Method for preparing sodium chloride and powdery barium salt by using salting-out mother liquor generated in zinc powder method

A zinc powder method, sodium chloride technology, applied in the direction of alkali metal chloride, thiosulfate/dithionite/polythionite, calcium/strontium/barium sulfate, etc., can solve the cost of recovering salt Improve and recover the low quality of salt, secondary pollution and other problems, to achieve the effect of simple production process and equipment, high quality of recovered salt, and pollution control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

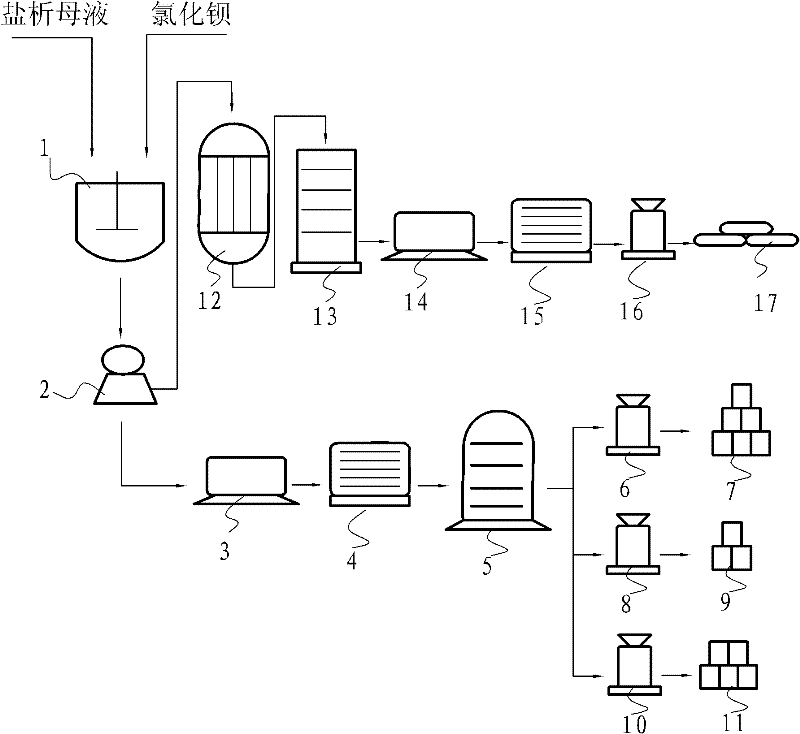

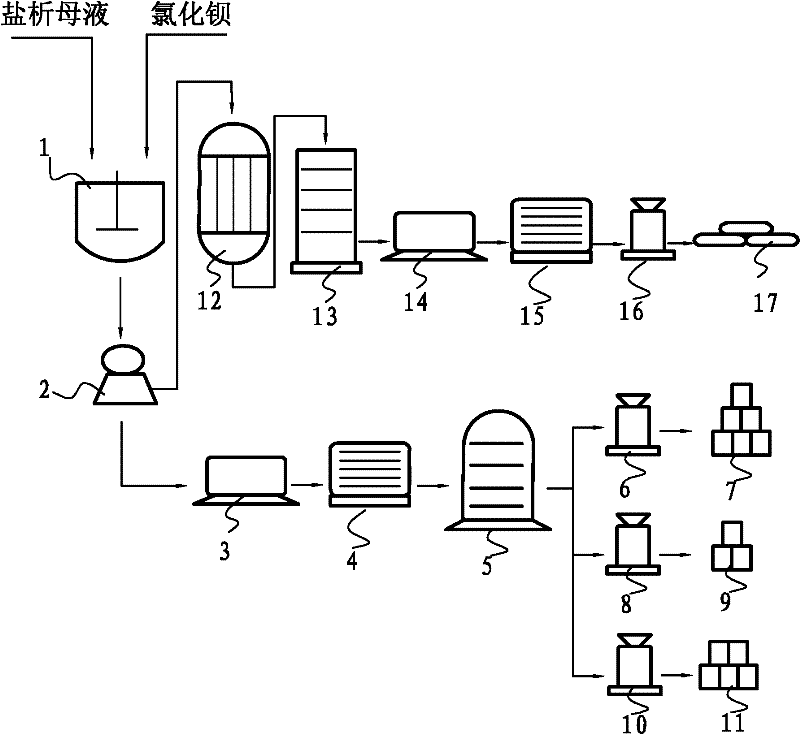

[0022] The method for preparing sodium chloride and powder barium salt with the salting-out mother liquor in the zinc powder method is characterized in that: comprising the following preparation steps:

[0023] Step A, put 1000 liters of salting-out mother liquor and barium chloride solution in the zinc powder method into corrosion-resistant reactor 1 according to the mass ratio of pure substance 1: 0.95 (wherein containing sodium sulfite 40Kg, sodium dithionite 20Kg, sodium sulfate 10Kg, calculated according to the mass ratio of sodium sulfite to barium chloride 1:0.95, the mass ratio of sodium dithionite to barium chloride 1:0.95, and the mass ratio of sodium sulfate to barium chloride 1:0.95, the required input Barium chloride is 66.5Kg), constantly stirring; Reaction generates the mixed solution of sodium chloride, barium sulfite dithionite barium dithionite and barium sulfate;

[0024] Step B, filter the mixed solution obtained in step A with a filter 2;

[0025] Step C,...

Embodiment 2

[0029] The method for preparing sodium chloride and powder barium salt with the salting-out mother liquor in the zinc powder method is characterized in that: comprising the following preparation steps:

[0030] Step A, put 1000 liters of salting-out mother liquor and barium chloride solution in the zinc powder method into corrosion-resistant reactor 1 according to the mass ratio of pure substance 1: 1.65 (wherein containing 250Kg of sodium chloride, 40Kg of sodium sulfite, bis- Sodium sulfite 20Kg, sodium sulfate 10Kg, calculate according to the mass ratio of sodium sulfite and barium chloride 1: 1.65, the mass ratio of sodium dithionite and barium chloride 1: 1.65, and the mass ratio of sodium sulfate and barium chloride 1: 1.65, respectively, Then the barium chloride that needs to drop into is 115.5Kg), keep stirring; Reaction generates the mixed solution of sodium chloride, barium sulfite dithionite and barium sulfate;

[0031] Step B, filter the mixed solution obtained in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com