High-precision machining deformation control method for titanium alloy spherical shell

A technology of deformation control and titanium alloy, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of lower yield, difficult to meet, processing deformation, etc., to save processing costs, reduce difficulty and workload, The effect of solving the deformation problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A titanium alloy spherical shell with an inner diameter of 600 mm and a wall thickness of 10 mm is machined with the material TC4 stamping part as a blank. The processing accuracy requires that the wall thickness difference is ±0.8m, and the overall roundness tolerance of the spherical shell shall not be greater than 0.5% of the nominal radius.

[0032] The machining scheme of the titanium alloy spherical shell is as follows:

[0033] 1. First, heat-treat the stamped spherical shell at a temperature of 950°C for 2 hours;

[0034] 2. Mark the blank of the stamping part and give the rough machining allowance;

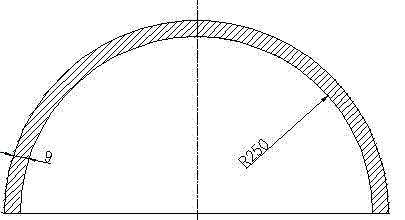

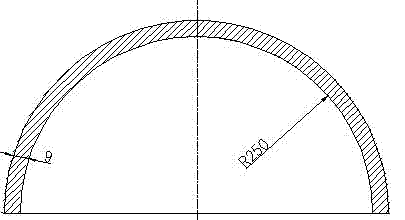

[0035] 3. Roughly process the outer spherical surface first, and then weld the cylindrical clamping tool on the outer spherical surface after the outer spherical surface is processed in place. The diameter of the cylinder is 250mm and the length is 150mm;

[0036] 4. Rough machining of the inner spherical surface;

[0037] 5. Stress relief heat treatment, heat t...

Embodiment 2

[0045] The titanium alloy pressure-resistant spherical shell with an inner diameter of 500mm and a wall thickness of 9mm is machined with the material TC4 stamping parts as the blank. The machining scheme of the titanium alloy spherical shell is as follows:

[0046] 1. Mark the blank of the stamping part and give the rough machining allowance;

[0047] 2. Roughly process the outer spherical surface first, and then weld the cylindrical clamping tool on the outer spherical surface after the outer spherical surface is processed in place. The diameter of the cylinder is 280mm and the length is 170mm;

[0048] 3. Rough machining of the inner spherical surface, rough machining to the 2mm margin of the inner and outer spherical shells;

[0049] 4. Stress relief heat treatment, heat treatment temperature 650 ℃, time 3 hours;

[0050] 5. Semi-finishing, semi-finishing to a unilateral margin of 0.5mm, the tooling is the same as that of the rough machining inner spherical surface;

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com