume contains 49.2% zinc.

[0030] Add 8 cubic meters of waste electrolyte containing 156g / L of sulfuric acid and 46g / L of zinc and 30 cubic meters of liquid after sinking iron containing 129g / L of zinc and 25g / L of acid in said zinc calcine or zinc smoke dust, Neutral leaching of 3.8 tons of zinc calcine or zinc fume containing 49.2% zinc, temperature 55-65 ° C, leaching time 2.0 hours, leaching end point pH = 5.4; output 29 cubic meters of supernatant solution containing zinc 146g / L , adding zinc powder for purification and electrolysis to produce electrolytic zinc, and at the same time produce 10 cubic meters of dense underflow in the middle immersion.

[0031] Add 24 cubic meters of waste electrolyte containing 150g / L of sulfuric acid and 50g / L of zinc a...

Embodiment 3

[0037] The zinc concentrate containing 19.8% iron, 0.25% indium, and 48% zinc is roasted at medium temperature in a fluidized fluidized furnace at a roasting temperature of 930-950°C, and the produced zinc calcine or zinc fume contains 51.2% zinc.

[0038] Add 11 cubic meters of waste electrolyte containing 150g / L of sulfuric acid and 50g / L of zinc and 43 cubic meters of liquid after sinking iron containing 119g / L of zinc and 45g / L of acid in said zinc calcine or zinc smoke dust, Neutral leaching of 5 tons of zinc calcined sand containing 51.2% zinc was carried out at a temperature of 65-70°C, leaching time of 1.5 hours, and pH of the leaching end point = 5.2; 41.5 cubic meters of supernatant solution containing 150 g / L of zinc was produced, and at the same time A dense underflow of 14.5 cubic meters is produced.

[0039] Add 34 cubic meters of waste electrolyte containing 157g / L of sulfuric acid and 45g / L of zinc and 1.5 tons of high-iron and high-indium-zinc concentrate to 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com