Method for producing ferrotungsten with tungsten carbide obtained by tungsten-containing waste processing as raw material

A technology of tungsten carbide and tungsten waste, which is applied in the field of producing ferro-tungsten with tungsten carbide as the raw material, can solve the problems of complicated equipment process operation, long smelting time, large floor area, etc., and achieve obvious advantages in economic benefits, less investment in process equipment, The effect of less water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

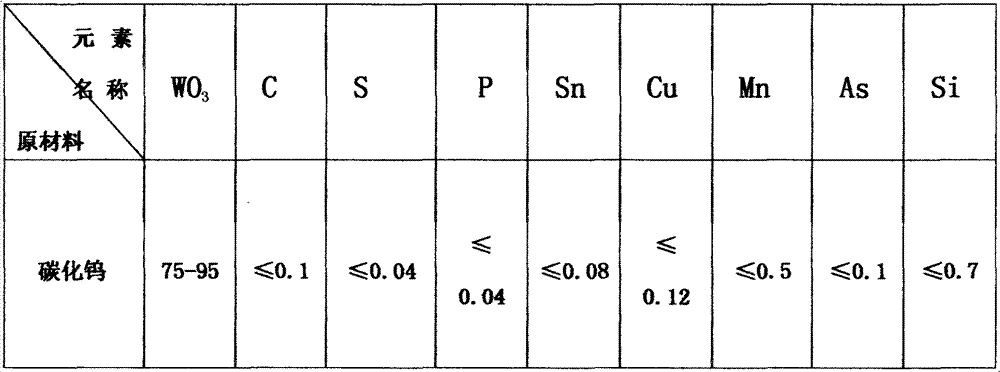

[0027] 1. Put tungsten carbide powder with a particle size of 40 mesh into a resistance furnace, heat it up to 450°C, and keep it warm for 18 hours to obtain tungsten trioxide, cool and discharge.

[0028] 2. Ingredients in the following proportions (unit: kg):

[0030] Iron powder: 143

[0031] Aluminum powder: 170

[0034] 3. Pour the prepared materials into the mixer for 14 minutes to mix the materials evenly.

[0035] 4. Pour the mixed materials into the reaction furnace body, sprinkle magnesium powder on the materials, ignite them with alcohol, and the materials will start spontaneous combustion reaction for 8 minutes, and let stand to cool.

[0036] 5. Use clamps to remove the slag on the upper part of the tungsten alloy, and cool the tungsten-iron alloy with water.

[0037] 6. Crush the tungsten-iron alloy with a jaw crusher.

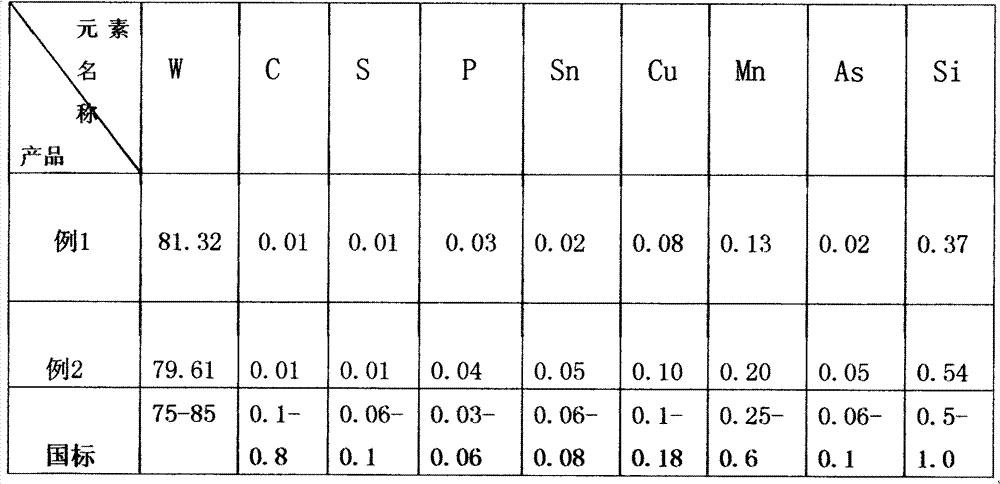

[0038] 7. Sampling and analysis, all indicators meet the requirements, ...

example 2

[0040] 1. Put tungsten carbide powder with a particle size of 30 meshes into a resistance furnace, heat up to 520°C, keep it for 15 hours to obtain tungsten trioxide, cool and discharge

[0041] 2. Ingredients in the following proportions (unit: kg):

[0043] Iron powder: 200

[0044] Aluminum powder: 153

[0046] Calcium fluoride: 11

[0047] 3. Pour the prepared materials into the mixer for 10 minutes to mix the materials evenly.

[0048] 4. Pour the mixed materials into the reaction chamber, sprinkle magnesium powder on the materials, ignite them with alcohol, and the materials will start spontaneous combustion reaction for 11 minutes, and let stand to cool.

[0049] 5. Remove the slag on the upper part of the tungsten alloy, and cool the tungsten-iron alloy with water

[0050] 6. Crush the tungsten-iron alloy with a jaw crusher.

[0051] 7. Sampling and analysis, all indicators meet the requirements, finishing, and packaging acco...

example 3

[0053] 1. Put tungsten carbide powder with a particle size of 30 meshes into a resistance furnace, heat up to 600°C, keep it for 12 hours to obtain tungsten trioxide, cool and discharge

[0054] 2. Ingredients in the following proportions (unit: kg):

[0056] Iron powder: 156

[0057] Aluminum powder: 153

[0058] Calcium oxide: 52

[0059] Calcium fluoride: 19

[0060] 3. Pour the prepared materials into the mixer for 18 minutes to mix the materials evenly.

[0061] 4. Pour the mixed materials into the reaction chamber, sprinkle magnesium powder on the materials, ignite them with alcohol, and the materials will start to spontaneously react for 15 minutes, and let stand to cool.

[0062] 5. Remove the slag on the upper part of the tungsten alloy, and cool the tungsten-iron alloy with water

[0063] 6. Crush the tungsten-iron alloy with a jaw crusher.

[0064] 7. Sampling and analysis, all indicators meet the requirements, finishing, and packaging according to t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com