Preparation method for scale-controllable silicon nitride nano wire short-wavelength light emitting material

A silicon nitride nanometer and short-wavelength technology, applied in chemical instruments and methods, nitrogen compounds, nanotechnology, etc., can solve the problems of inapplicability to industrial production, difficulty in precise control of the scale, and low yield of nanowires, etc., and achieve uniform scale The effect of controllability, convenient operation and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Put nano silicon powder (with a grain size of 35nm) into a stainless steel heat preservation tank and immerse it in liquid nitrogen to keep the liquid level stable. The pretreatment time is 12 hours; transfer the heat preservation tank to a vacuum glove box and place it for 12 hours. Collect the prepared nano silicon powder. Put the prepared nano silicon powder in the corundum ark, put it into a vertical high temperature tube furnace, and pass a mixed gas of nitrogen and ammonia as the nitriding gas. The volume ratio of nitrogen and ammonia is 10:0, and the atmosphere The flow rate is 500 ml / min, the temperature is increased to 1300°C at a temperature increase rate of 10°C / min, the temperature is kept for 6 hours, and then cooled to room temperature. The silicon nitride nanowires are collected. The diameter of the silicon nitride nanowires is 40nm and the length is 20μm.

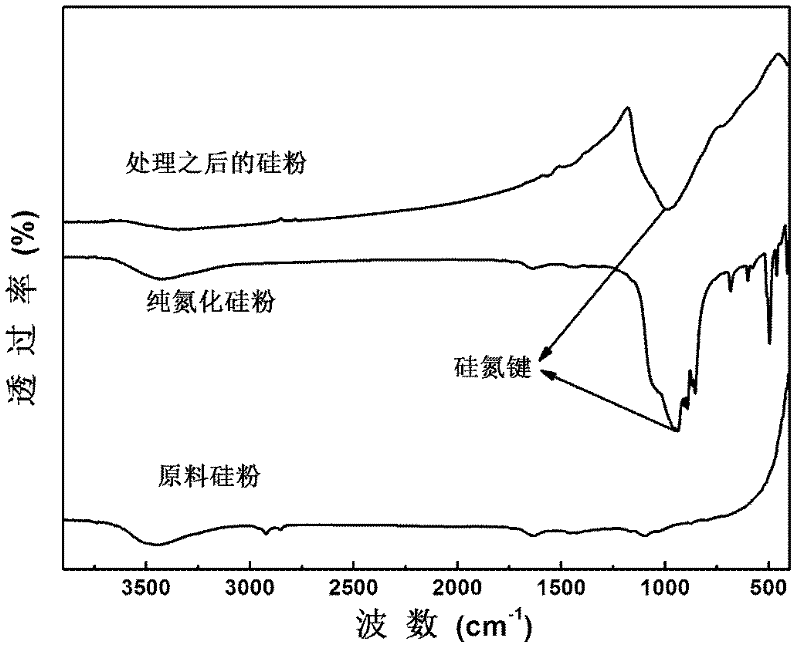

[0034] by figure 1 It can be seen that, in this embodiment, after the nano silicon powder is pretrea...

Embodiment 2

[0037] Put nano silicon powder (grain size of 30nm) into a stainless steel heat preservation tank and immerse it in liquid nitrogen to keep the liquid level stable. The pretreatment time is 60 hours; transfer the heat preservation tank to a vacuum glove box and place it for 18 hours. Collect the prepared nano silicon powder. Place the prepared nano silicon powder in a corundum ark, put it into a vertical high-temperature tube furnace, and pass a mixed gas of nitrogen and ammonia as the nitriding gas. The volume ratio of nitrogen to ammonia is 5:5. The flow rate is 200 ml / min, the temperature is increased to 1400°C at a heating rate of 8°C / min, the temperature is kept for 4 hours, and then cooled to room temperature. The silicon nitride nanowires are collected. The diameter of the silicon nitride nanowires is 33nm and the length is 15μm.

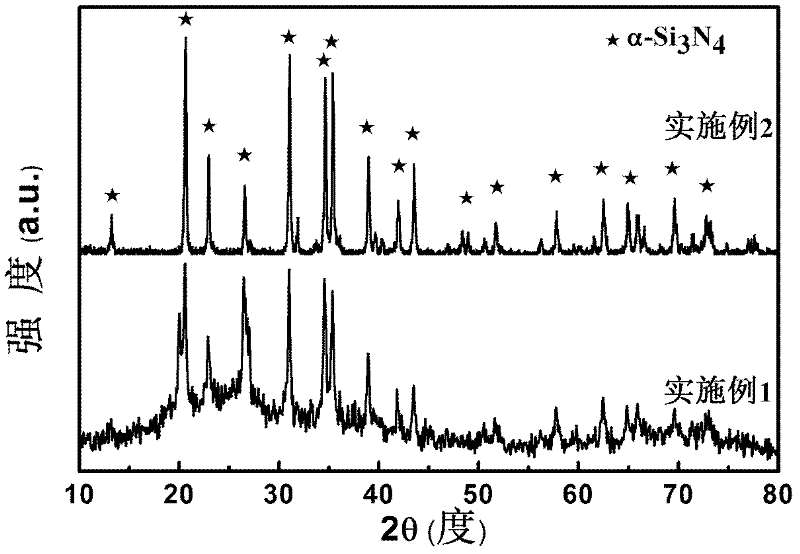

[0038] by figure 2 It can be seen that the main phase of the final product obtained in this example is α-Si 3 N 4 .

Embodiment 3

[0040] Put nano silicon powder (grain size of 20nm) into a stainless steel heat preservation tank and immerse it in liquid nitrogen to keep the liquid level stable. The pretreatment time is 80 hours; transfer the heat preservation tank to a vacuum glove box and place it for 24 hours. Collect the prepared nano silicon powder. Put the prepared nano silicon powder in the corundum ark, put it into a vertical high-temperature tube furnace, and pass a mixed gas of nitrogen and ammonia as the nitriding gas. The volume ratio of nitrogen to ammonia is 4:6. The flow rate is 500 ml / min, the temperature is increased to 1300°C at a heating rate of 5°C / min, the temperature is kept for 10 hours, and then cooled to room temperature. The silicon nitride nanowires are collected. The diameter of the silicon nitride nanowires is 25nm and the length is 45μm.

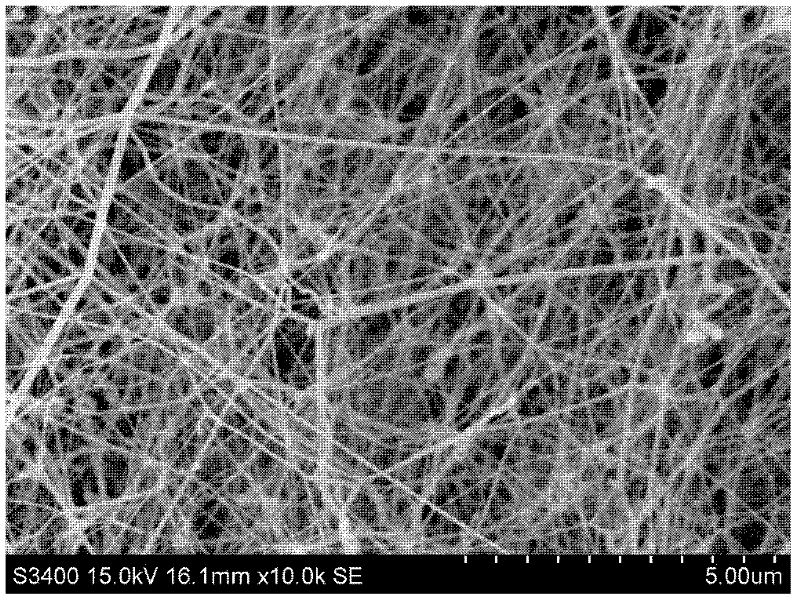

[0041] by image 3 It can be seen that the final product obtained in this embodiment is a silicon nitride nanowire.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com