Preparation method for wettability controllable porous structure of titanium and titanium alloy surface

A technology with porous surface and titanium alloy, applied in metal material coating process, gaseous chemical plating, coating, etc., can solve the problems of decreased biological activity, decreased bonding strength between coating and substrate, and reduced service life of implants. Achieve the effect of increasing the degree of combination and good timeliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

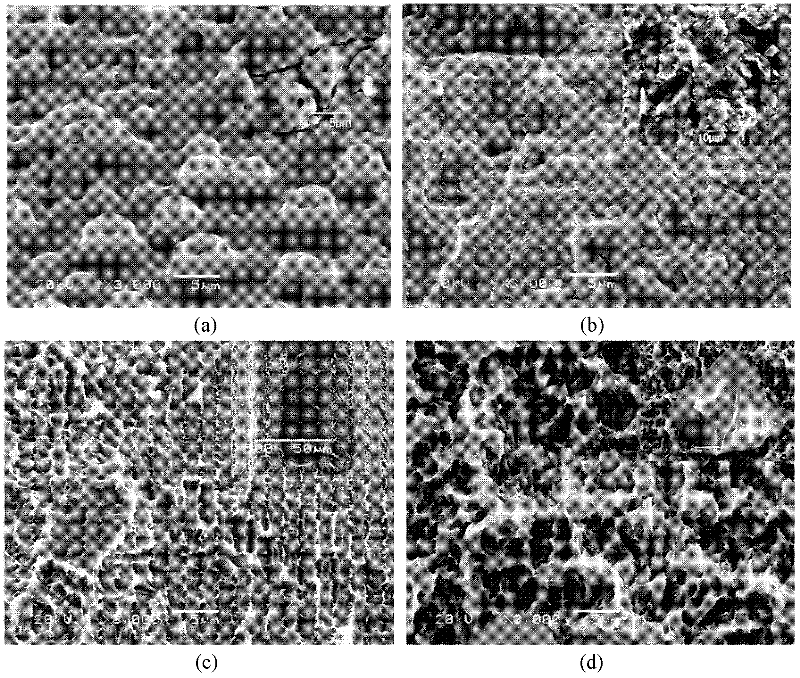

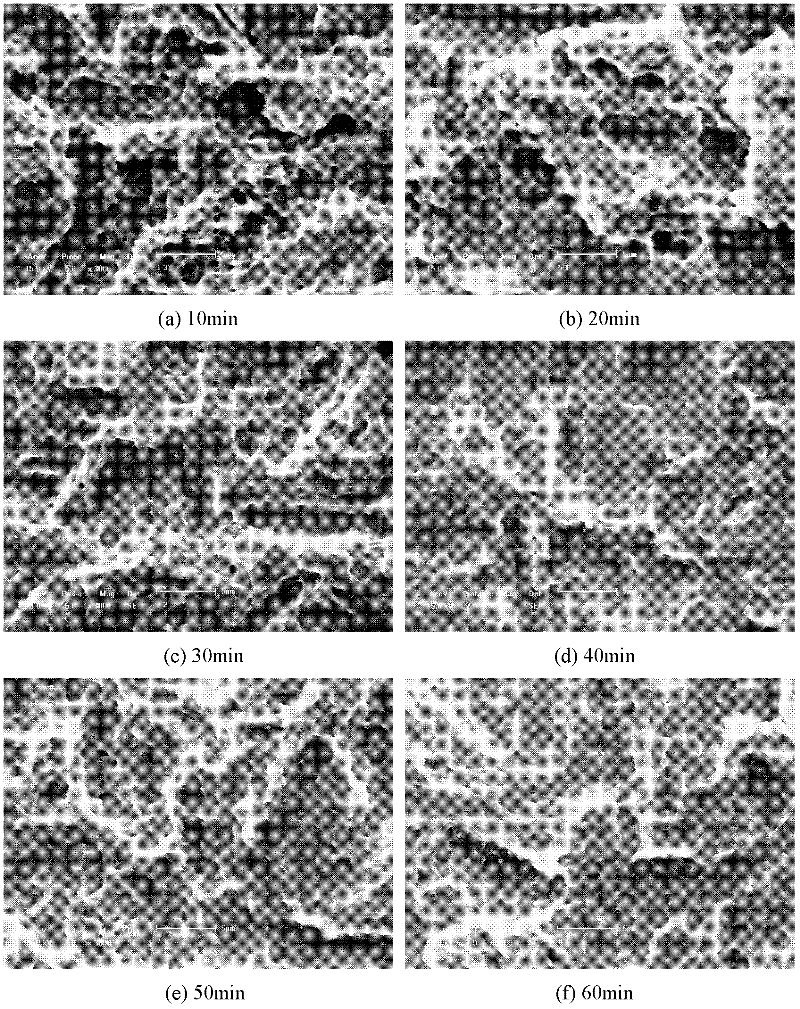

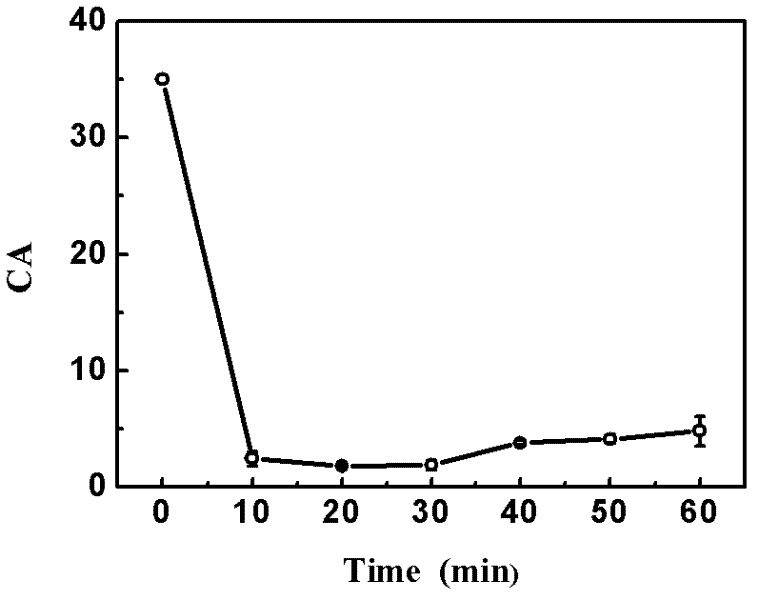

[0036] The TC4 titanium alloy utilizes the SLA method of the present invention to prepare a porous structure, and the specific method is as follows: take the TC4 titanium alloy, and process it through wire cutting, turning, and grinding to prepare a disc-shaped sample, and then after degreasing, polishing, and cleaning processes, the Its sandblasting treatment, the sandblasting treatment time is 30s, after the sandblasting treatment, the surface of the sample piece changes from silvery white metallic luster to dark gray. Then put the sample into the H 2 SO 4 Corrosion is carried out in a mixed solution with HCl, and the mixed acid solution has a volume fraction of 60% H 2 SO 4 and 10% HCl according to the volume ratio of 1:1, the temperature of the acid solution is controlled at 50°C, the corrosion time is 10min, 20min, 30min, 40min, 50min, 60min, and finally the sample after acid corrosion is treated with 5% NaHCO 3 The solution was neutralized until the solution pH=7.

...

Embodiment 2

[0040] TA4 medical pure titanium utilizes the SLA method of the present invention to prepare a porous structure, and the specific method is as follows:

[0041] Take TA4 pure titanium and process it by wire cutting, turning, and grinding to prepare a disc-shaped sample. After degreasing, polishing, and cleaning processes, it is sandblasted. The sandblasting time is 120s. After sandblasting The surface of the sample piece changed from silvery white metallic luster to dark gray. Then place the sample in the H 2 SO 4 Corrosion is carried out in HCl acid solution, and the mixed acid solution is 60% H by volume fraction 2 SO 4 and 10% HCl in a ratio of 1:1 by volume, the temperature of the acid solution was controlled at 75°C, and the corrosion time was 60 minutes. Finally, the acid-etched samples were treated with 5% NaHCO 3 The solution was neutralized until the solution pH=7.

[0042] Figure 4 It is the SEM photo of the surface and the test results of the contact angle of...

Embodiment 3

[0044] TC4 titanium alloy utilizes SLA method of the present invention to prepare porous structure, adopts HF / HNO 3 with H 2 SO 4 / HCl two-step corrosion, the specific method is as follows: take TC4 titanium alloy, and prepare a disc-shaped sample through wire cutting, turning, and grinding machining, and then sandblast it after degreasing, polishing, and cleaning processes, and spray The sand treatment time is 60s, and the surface of the sample piece changes from silvery white metallic luster to dark gray after sand blasting treatment. Then put the sample into HF / HNO 3 After being corroded in the acid solution for 30 sec, the H 2 SO 4 Corrosion in / HCl acid solution, in which HF / HNO 3 The mixed acid is 4% HF and 10% HNO by volume 3 Configured according to the volume ratio of 1:1, the temperature of the acid solution is controlled at 50°C, and the H 2 SO 4 / HCl mixed acid is 60% H by volume fraction 2 SO 4 and 10% HCl in a ratio of 1:1 by volume, the temperature of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com