Agranular transparent conductive ink and its preparation method

A transparent conductive, particle-free technology, applied in the direction of copying/marking methods, inks, printing, etc., can solve problems such as changes, impacts on use, and demanding printing substrates, and achieve low preparation costs, wide range of printing substrates, and inks effect of transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 30g of sodium citrate was dissolved in 100ml of water, 52g of silver nitrate was dissolved in 150ml of water, then, the resulting silver nitrate aqueous solution was slowly added to the aqueous solution of sodium citrate, stirred at room temperature for one hour, filtered, washed with deionized water 3 times, ethanol After washing once, place it in a dark room at 30°C to dry naturally to obtain silver-white citrate powder.

[0033] Mix 5ml of methanol, 2ml of 1,2-propylenediamine and 3ml of isopropanol evenly, keep the temperature at 5°C, then add 2.0g of silver citrate, stir at 5°C for 1h, pass the obtained colorless and transparent solution through 0.45μm After filtering with a filter membrane, the silver citrate-based ink-jet printing conductive ink is obtained.

[0034] The viscosity of the ink measured at 25°C with the Brookfield DV-II+Pro viscosity tester is 5.27cP, using The DSA-20 dynamic contact angle measuring instrument measured the surface tension of the ink...

Embodiment 2

[0036] The preparation method of silver acetate solid powder is as the preparation method of silver citrate among the embodiment one.

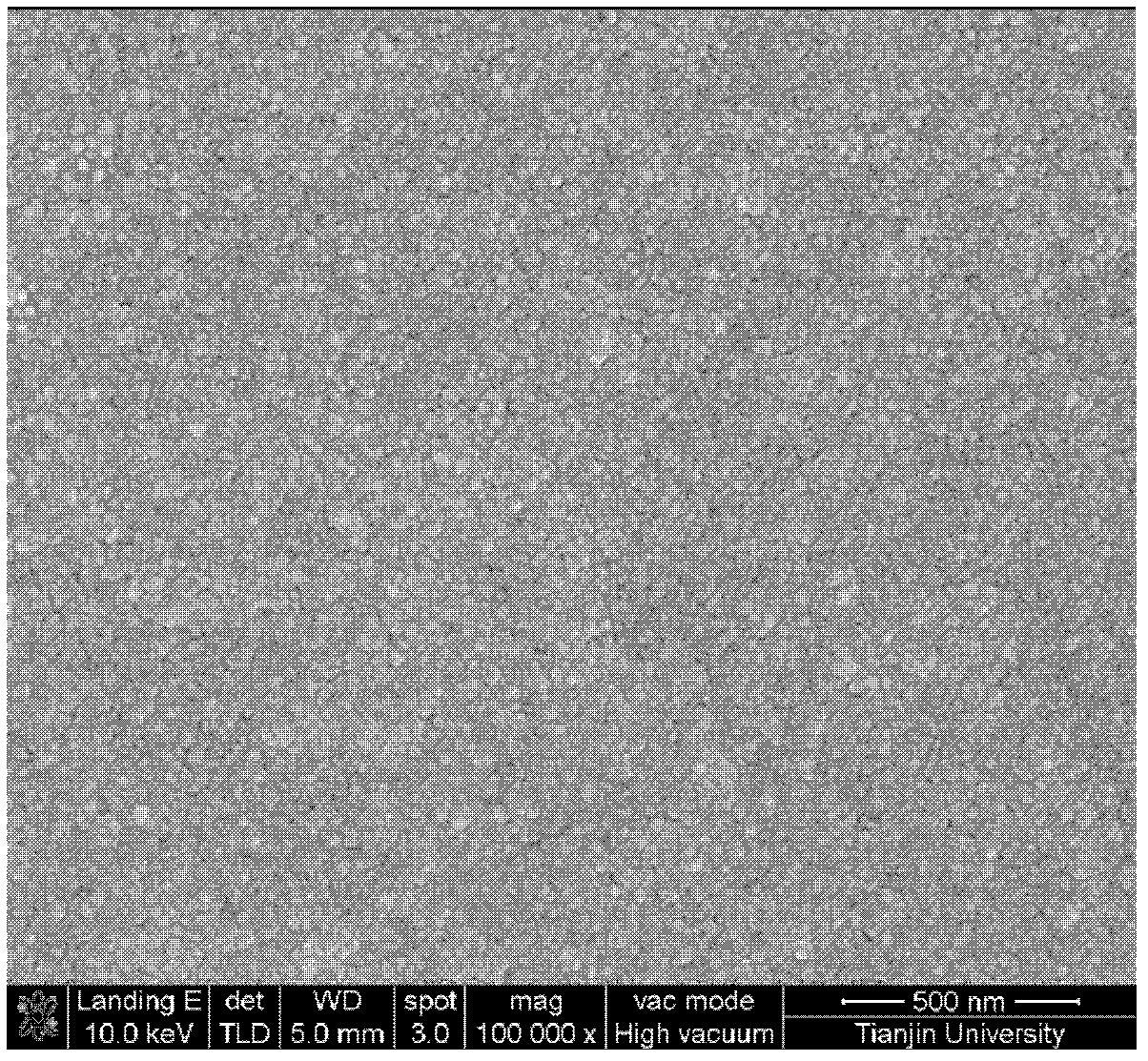

[0037] Dissolve 4.0g of silver acetate in a mixed solvent composed of 3ml of ethanol, 4ml of ethylenediamine and 3ml of ethylene glycol, and stir at 5°C for 1h to obtain a slightly yellow, transparent solution, which is passed through a 0.45μm filter membrane, That is, silver acetate-based conductive ink is obtained. The viscosity of the ink measured at 25°C is 30cP, and the surface tension is 38mN·m -1 , printed on EPSON photo paper using a gravure printing proofing machine, treated at 130°C for 10 minutes, the square resistance measured by a four-probe resistance tester was 0.06Ω / □, and the SEM photo of the obtained conductive pattern is attached to the instruction manual image 3 .

Embodiment 3

[0039] Mix 2ml of n-butanol, 6ml of ethylenediamine and 2ml of ethylene glycol evenly, keep the temperature at 5°C, then add 17g of silver citrate, and stir for 2 hours at a constant temperature. After treatment at 200° C. for 2 minutes, the sheet resistance value of the obtained conductive pattern is 0.005Ω / □ (sheet resistance unit).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com