Method for manufacturing flexible micro electro mechanical system (MEMS) resistance reducing covering

A manufacturing method and flexible technology are applied in the manufacturing field of flexible MEMS drag reduction skins, which can solve the problems of increasing process difficulty and cost, and achieve the effect of reducing processes and simplifying manufacturing processes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

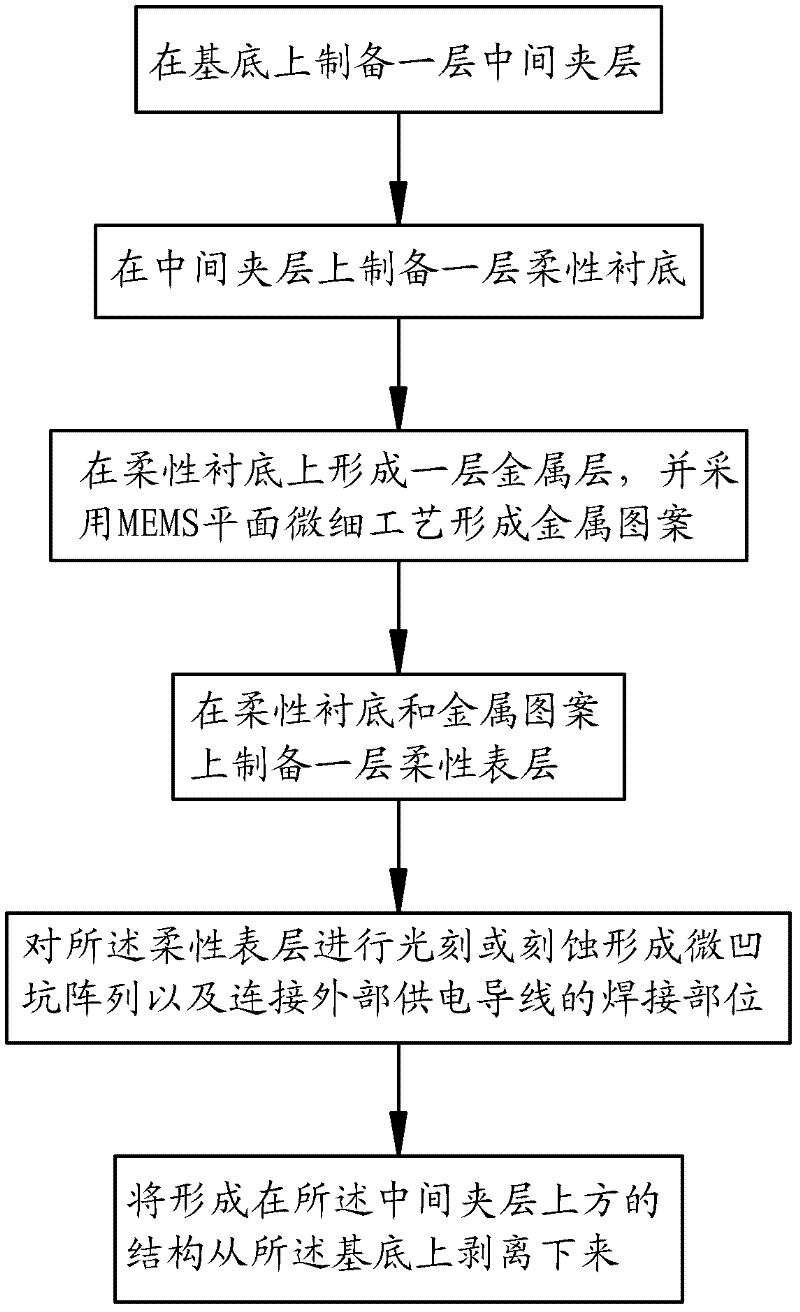

[0046] The manufacturing method comprises the steps of:

[0047] 1.1. Prepare the hard substrate: select ordinary single-polished silicon wafers as the carrier for the entire flexible drag-reducing skin processing.

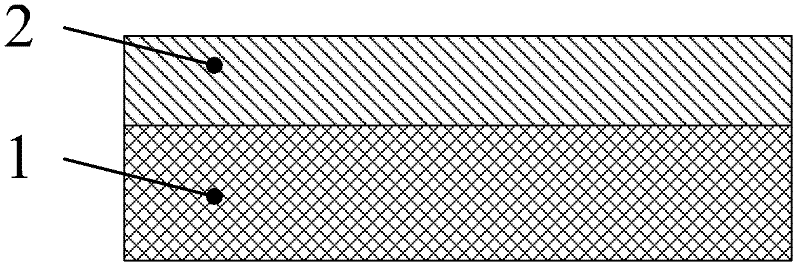

[0048]1.2. Preparation of intermediate interlayer: mix PDMS monomer and curing agent at a ratio of 5:1 to 20:1 by mass of the monomer, stir well and vacuumize for 15 minutes to remove air bubbles in the mixture. Spin-coat the uniformly mixed solution on a hard substrate using a homogenizer, then place it in an oven, and heat it at 90°C for 60 minutes to cure the PDMS. In this step, PDMS films with different thicknesses can be obtained by adjusting the rotation speed of the glue leveling machine and selecting different glue leveling-curing times. The thickness of the PDMS film in this embodiment is 20 μm.

[0049] 1.3. Preparation of flexible substrate: Spin-coat polyimide prepolymer coating glue on the intermediate interlayer, and heat and cure. In this step, p...

Embodiment 2

[0055] The manufacturing method comprises the steps of:

[0056] 2.1. Prepare the hard substrate: choose a polished metal sheet as the carrier for the entire flexible drag-reducing skin processing.

[0057] 2.2. Preparation of the interlayer: mix the PDMS monomer and the curing agent at a mass ratio of 5:1 to 20:1, stir well and vacuumize for 15 minutes to remove air bubbles in the mixture. Spin-coat the uniformly mixed solution on a hard substrate using a homogenizer, then place it in an oven, and heat it at 90°C for 60 minutes to cure the PDMS. In this step, PDMS films with different thicknesses can be obtained by adjusting the rotation speed of the glue leveling machine and selecting different glue leveling-curing times. The thickness of the PDMS film in this embodiment is 200 μm.

[0058] 2.3. Preparation of flexible substrate: Spin-coat polyimide prepolymer coating adhesive on the intermediate interlayer, and heat and cure. In this step, polyimide films with different ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com