Method for preparing polypyrrole/graphene composite film material

A technology of graphene composite and thin film materials, which is applied in the direction of electrolysis process, electrolysis components, electrolysis organic production, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Prepare the electrolyte: weigh 2.225g of dioctyl sodium sulfosuccinate (AOT), add 100ml of deionized water to prepare a 0.05M AOT electrolyte, and stir for 30 minutes with a magnetic stirrer. According to the mass percentage of pyrrole and graphene being 90%: 10%, add 0.038g graphene to the electrolyte solution, and put it aside for 10 minutes to obtain a uniformly dispersed mixed solution.

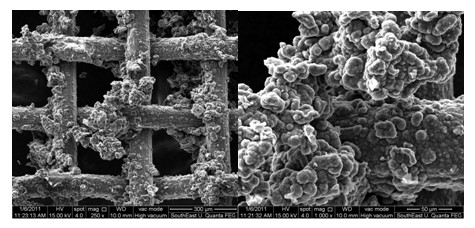

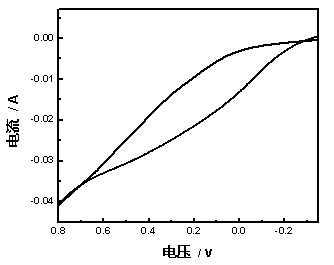

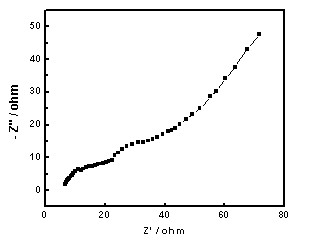

[0029] (2) Preparation of polypyrrole / graphene composite material: Weigh 0.345g (0.1M) pyrrole monomer into the above mixed solution, and stir magnetically for 10 minutes. The polymerization experiment was carried out in a three-electrode system controlled by an electrochemical workstation, with a stainless steel mesh as the working electrode, a platinum sheet as the counter electrode, and a saturated calomel electrode as the reference electrode. The test temperature was (10°C + 2°C). Using a constant potential method, the polymerization voltage is 1V, and the polymerization t...

Embodiment 2

[0033] (1) Prepare the electrolyte: weigh 2.225g of dioctyl sodium sulfosuccinate (AOT), add 100ml of deionized water to prepare a 0.05M AOT electrolyte, and stir for 30 minutes with a magnetic stirrer. According to the mass percentage of pyrrole and graphene being 70%: 30%, 0.148g graphene was added to the electrolyte solution, and a uniformly dispersed mixed solution was obtained after ultrasonication for 10 minutes.

[0034] (2) Preparation of polypyrrole / graphene composite material: Weigh 0.345g (0.1M) pyrrole monomer into the above mixed solution, and stir magnetically for 10 minutes. The polymerization experiment was carried out in a three-electrode system controlled by an electrochemical workstation, with a graphite sheet as the working electrode, a platinum sheet as the counter electrode, and a saturated calomel electrode as the reference electrode. The test temperature was (10°C + 2°C). Using cyclic voltammetry, the polymerization voltage is -0.5 ~ 1.5V, and the poly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com