Beta-cyclodextrin functionalized Fe3O4 magnetic nanometer adsorbent and use thereof

A magnetic nanometer and magnetic nanoparticle technology, which can be used in adsorption water/sewage treatment, other chemical processes, chemical instruments and methods, etc., can solve the problems of difficult separation and recovery, waste of resources, secondary pollution, etc., and achieve good solubility, The effect of small internal mass transfer resistance and strong adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

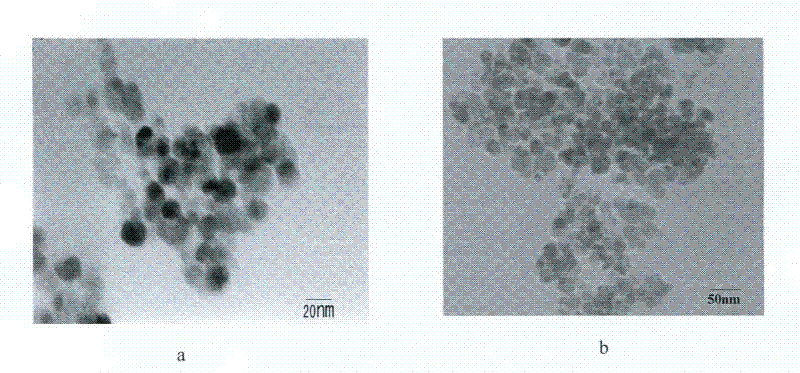

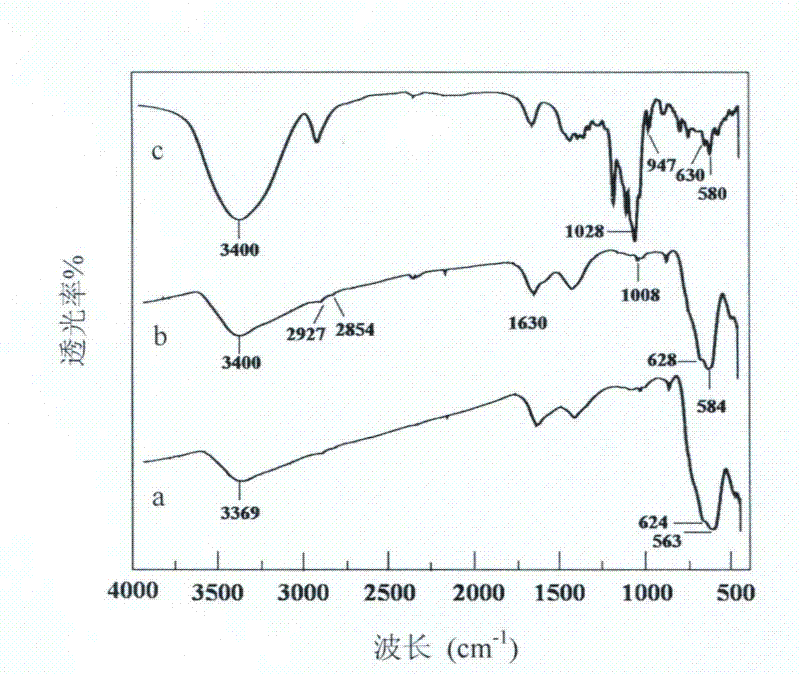

[0031] Example 1: β-cyclodextrin functionalized Fe 3 o 4 Preparation of Magnetic Nanosorbents

[0032] (1) Fe 3 o 4 Preparation of Magnetic Nanoparticles (MNPs)

[0033] Weigh FeCl with a molar ratio of 1:1 2 .4H 2O and FeCl 3 .6H 2 O (total iron concentration 0.3mol / L) is placed in a 250mL round-bottomed flask, add an appropriate amount of twice distilled water 200mL, heat to 80°C, stir rapidly and add 25% ammonia water dropwise to pH 10, cool to room temperature after aging for 30min, Wash three times with double distilled water and 117 mg / mL NaCl solution, separate by permanent magnet, and then dry in a vacuum oven (50°C) to obtain MNP powder.

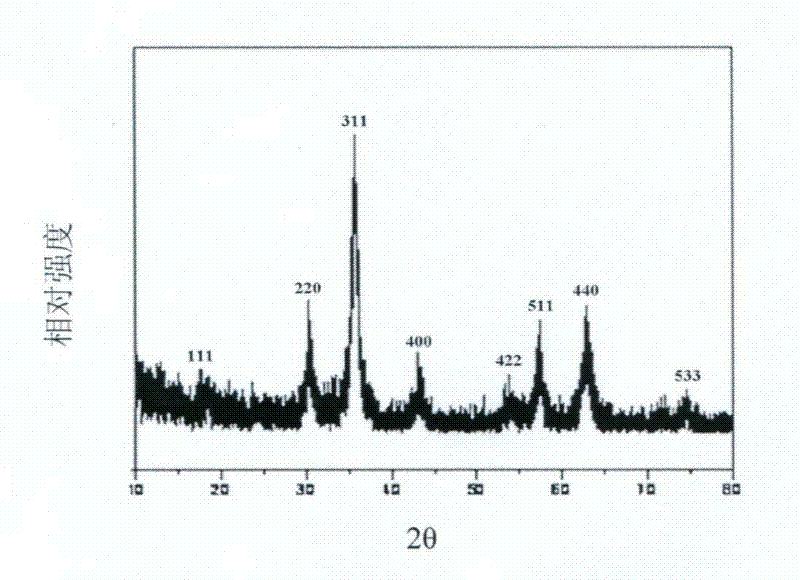

[0034] Characterized by X-ray diffraction technique, it can be seen from the figure that the peaks at 2θ at 30.2, 35.6, 43.2, 53.7, 57.2 and 62.9 correspond to the face-centered cubic Fe 3 o 4 The (220), (311), (400), (422), (511) and (440) diffraction planes, and the standard Fe in JCPDS (No.85-1436) 3 o 4 The phases of...

Embodiment 2

[0049] Example 2: β-cyclodextrin functionalized Fe 3 o 4 Adsorption of Methylene Blue (MB) by Magnetic Nanosorbent

[0050] Take 9.6mg Fe functionalized with β-cyclodextrin 3 o 4 Magnetic nano-adsorbent, add it to 5mL aqueous solution containing methylene blue at a concentration of 0.02mg / mL, adjust the pH of the reaction system to 8, control the temperature at 25°C, ultrasonically disperse for 1 hour, and then fully shake for 8-10 hours. Under the action of an external magnetic field, the fully reacted magnetic nano-adsorbent is separated from the reaction solution, and the supernatant is absorbed at the maximum absorption wavelength of MB at 664nm for ultraviolet spectrum measurement, thereby inferring the content of MB adsorbed by β-CD-MNP .

[0051] Then the same amount of β-CD-MNP (9.6 mg) was added to 5 mL of MB aqueous solution containing different concentrations, the adsorption conditions and adsorption method were the same as above, and the adsorption effect on MB...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com