Levopimaric acid-stearic acid-pentaerythritol ester synthesis technology

A technology of pentaerythritol ester and L-pimaric acid, which is applied in the synthesis of ester compounds and in the field of organic chemistry, to achieve the effects of less environmental pollution, rich ester-soluble groups, and less toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

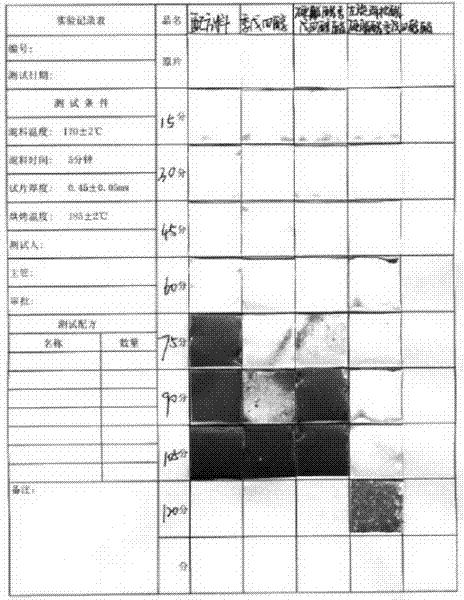

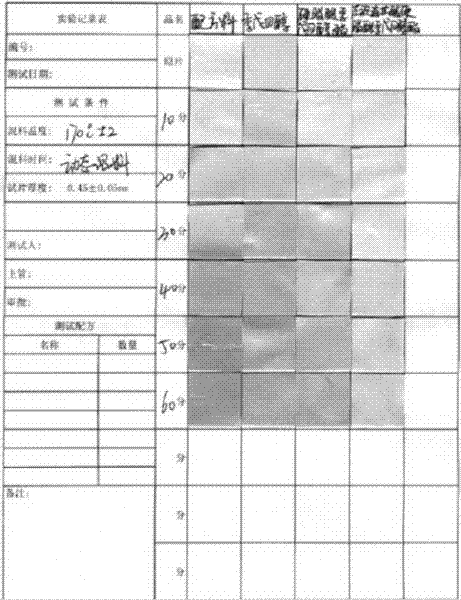

Image

Examples

Embodiment 1

[0022] Example 1: The synthesis of pentaerythritol stearate of levopimarate is carried out according to the following steps.

[0023] 1. Preparation of L-pimaric acid butanolamine salt by ethyl acetate solvent method: Weigh 400g of pine resin and place it in a 2L beaker, add 800ml of ethyl acetate, heat in a water bath at 55°C, after the rosin is completely dissolved, filter it with a 200-mesh filter cloth while it is hot, To obtain a clear rosin solution, cool to room temperature; weigh 75g of butanolamine and place it in a 250mL beaker, add 25ml of water and 7.5ml of ethyl acetate to dissolve completely, and add the clear rosin solution while stirring rapidly to obtain a white precipitate, cool After reaching room temperature, filter under reduced pressure to obtain the amine salt precipitate and amine salt recrystallization mother liquor; wash the amine salt precipitate with clean ethyl acetate for 3 times, then dry the precipitate, disperse it on a white enamel plate, an...

Embodiment 2

[0026] Example 2: The synthesis of pentaerythritol stearate of levopimarate is carried out according to the following steps.

[0027] 1. Preparation of L-pimaric acid butanolamine salt by ethyl acetate solvent method: Weigh 400g of pine resin and place it in a 2L beaker, add 800ml of ethyl acetate, heat in a water bath at 55°C, after the rosin is completely dissolved, filter it with a 200-mesh filter cloth while it is hot, To obtain a clear rosin solution, cool to room temperature; weigh 75g of butanolamine and place it in a 250mL beaker, add 25ml of water and 7.5ml of ethyl acetate to dissolve completely, and add the clear rosin solution while stirring rapidly to obtain a white precipitate, cool After reaching room temperature, filter under reduced pressure to obtain the amine salt precipitate and amine salt recrystallization mother liquor; wash the amine salt precipitate with clean ethyl acetate for 3 times, then dry the precipitate, disperse it on a white enamel plate, an...

Embodiment 3

[0030] Example 3: The synthesis of pentaerythritol stearate of levopimarate is carried out according to the following steps.

[0031] 1. Preparation of L-pimaric acid butanolamine salt by ethyl acetate solvent method: Weigh 400g of pine resin and place it in a 2L beaker, add 800ml of ethyl acetate, heat in a water bath at 55°C, after the rosin is completely dissolved, filter it with a 200-mesh filter cloth while it is hot, To obtain a clear rosin solution, cool to room temperature; weigh 75g of butanolamine and place it in a 250mL beaker, add 25ml of water and 7.5ml of ethyl acetate to dissolve completely, and add the clear rosin solution while stirring rapidly to obtain a white precipitate, cool After reaching room temperature, filter under reduced pressure to obtain the amine salt precipitate and amine salt recrystallization mother liquor; wash the amine salt precipitate with clean ethyl acetate for 3 times, then dry the precipitate, disperse it on a white enamel plate, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com