Multi-functional guar gum derivative for papermaking and preparation method and application for multi-functional guar gum derivative

A guar gum derivative and multi-functional technology, applied in papermaking, textiles, papermaking, paper, etc., can solve problems affecting retention and drainage, enhancement effects, complicated procedures, etc., achieve short reaction time and small loss of product viscosity , The effect of high etherification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

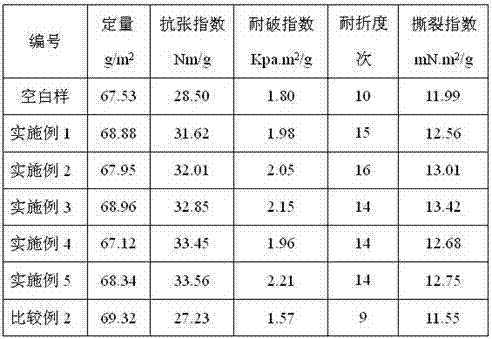

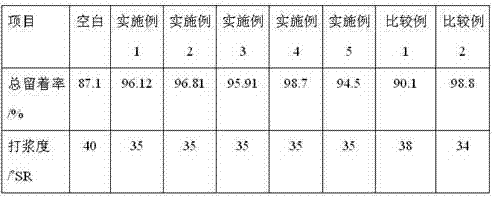

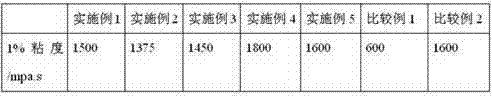

Examples

Embodiment 1

[0036] first step:

[0037]Add 60 grams of urea (1mol) into a three-necked bottle, add 60 grams of distilled water, heat to 50°C, dissolve the urea completely, then add 3 grams of emulsifier OP-10, add 3 grams of sodium carbonate, and ensure that the pH of the material is 8.5, Then add 83.6 grams of epichlorohydrin (the molar ratio of urea to 0.9:1) in 5 times, each interval is 10 minutes, the temperature is raised to 85 ° C, and the reaction is 6 hours to obtain a completely transparent solution, which is concentrated by a rotary evaporator to obtain the amide 136 grams of base nonionic etherification agent; its molecular formula is C 4 h 9 N 2 o 2 Cl (Mw=152.5), when used, it is prepared into a solution with a mass concentration of 60%;

[0038] Step two:

[0039] Add 50 grams of guar collagen powder to 100 grams of industrial alcohol, stir, vent nitrogen, add inorganic alkali solution A, inorganic alkali solution A is formed by mixing 10 grams of water, 1.5 grams of so...

Embodiment 2

[0041] first step:

[0042] Add 52 grams of sodium bisulfite (0.5mol) and 26 grams of sodium sulfite (0.016mol) into a three-necked flask, add 117 grams of distilled water, then add 9.7 grams of emulsifier OP-10, and add an appropriate amount of 1mol / L hydrochloric acid to ensure the pH of the material After that, 57.3 grams of epichlorohydrin (the molar ratio of sulfite ion is 1.2:1) was added in 10 times, with an interval of 5 minutes between each time, the temperature was raised to 50 ° C, and the reaction was carried out for 8 hours until the oil droplets of epichlorohydrin After disappearing, continue to react for 2h to obtain a completely transparent solution, and obtain 100 grams of sulfonate anion etherifying agent after being concentrated by a rotary evaporator; the molecular formula of this intermediate is C 3 h 6 ClO 4 NaS (Mw is 196.5), when used, it is prepared into a solution with a mass concentration of 60%;

[0043] Step two:

[0044] Add 45 grams of guar c...

Embodiment 3

[0046] first step:

[0047] Add 60 grams of urea (1mol) into a three-necked bottle, add 60 grams of distilled water, heat to 50°C, dissolve the urea completely, then add 6 grams of emulsifier AEO-7, and add 2.0 grams of sodium carbonate to ensure the pH of the material is 7.5. After that, 111.4 grams of epichlorohydrin (the molar ratio of urea and urea is 1.2:1) was added in 5 times, with an interval of 10 minutes between each time, the temperature was raised to 90°C, and the reaction was carried out for 5.0 hours to obtain a completely transparent solution, which was concentrated by a rotary evaporator to obtain 137 grams of amide-based nonionic etherification agent;

[0048] Step two:

[0049] Add 50 grams of guar collagen powder to 250 grams of tert-butanol, stir, ventilate nitrogen, add inorganic alkali solution A formed by mixing 12 grams of water, 1.5 grams of sodium phosphate and 4.0 grams of sodium hydroxide, stir at room temperature for 90 minutes to alkalize , then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com