Polymer composite micro-bead and preparation method thereof

A technology of polymers and microbeads, which is applied in the direction of microsphere preparation, microcapsule preparation, chemical instruments and methods, etc., can solve the problems that the particle size of droplets cannot be precisely controlled, the internal structure cannot be obtained, and the structure of complex microbeads, etc., to achieve The effect of low equipment requirements, low cost, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

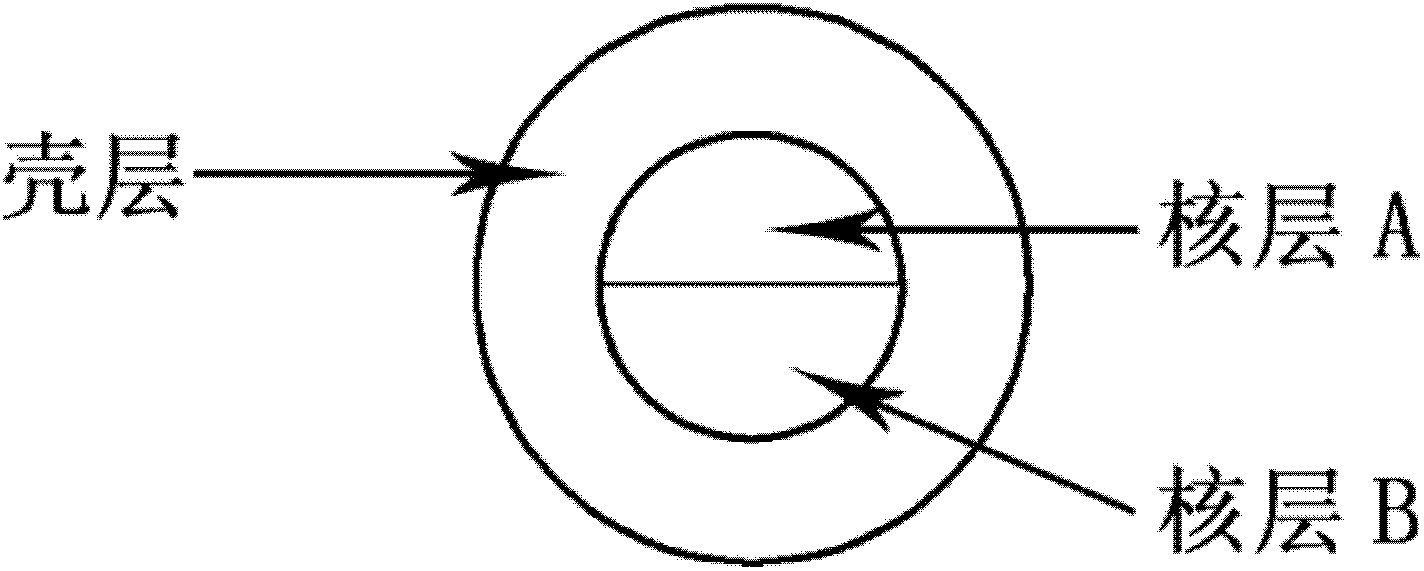

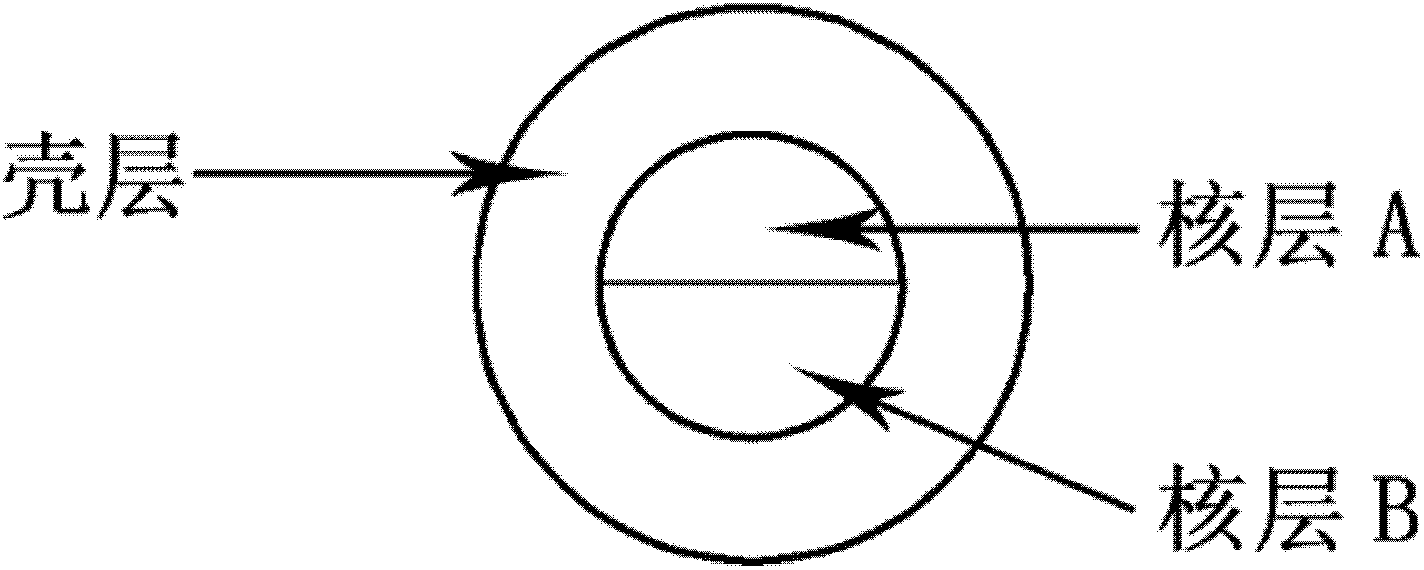

[0029] 2% sodium polystyrene sulfonate aqueous solution and 2% chitosan acetic acid / water solution are used as core layers A and B respectively, 5% polylactic acid / methylene chloride is used as shell layer, and the speed ratio of core layer and shell layer is 1 : 2, the water and shell velocity ratio is 30: 1, the diameter of the microtube is 300 microns, the diameter of the microbeads obtained is 200 microns, the core layer is 80 microns, each microbead contains 3 cores, and the shell layer is solidified by solvent volatilization.

Embodiment 2

[0031] 2% sodium hydroxymethyl cellulose aqueous solution and 2% polyacrylamide aqueous solution are used as core layers A and B respectively, 3% polyethylene / white oil solution is used as shell layer, and the speed ratio of core layer and shell layer is 1:5. The velocity ratio of water and the shell layer is 1:1, the diameter of the microtube is 2 mm, the diameter of the obtained microbead is 1.5 mm, and the core layer is 1 mm. Each microbead contains a core, and the shell layer is solidified by solvent extraction. Different drugs are added to the two core layers respectively to obtain drug sustained-release microbeads.

Embodiment 3

[0033] A 5% polyvinylpyrrolidone ethanol solution and a 4% polyvinyl alcohol aqueous solution are used as core layers A and B respectively, silicone oil is used as a shell layer, and toluene diisocyanate is added to the shell layer as a film-forming agent. The velocity ratio of the core layer and the shell layer is 1:10, the velocity ratio of water and the shell layer is 100:1, the diameter of the microtube is 500 microns, the diameter of the obtained microbeads is 400 microns, the core layer is 150 microns, and each microbead contains 1 nuclear. The core layer has two components, one component is added with ferric oxide powder and the other is added with titanium dioxide powder or water-soluble dye to obtain magnetically responsive chromogenic microspheres.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com