Method for measuring magnetostriction constant by using multi-beam laser heterodynes

A technology of magnetostriction coefficient and laser heterodyne, applied in the direction of magnetostriction performance measurement, measurement device, magnetic performance measurement, etc., can solve the problem of low precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

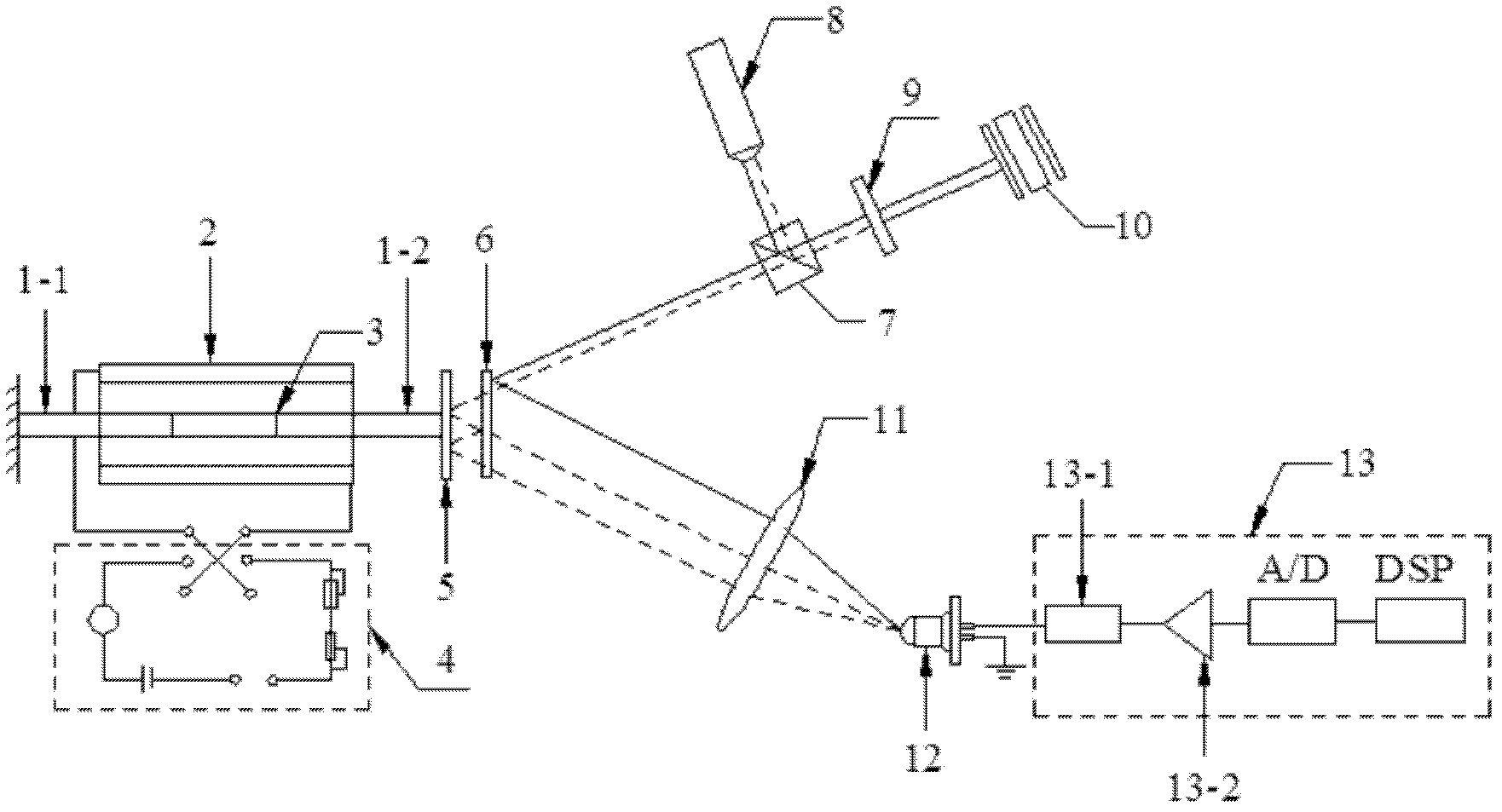

[0061] Specific Embodiment 1. The method for measuring hysteresis coefficient by multi-beam laser heterodyne described in this embodiment is realized based on the following device, which can be found in figure 1 As shown, the device includes two fixed rods 1-1, 1-2 of the same shape, excitation coil 2, DC stabilized power supply 4, plane mirror 5, thin glass plate 6, polarizing beam splitter PBS7, H 0 Solid-state laser 8, quarter-wave plate 9, vibrating mirror 10, converging lens 11, photodetector 12 and signal processing system 13,

[0062] The DC stabilized power supply 4 is used to provide working power to the excitation coil 2, so that the excitation coil 2 generates a magnetic field, the test piece 3 is placed in the center in the cylindrical space formed by the excitation coil 2, and one end of the test piece 3 is fixedly connected to a One end of the fixed rod 1-1, the other end of the fixed rod 1-1 is fixed, the other end of the test piece 3 is fixed to one end of anot...

specific Embodiment approach 2

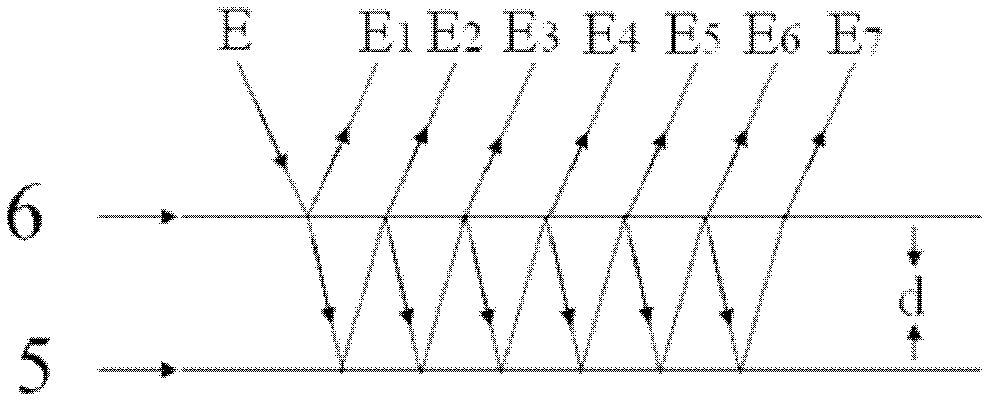

[0079] Specific embodiment two, this embodiment is a further limitation of the method for multi-beam laser heterodyne measurement of the hysteresis coefficient described in specific embodiment one, in this embodiment, according to the electrical signal output by the photodetector 12 to obtain the The process of the length variation Δl of the part 3 is: the photocurrent signal sent by the photodetector 12 received by the signal processing system 13 is I, and the expression of the photocurrent signal I is:

[0080] I = ηe hv 1 Z ∫ ∫ S 1 2 [ E 1 ( t ) + E 2 ( t ) + · · · + ...

specific Embodiment approach 3

[0118] Specific implementation mode three, this implementation mode is a specific embodiment of the method for multi-beam laser heterodyne measurement of hysteresis expansion coefficient according to the present invention:

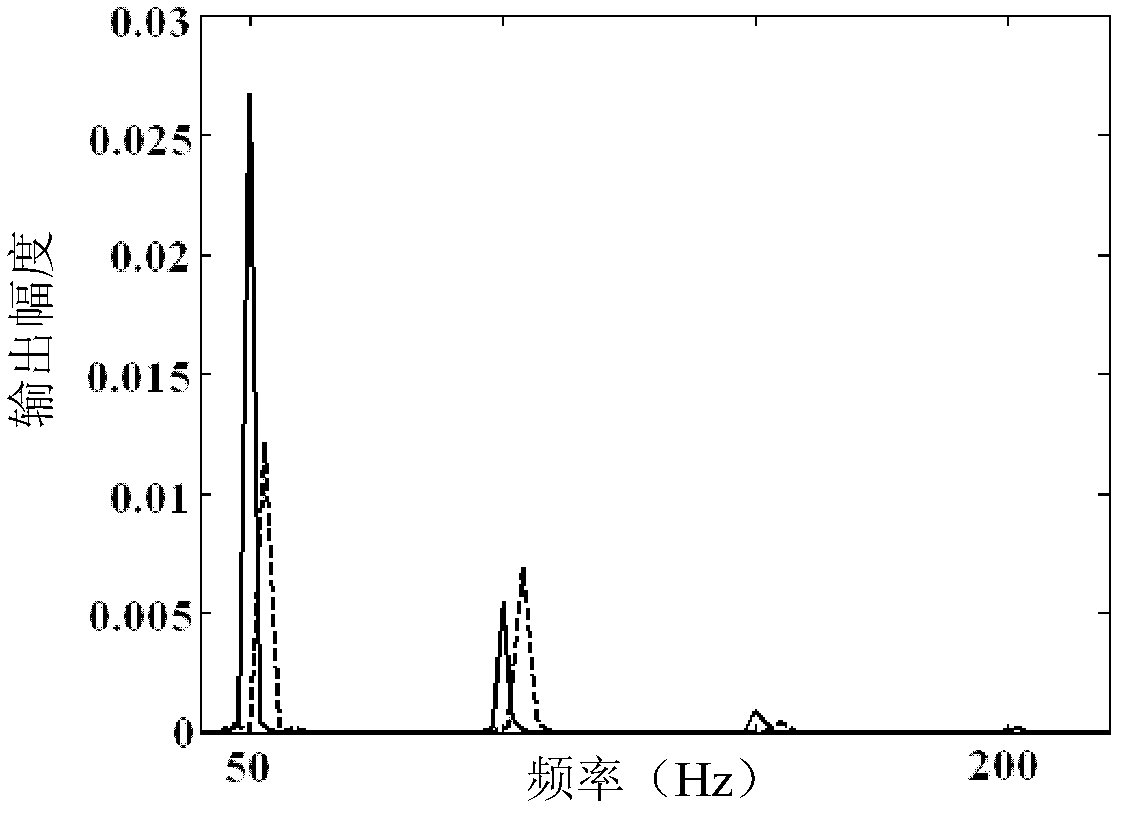

[0119] In this embodiment, MATLAB is used to simulate and measure the magnetostriction coefficient of a 200 mm-long iron-nickel alloy sample thin glass plate. H used o The wavelength λ=2050nm of the laser light that solid-state laser device 8 sends; Exciting coil 2 is 200 turns / cm; The refractive index of medium between plane mirror 5 and thin glass plate 6 gets n=1; =1mm, the sensitivity of the detector 12 is 1A / W. The vibration equation x(t)=a(t of the vibrating mirror 10 2 / 2), take a=2×10 3 m / s 2 . During the experiment, it was ensured that the current applied to the exciting coil 2 would not be magnetically saturated.

[0120] It can be seen from the simulation that the Fourier transform spectrum of the multi-beam laser heterodyne signal obtaine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com