Method for preparing biological carbon through high pressure liquefaction of biomass

A biomass and bio-carbon technology, applied in the preparation of liquid hydrocarbon mixtures, petroleum industry, etc., can solve problems such as by-product residues, and achieve the effects of reducing environmental pollution, low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

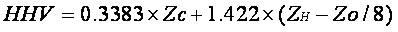

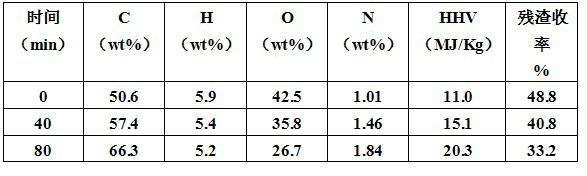

[0026] Dry the corn stalks to a moisture content of 8%, and crush them to a fineness of 40 meshes. Add 10 g of crushed corn stalks and 100 mL of ethanol to a batch-type high-temperature and high-pressure reactor (PARR Company, USA, volume 1 L) for liquefaction reaction. Heating at room temperature to 300°C, the reaction time is 0, 40 and 80 minutes respectively, and the reaction pressure is 1 to 7 MPa, and the liquefied product is obtained after the completion of the reaction; the liquefied product is dissolved in water and washed to separate the water-soluble product, and the water-insoluble product is used Acetone washes the organic soluble product at the separation, and the remaining insoluble solid is biochar.

[0027] The specific separation process is as follows: after vacuum distilling off the residual ethanol in the liquefied product at 70°C, add 150 mL of deionized water to the remaining residue to extract water-soluble organic matter and water-insoluble residue, and ...

Embodiment 2

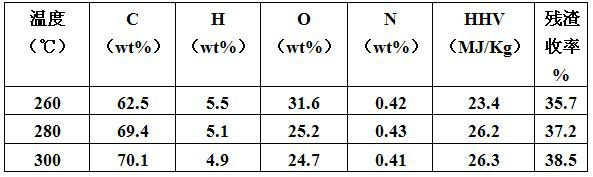

[0035] Dry the cypress to a moisture content of 6%, and crush it to a fineness of 40 meshes. Get 10 g of pulverized cypress powder and 100 mL of water into the same batch-type high-temperature and high-pressure reactor as in Example 1, and heat the reactor so that the temperature rises to 260 ° C, 280 ° C and 300 ° C respectively, and the reaction pressure is respectively 4.9 MPa, 6.6MPa and 10.2MPa, the separation process is the same as that in Example 1. Table 2 shows the change data of residue yield and biochar elements (C, H, N, O) with temperature under the action of high-pressure hot water of cypress powder, and the calculation method is the same as that of Example 1. The mass percentages of biological carbon elements C, H, N, and O in the raw materials were 48.87, 5.99, 0.3, and 44.84 (wt%), respectively, and the calorific value was 17 MJ / Kg. Table 2 shows that after the cypress is liquefied with high-pressure hot water, the calorific value of the residue is as high as...

Embodiment 3

[0039] The cypress raw material is the same as that used in Example 2, and the cypress is dried to a water content of 10%, and crushed to a fineness of 40 meshes. Get 10 g of pulverized cypress powder and 100 mL of water into the same batch-type high-temperature and high-pressure reactor as in Example 1, heat the reactor so that the temperature rises to 260° C., and the reaction stays at 260° C. for 10 minutes , 20 minutes, 30 minutes and 40 minutes, the reaction pressure is 4 to 6MPa, and the separation process is the same as the process in Example 1.

[0040] Table 3 shows the change data of residue yield and bio-carbon elements (C, H, N, O) with reaction time at 260°C. The calculation method is the same as that in Example 1. When the time reaches 30 to 40 minutes, it is as high as 26.2MJ / Kg, and when the reaction is 40 minutes, the heat value of the residue yield is as high as 37.8%.

[0041] table 3

[0042]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Calorific value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com