Preparation of ZnSnS film and ZnSnS/SnS heterojunction, and application of solar cells

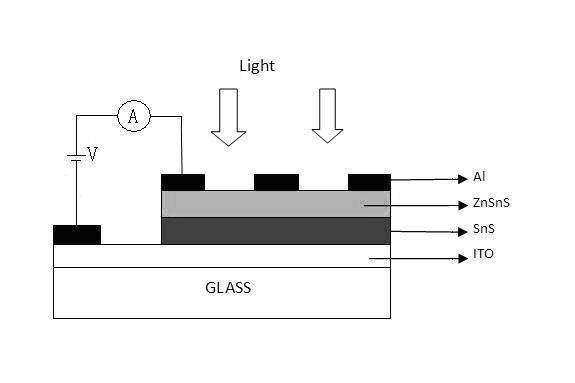

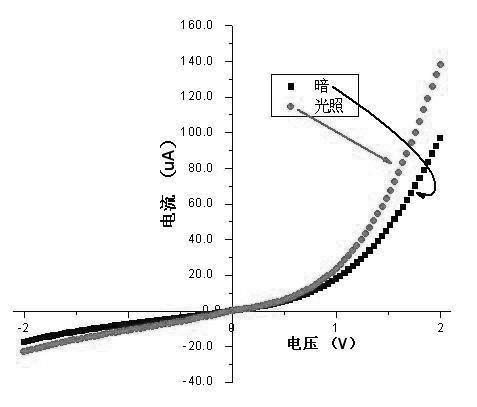

A heterojunction and thin film technology, applied in the field of solar cell materials, can solve the problems of increased preparation process and cost, thin film looseness and poor uniformity, and preparation of ZnSnS thin film, so as to avoid structural damage and performance degradation, and the equipment and preparation process are simple , rich effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] By studying the electrodeposition preparation of materials such as SnS and ZnS, a method for growing ZnSnS thin films in one step is obtained. The specific process is as follows:

[0026] 1) Cleaning: Cleaning directly affects the quality of the thin film material obtained. The ITO substrate, platinum wire, reference electrode, beaker, etc. used are all cleaned by the following methods. Ultrasonic cleaning in washing liquid for 10 minutes first, then rinsing with deionized water, ultrasonic cleaning in deionized water for 10 minutes, and finally ultrasonic cleaning in absolute alcohol for 10 minutes.

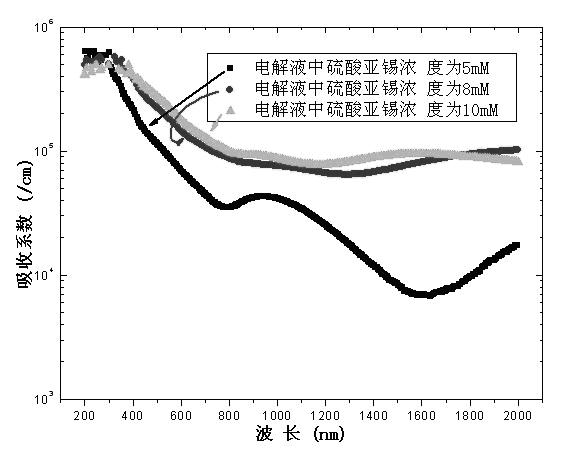

[0027] 2), preparation of electrolyte: sodium thiosulfate is 100mM, zinc sulfate is 30mM (25-35mM is also acceptable), the concentration of stannous sulfate (from 0-10mM) can be adjusted to prepare different Sn component ratios film, and then adjust the pH of the solution to 3.0 by dropping dilute sulfuric acid. The stannous sulfate can also be 0, then it is a pure ZnS ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com