Adsorbent and preparation method and use thereof

An adsorbent and carrier technology, which is applied in the field of air pollution purification by adsorption technology, can solve the problems of complex process, large floor area, high cost, etc., and achieve the effect of high adsorption efficiency, simple operation and easy realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0028] Clean the 13X molecular sieve three times with deionized water, put it in an oven at 110°C for 1 day, then place it in a muffle furnace at room temperature at a temperature increase rate of 1°C / min to 400°C, roast at 400°C for 8 hours, then The adsorbent is obtained when it is lowered to room temperature.

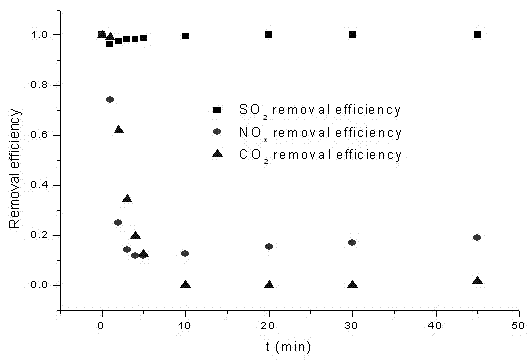

[0029] Place 4g of activated 13X molecular sieve in a 70°C reactor and pass in coal-fired flue gas with a flue gas flow rate of 300 mL / min and SO in the flue gas 2 , NO X And CO 2 The concentrations are 2300ppm, 1100ppm and 11%.

[0030] Monitor the flue gas concentration after purification in real time, and calculate the SO in the flue gas 2 , NO X And CO 2 Purification efficiency, see figure 1 Shown. The desulfurization efficiency is greater than 96%, the denitration efficiency is greater than 12%, and the decarbonization efficiency drops rapidly. In the first 3 minutes, the desulfurization, denitrification and decarbonization efficiencies were maintained at 98%, 25% a...

example 2

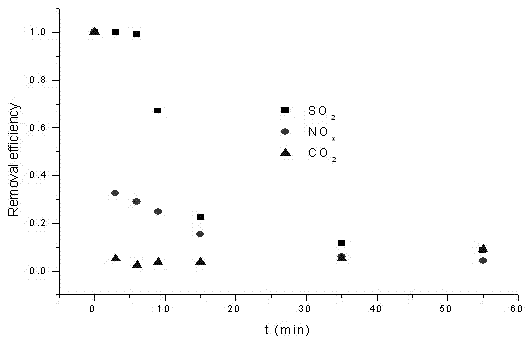

[0032] Clean the 5A molecular sieve with deionized water three times, put it in an oven at 110°C for 1 day, then place it in a muffle furnace at room temperature at a heating rate of 1°C / min to 400°C, roast at the highest temperature for 8 hours, then The adsorbent is obtained when it is lowered to room temperature.

[0033] Put 5g of activated 5A molecular sieve in a 50℃ reactor, and pass in coal-fired flue gas. The flue gas flow rate is 500mL / min. The flue gas contains SO 2 , NO X And CO 2 The concentrations are 2200ppm, 958ppm and 7.7% respectively.

[0034] Monitor the flue gas concentration after purification in real time, and calculate the SO in the flue gas 2 , NO X And CO 2 The purification efficiency, get the purification efficiency, such as figure 2 As shown, the efficiency of desulfurization, denitrification, and decarburization decreased rapidly. The desulfurization, denitrification, and decarburization efficiencies in the first 3 minutes were 67%, 25%, and 3.8%, respec...

example 3

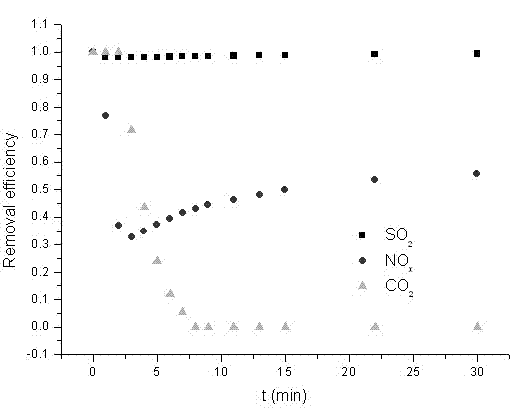

[0036] Add 20g of 13X molecular sieves to 200ml of 1mol / L potassium chloride solution with a solid-liquid ratio of 1:10. Stir for 24 hours at a water bath temperature of 60°C for ion exchange. After repeated washing with deionized water, place it in an oven at 110°C for drying. Day; Put the dried sample in a muffle furnace at room temperature at a heating rate of 1°C / min to raise the temperature to 400°C, and calcine at 400°C for 24 hours. The entire calcination process atmosphere is protected by nitrogen and the nitrogen flow rate is 100mL / min. Finally, the carrier is naturally cooled to room temperature to obtain the desired adsorbent.

[0037] Place 10g of the prepared modified molecular sieve in a 90℃ reactor, and pass in coal-fired flue gas at a flow rate of 300 mL / min, and SO in the flue gas 2 , NO X And CO 2 The concentrations are 2800ppm, 980ppm and 9.2% respectively.

[0038] Monitor the flue gas concentration after purification in real time, and calculate the SO in the fl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| denitrification rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com