Relaxation SiGe virtual substrate and preparation method thereof

A substrate and relaxation technology, used in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problems of complex process, large thickness of SiGe virtual substrate, rough surface, etc., to achieve low dislocation density, shorten the Epitaxy time, the effect of surface flattening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

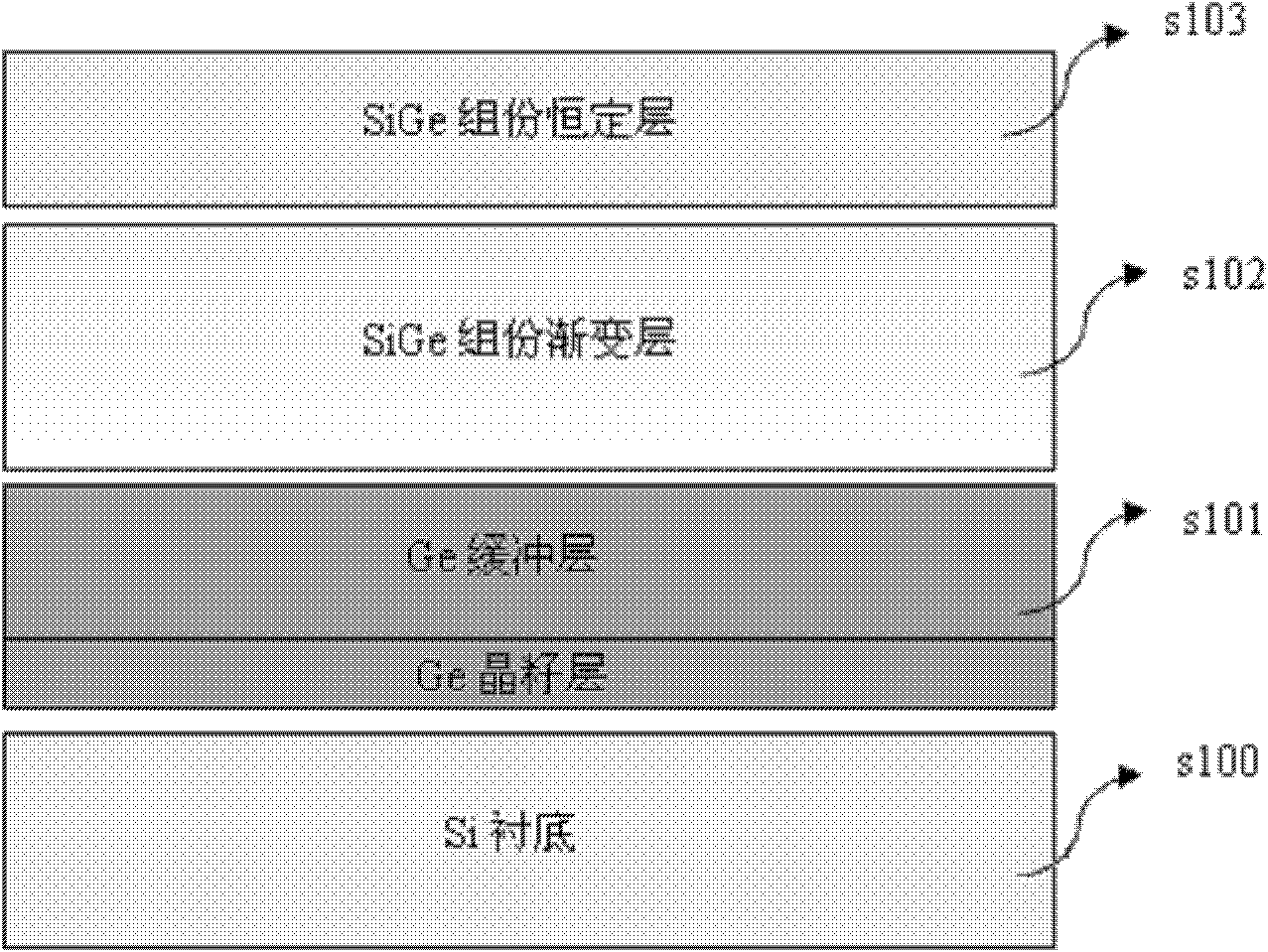

[0043] The preparation process of a SiGe dummy substrate with high germanium content is as follows: figure 1 shown to prepare Si 0.2 Ge 0.8 Taking the virtual substrate as an example, it includes the following steps:

[0044] In step s100, four 4-inch, 6-inch, 8-inch and 12-inch Si wafers are respectively prepared as Si substrates.

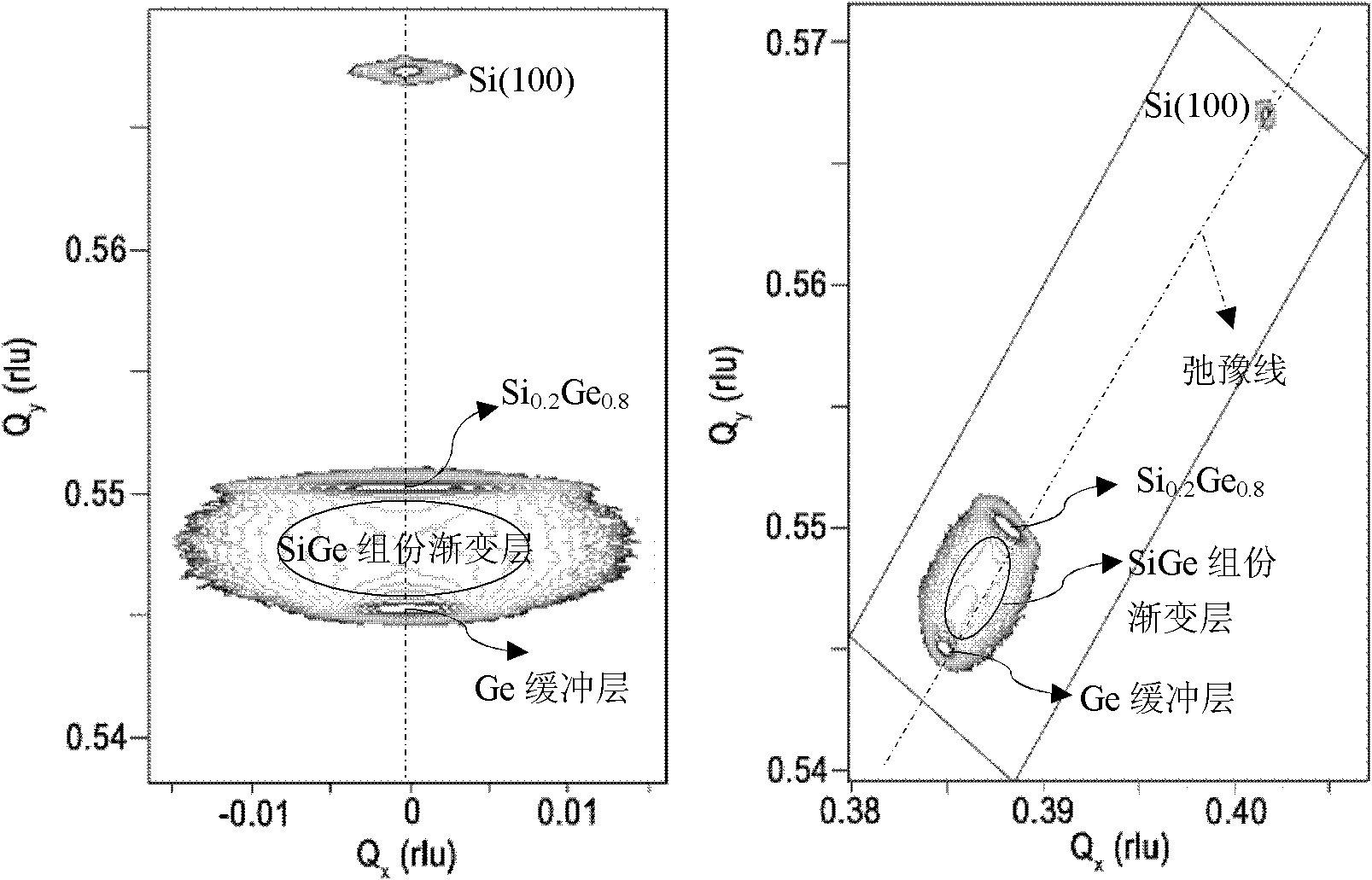

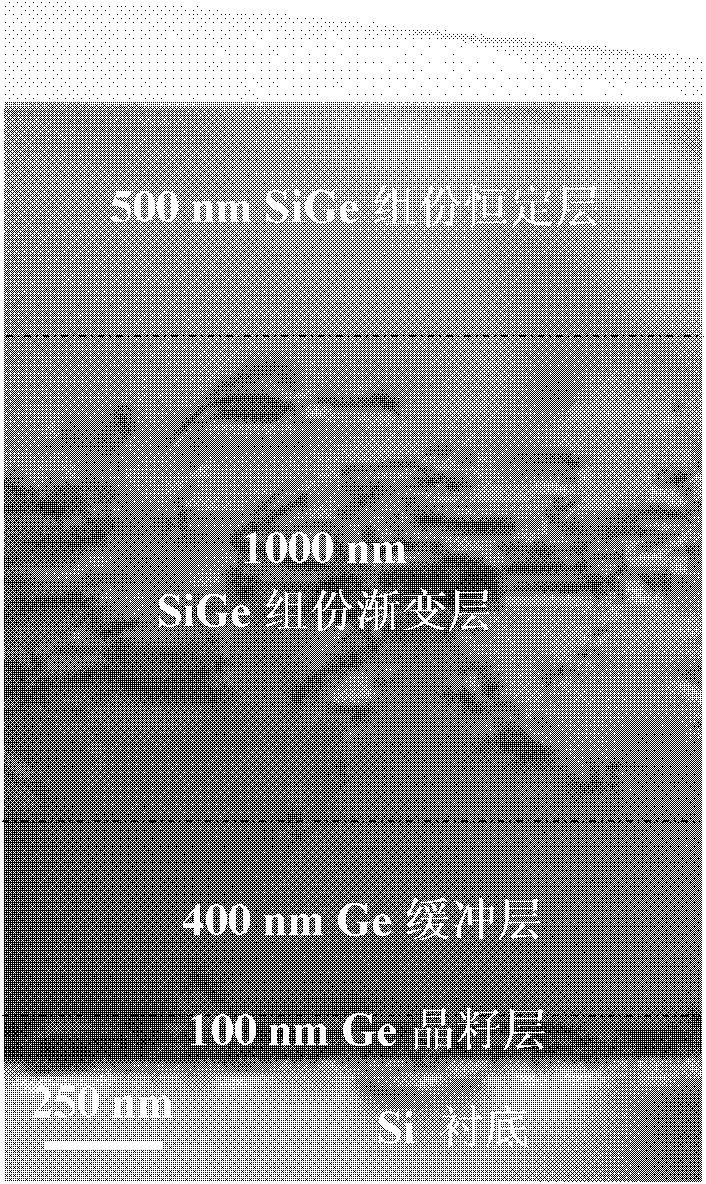

[0045] Step s101, growth of Ge relaxation buffer layer: based on 4-inch, 6-inch, 8-inch and 12-inch Si substrates, respectively, at 400 ° C with GeH 4 is the gas phase precursor, GeH 4 The flow rate is 150sccm, in H 2 As the carrier gas, the pressure in the growth chamber is 100Torr, and a Ge seed layer with a thickness of 50nm, 60nm, 100nm, and 100nm is deposited respectively; the growth atmosphere is kept constant, and then on the deposited four Ge seed layers at 700 Deposit Ge buffer layers with a thickness of 300nm, 340nm, 400nm and 600nm respectively at ℃, and anneal in situ (epitaxial growth chamber) at 850℃ for 10 minutes after complet...

Embodiment 2

[0054] A Si with high germanium content 0.15 Ge 0.85 The preparation of virtual substrate comprises the following steps:

[0055] In step s100, an 8-inch Si wafer is prepared as a Si substrate.

[0056] Step s101, growth of the Ge relaxation buffer layer: on the basis of an 8-inch Si substrate, at 350 ° C with GeH 4 is the gas phase precursor, GeH 4 The flow rate is 200sccm, in H 2 As the carrier gas, the growth chamber pressure is 100Torr, deposit a layer of Ge seed layer with a thickness of 100nm; keep the growth atmosphere unchanged, and then deposit a Ge buffer layer with a thickness of 400nm on the deposited Ge seed layer at 650°C, After completion, in-situ (epitaxial growth chamber) annealing at 850° C. for 10 minutes, maintaining the growth chamber pressure at 100 Torr during annealing, to obtain a Ge relaxation buffer layer with a thickness of 500 nm and complete strain relaxation.

[0057] Step s102, growth of a composition-graded SiGe buffer layer: on the basis ...

Embodiment 3

[0065] A Si with high germanium content 0.1 Ge 0.9 The preparation of virtual substrate comprises the following steps:

[0066] In step s100, a 6-inch Si wafer is prepared as a Si substrate.

[0067] Step s101, growth of the Ge relaxation buffer layer: on the basis of a 6-inch Si substrate, first at 400 ° C with GeH 4 is the gas phase precursor, GeH 4 The flow rate is 100sccm, in H 2 As the carrier gas, the growth chamber pressure is 50Torr, deposit a layer of Ge seed layer with a thickness of 100nm; keep the growth atmosphere unchanged, and then deposit a Ge buffer layer with a thickness of 500nm on the deposited Ge seed layer at 650°C, After completion, in-situ (epitaxial growth chamber) annealing at 800° C. for 10 minutes, while maintaining the pressure of the growth chamber at 100 Torr during annealing, obtained a Ge relaxation buffer layer with a thickness of 600 nm and complete strain relaxation.

[0068] Step s102, growth of a composition-graded SiGe buffer layer: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com