Preparation method of composition used for rubber product, and product thereof

A technology for rubber products and compositions, which is applied in the preparation of raw materials for rubber products and compound compositions for rubber products, and can solve problems such as low utilization, pollution, and small evaporation area of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

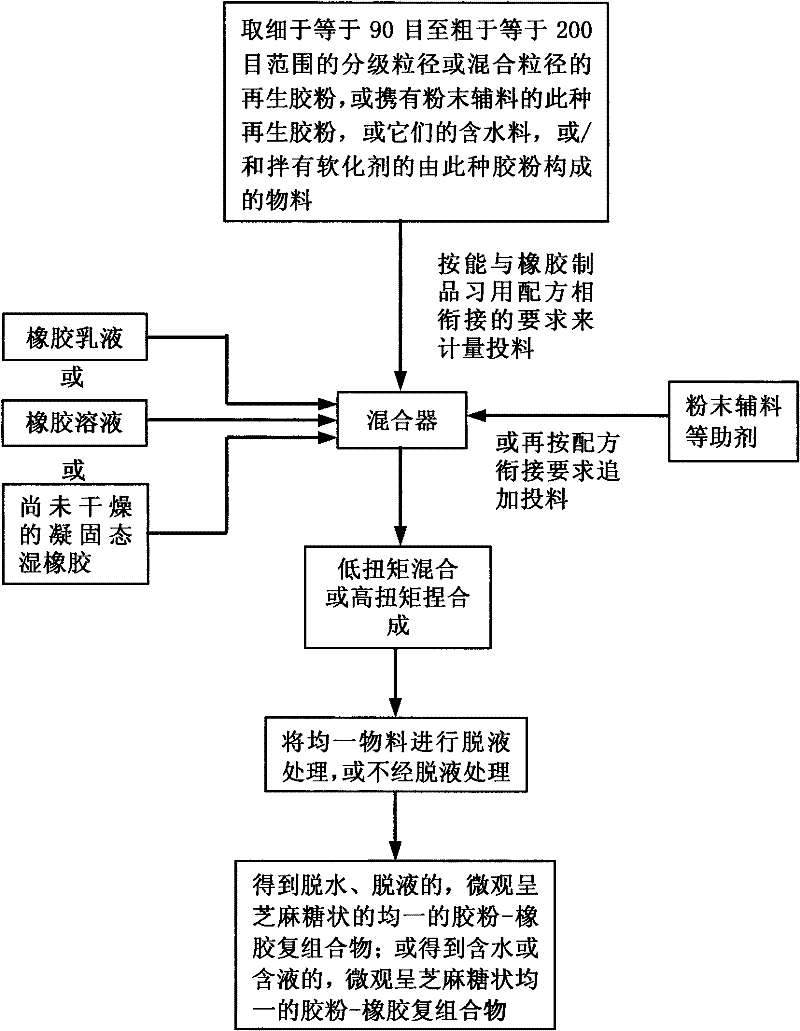

Method used

Image

Examples

Embodiment 1

[0072] Prepare the rubber powder-rubber compound composition of 233 weight parts, concrete steps are:

[0073] 1-1. Preparation of mixed powder of rubber powder and powder auxiliary materials: 100 parts by weight of waste tire tread rubber particles of 20 to 30 mesh (that is, regenerated waste rubber vulcanized rubber particles, the same below), mixed with waste tires finer than or equal to 200 mesh 33 parts by weight of pyrolysis carbon black of tire side rubber and nylon miscellaneous fibers in waste tires, add emulsifier (optional sodium stearate or / and polyoxyethylene fatty alcohol ether) 0.033 ~ 1 part by weight, add stearic acid 1 part by weight, after mixing with a stirrer, the formula is pulverized by a known elastic body normal temperature fine grinder (also called: normal temperature disc type fine rubber grinder, the same below), treated with a cyclone classifier and a 100-mesh vibrating screen, and coarsely After the materials are returned and treated, about 133 pa...

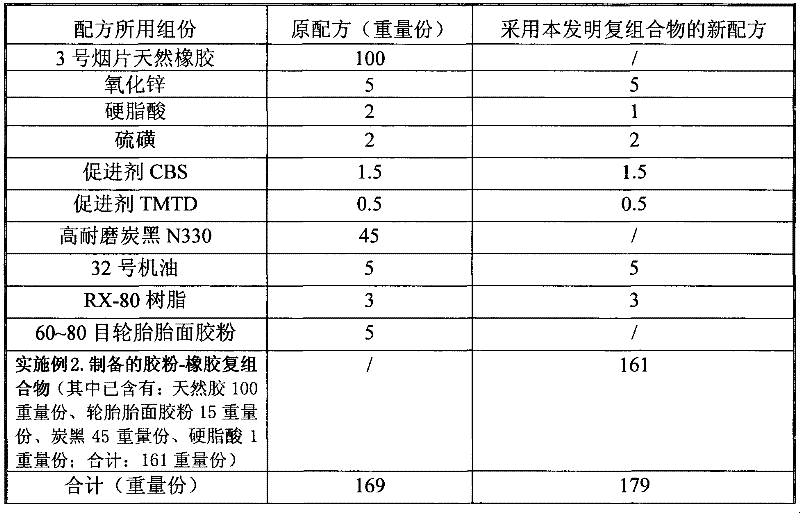

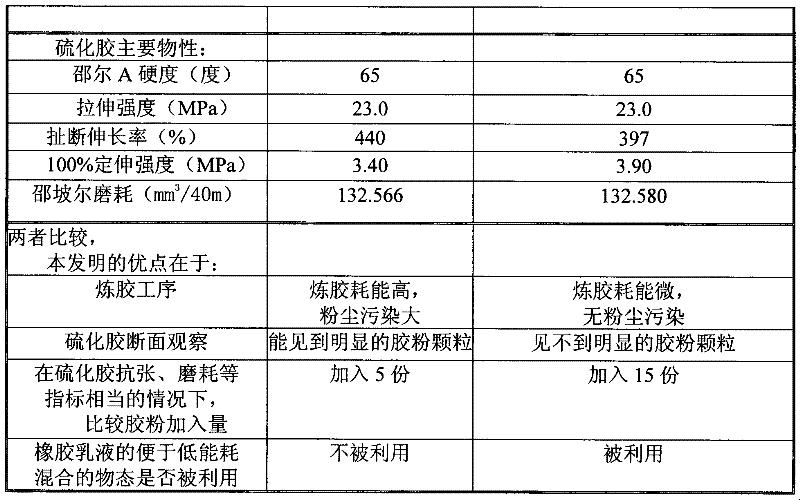

Embodiment 2

[0078] Prepare the rubber powder-rubber composite composition of 160 weight parts, concrete steps are:

[0079] 2-1. Preparation of mixed powder of rubber powder and powder auxiliary materials: use 15 parts by weight of 15-30 mesh waste tire tread rubber particles (i.e. regenerated waste rubber vulcanized rubber particles), and 45 parts by weight of carbon black finer than 1000 mesh , add 1 weight part of surfactant (optional sodium stearate), after mixing with a stirrer, the formula material is pulverized by a known elastomer normal temperature fine crusher, then classified, sieved, and the coarse material is returned to be crushed again. , Obtain about 60 parts by weight of waste tire vulcanized rubber powder and powdered carbon black mixture that is finer than or equal to 100 mesh and contains a surfactant for use.

[0080]2-2. Mixing and coagulation with rubber emulsion: In a stirring mixer not less than 1500L, first pump about 1000L of clear water, and put all the vulcani...

Embodiment 3

[0084] Prepare the rubber powder-rubber compound composition of 194 weight parts, concrete steps are:

[0085] 3-1. Preparation of rubber powder: use 20 parts by weight of waste tire tread rubber particles of 15-30 mesh, 10 parts by weight of white carbon black and 2 parts by weight of carbon black, add anionic surfactant (optional sodium stearate ) 0.01 parts by weight, after mixing with a stirrer, the formula material is pulverized by a known elastomer normal temperature pulverizer, then classified, sieved, and the coarse material is returned to be crushed again to obtain a compound that is finer than or equal to 100 mesh and contains a surfactant About 32 parts by weight of vulcanized rubber powder and powdered white carbon black, carbon black mixture, and then import 38 parts by weight of high wear-resistant carbon black (N330), and then add environmentally friendly rubber filler oil or / and ring 24 parts by weight of paraffin oil or / and machine oil or / and rubber seed oil, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com